1

Manufacturing Workforce Development Playbook

Manufacturing

Workforce

Development

Playbook

Preparing for the

manufacturing

renaissance

in America

Edited by Keith S. Campbell

K

eith Campbell’s Manufacturing Workforce Development Playbook is a mul-chapter homage to the

revitalizaon of American manufacturing and how local communies are creang programs to get the

skilled workforce that companies need to build and grow. The authors recognize that workforce needs vary

across regions, but they present enough knowledge so that no one has to start at square one. From creang and

sustaining partnerships to building mul-disciplinary teams to just learning the translaons between “business

speak” and workforce and educaon jargon, reading this book will give you both a validaon of what you have

been doing right and an idea of how to move forward. The book illustrates how workforce professionals build

world-class instrucon and training quickly and then adapt what they have done to meet the ever-changing needs

and priories of their business partners. This is praccal advice from praccing experts, and I believe that the

result is something that every area with a growing manufacturing employer base, regardless of size, can use.

Jane Oates, Vice President for External Affairs, Apollo Group, Inc.

Formerly Assistant Secretary, Employment and Training Administration, U.S. Department of Labor.

“T

he pipeline of talented workers is the single greatest factor in the growth and vitality of our

economy. Campbell’s Playbook is a thorough analysis of how the manufacturing industry is trying to close

its skills gap. Campbell and his contributors prove that the best method to developing a lasng talent pipeline

for manufacturing is to bring together employers, educators, and community leaders to align manufacturing

educaon and training with industry standards.”

Jennifer M. McNelly, President, The Manufacturing Institute

I

t is easy for me to support the Manufacturing Workforce Development Playbook because it focuses much-

needed aenon on the hard work required by all stakeholders if we hope to keep U.S. manufacturing strong.

The Playbook’s message is consistent with my belief that we must all work together for an educated workforce.

Together we can reach our goal of keeping creave, challenging, and excing manufacturing jobs

in the United States.

Nick Wilson, President, Morrison Container Handling Solutions

Reviews

Reviews continue on the back cover

K

eith Campbell’s Playbook clearly arculates the fundamental needs of today’s manufacturers. It’s no secret

that an engaged and skilled workforce is a requirement to be a successful manufacturer. The current workforce

has to have the right skill sets to keep manufacturing a viable contributor to our economy. Each puzzle piece of the

Playbook highlights requirements for educaon, government, and industry to create long-term favorable soluons

to workforce development. We are experiencing a great loss in technical talent with Baby Boomer rerements.

Without suitable replacements, the future of manufacturing is suspect. Keith and his team of authors are

commied to America’s manufacturing prosperity.

Rob Harrison, Pepperidge Farm Plant Manager

Supporters

Copyright © 2014 First Edition, by Summit Media Group, Inc. All Rights Reserved.

Manufacturing Workforce

Development Playbook

Keith S. Campbell

Summit Media Group, Inc.

330 North Wabash Avenue

Chicago, Illinois 60611 USA

Tel: 312.222.1010

Fax: 312.222.1310

ISBN 978-0-9903288-0-3

Cover and book design by Filippo Riello

Printed in the United States of America

A portion of net proceeds of this book will go

to the David A. Harvey Memorial Scholarship

to help fund workforce development efforts.

Materials in the publication must not be reproduced in any form

without written permission of the publisher.

Additional copies are available at the IoPP bookstore at http://www.iopp.org/bookstore

Discounts available for educational and not-for-prot organizations.

Please contact Summit Media Group at workfor[email protected] or go to

http://www.packworld.com/workforce for more information.

Manufacturing

Workforce

Development

Playbook

Preparing for the

manufacturing

renaissance

in America

Edited by Keith S. Campbell

Table of Contents

Before You Begin

Foreword by Keith S. Campbell

How to approach this Playbook and solve your puzzle.

Why this Playbook?

Chapter One by Daniel W. Fogarty

The crical shortage of manufacturing skills due to changes

in demographics, technology, and atudes.

Manufacturing is Complicated

Chapter Two by Keith S. Campbell

There are no one-size-ts-all soluons. Know your needs

and know your customers.

Manufacturing Career Pathways

Chapter Three by Sco J. Sheely

Where do manufacturing workers come from,

and how do they advance?

Preparing America for 21st Century

Global Compeveness

Chapter Four by William C. Symonds

The Pathways to Prosperity Report from the Harvard Graduate School of

Educaon points out where America stands on a global basis and suggests

changes we need to make.

The Role of the Workforce System

and How it has Changed

Chapter Five by Edward J. McCann

The system has changed, and those of us who have always been employed

may have missed that fact.

Manufacturing: By the Numbers

Chapter Six by Sco J. Sheely

Data can help manufacturers jusfy their needs and help educators

put the right programs in the right place.

p. 12

p. 14

p. 22

p. 30

p. 36

p. 42

p. 48

Perspectives

Table of Contents

p. 56

p. 62

p. 70

p. 78

p. 84

p. 92

p. 98

p. 104

Skill Standards, Not Curriculum Standards

Chapter Seven by John DeVere

Schools must provide a product that meets customer needs by idenfying the

appropriate skill requirements, not forcing students through idealized curricula.

Success in the New Economy

Chapter Eight by Kevin J. Fleming, Ph.D.

A post high-school credenal for all is a beer message

than college for all.

Training and College Credit

Chapter Nine by Carol Adukais, Ed.D.

According to best pracces, students should obtain college credit

for workforce training and prior knowledge.

The Role for Industry Credenals

Chapter Ten by Gardner A. Carrick

Manufacturing lacks industry-recognized credenals relave to other sectors.

NAM is trying to change that.

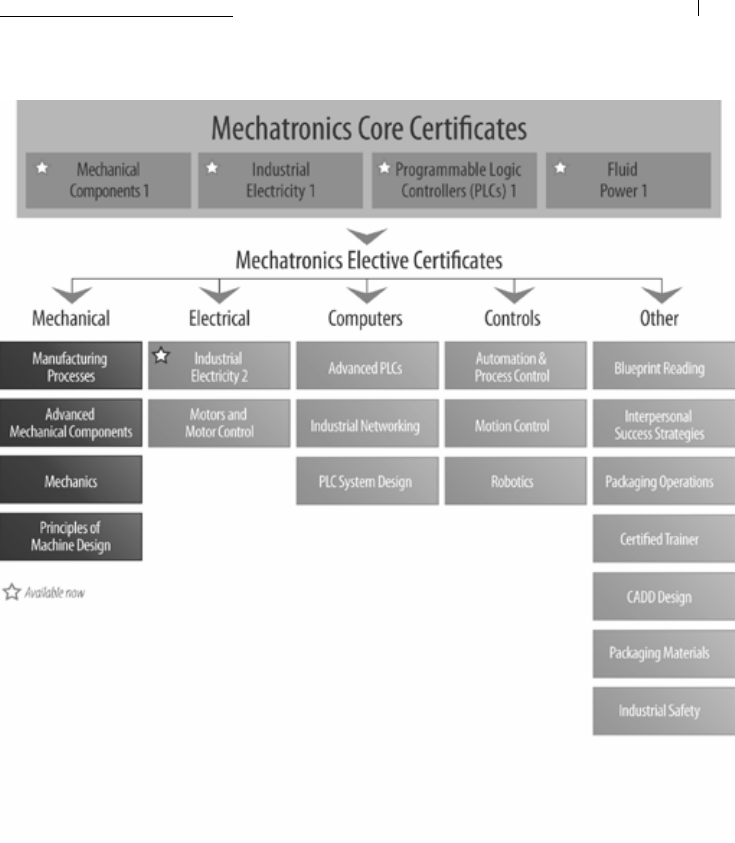

PMMI’s Mechatronics Cercaon Program

Chapter Eleven by Maria Ferrante

PMMI has stepped up to create credenals for manufacturing

where none existed.

Veterans—One Soluon to the

American Manufacturing Skills Gap

Chapter Twelve by Mike Aroney

Translang skills learned in the military to manufacturing.

Working Together for Manufacturing Workforce Development

Chapter Thirteen by Bonnie L. Spayd

Bringing the right pares to the table for open communicaons

can result in extremely successful programs.

A Look at the Learners

Chapter Fourteen by Pat Reynolds

We can’t forget the students. What are their needs and opinions?

Table of Contents

What the Future Workforce Doesn’t Know

Chapter Fieen by Simon Nance

Building awareness about how cool manufacturing really is.

JumpStart Shows Kids that Manufacturing is Cool

Chapter Sixteen by Michele Bupp

Geng youth interested in manufacturing careers.

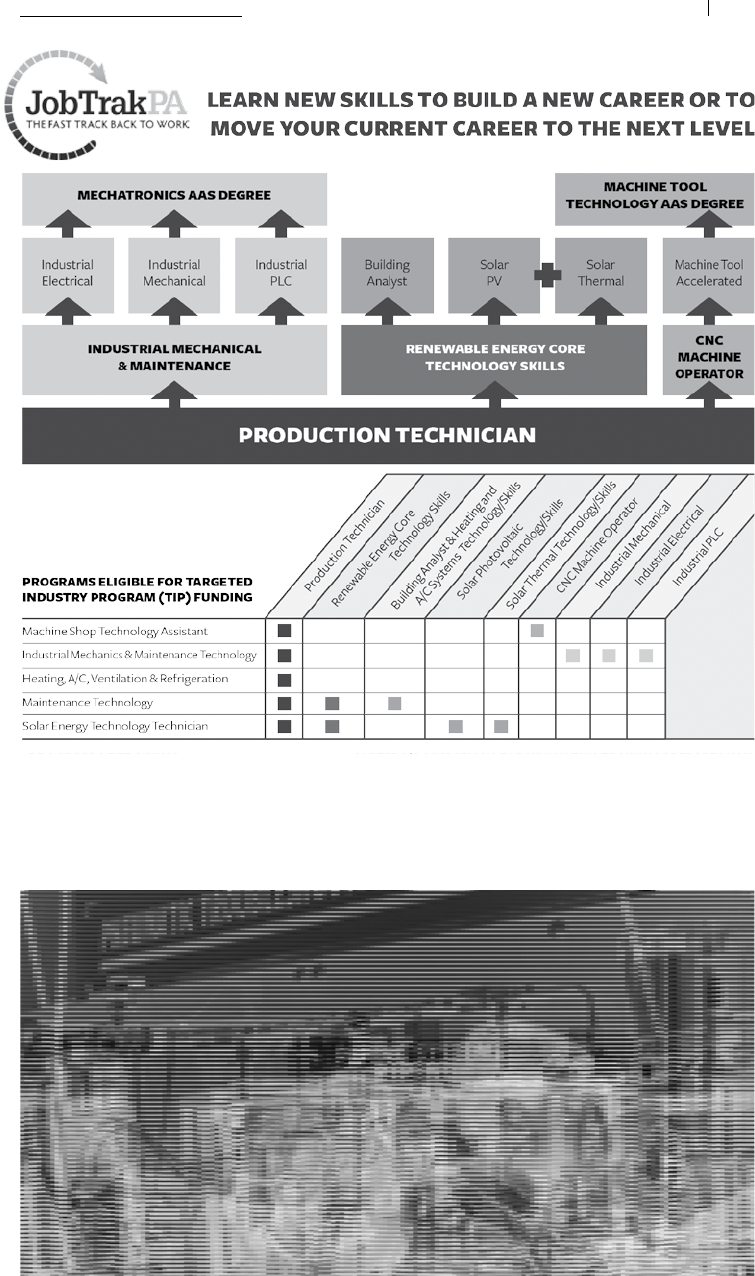

Careers in 2 Years: Go From Learning to Earning Fast

Chapter Seventeen by Jon Sco

A local economic development partnership promotes

manufacturing careers to kids.

The Path from High School to Gold Collar Career

Chapter Eighteen by Kevin Lipsky

Students need guidance to help them make the choices that lead to a

sasfying and successful career.

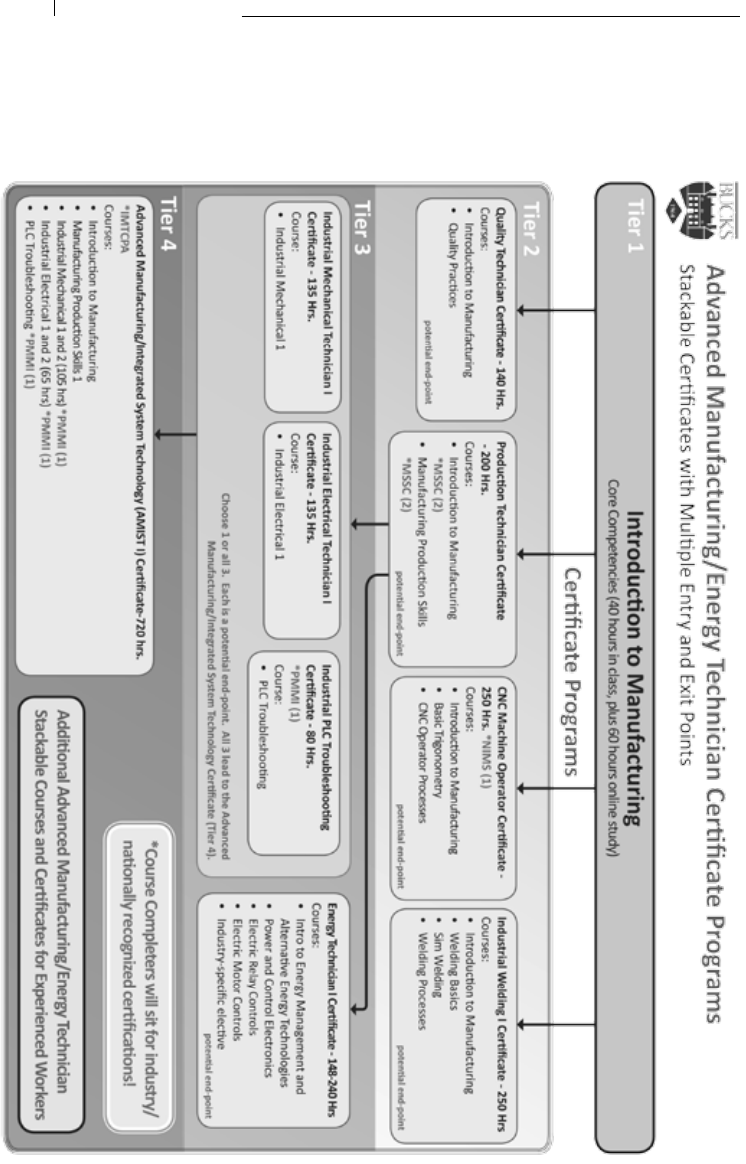

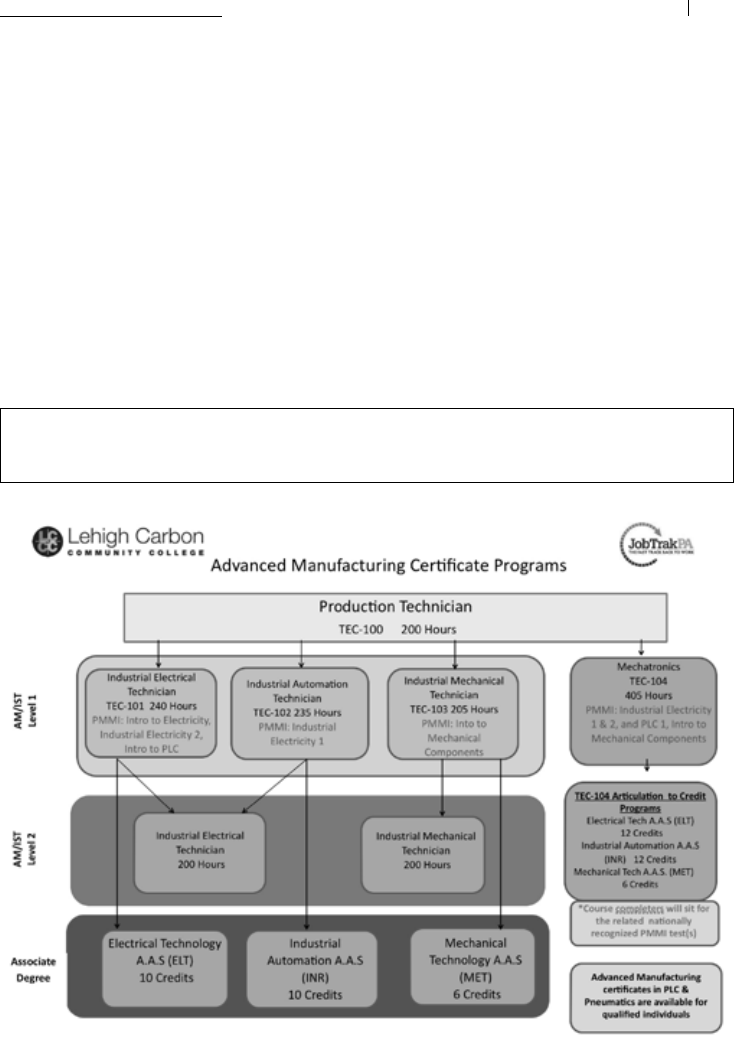

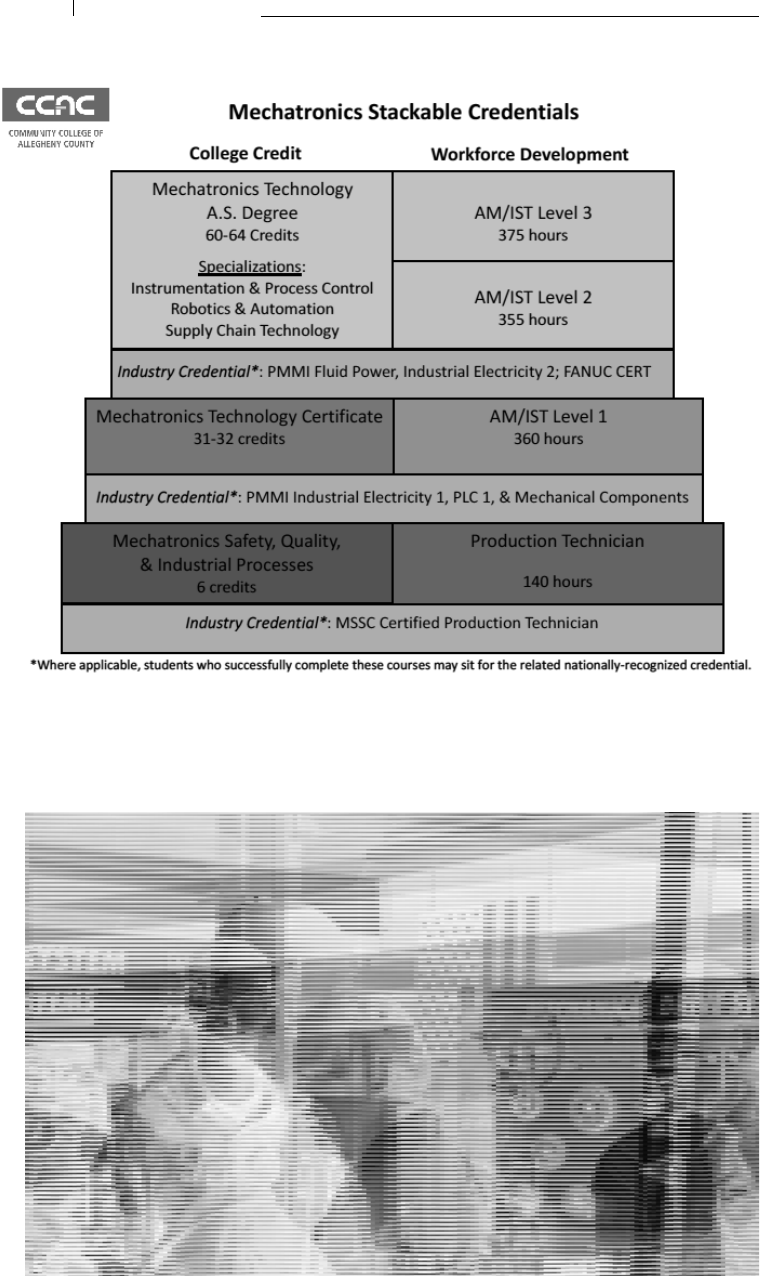

Stackable Credenals at Work for Manufacturing

Chapter Ninteen by Emily Evans

A community college builds the capability to serve mulple industries

and address the needs of students on mulple pathways.

21st Century Manufacturing Success Depends on

Automaon Technology and a Skilled Workforce

Chapter Twenty by Chris Paynter

Creang a high-tech talent pipeline for Charloe businesses.

A New BS Degree Program: Mechatronics Engineering

Technology is a University Success

Chapter Twenty-one by Dr. Niaz Laf

Universies are slowly seeing the need for applied science programs.

Secondary School Solutions

Community College Solutions

University Solutions

p. 116

p. 124

p. 128

p. 134

p. 140

p. 148

p. 154

Table of Contents

Continuing Education Solutions

Moving Forward

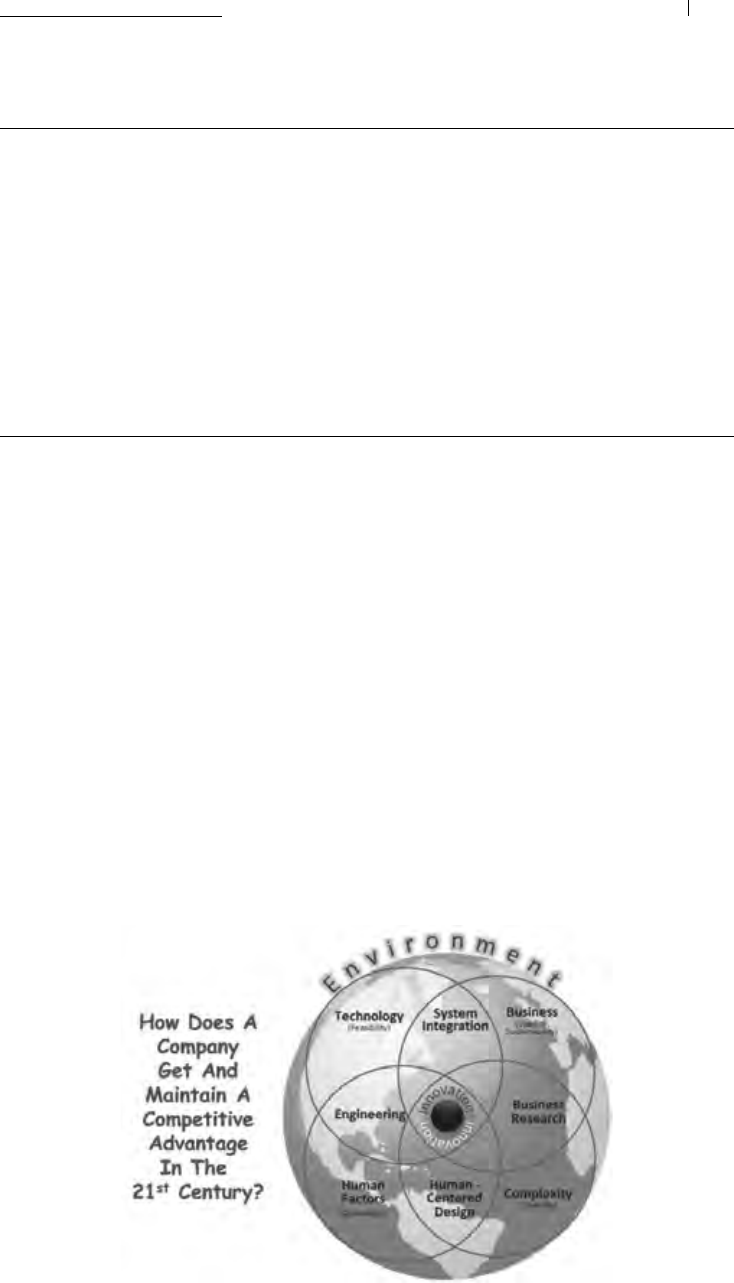

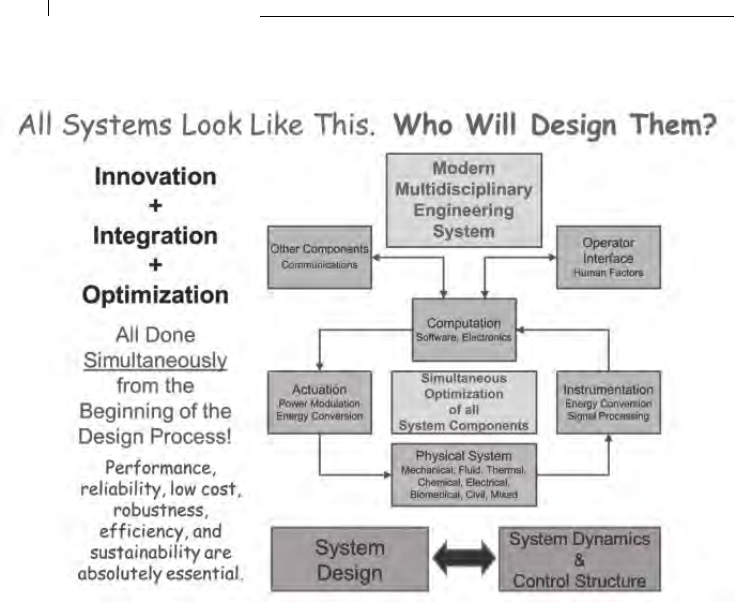

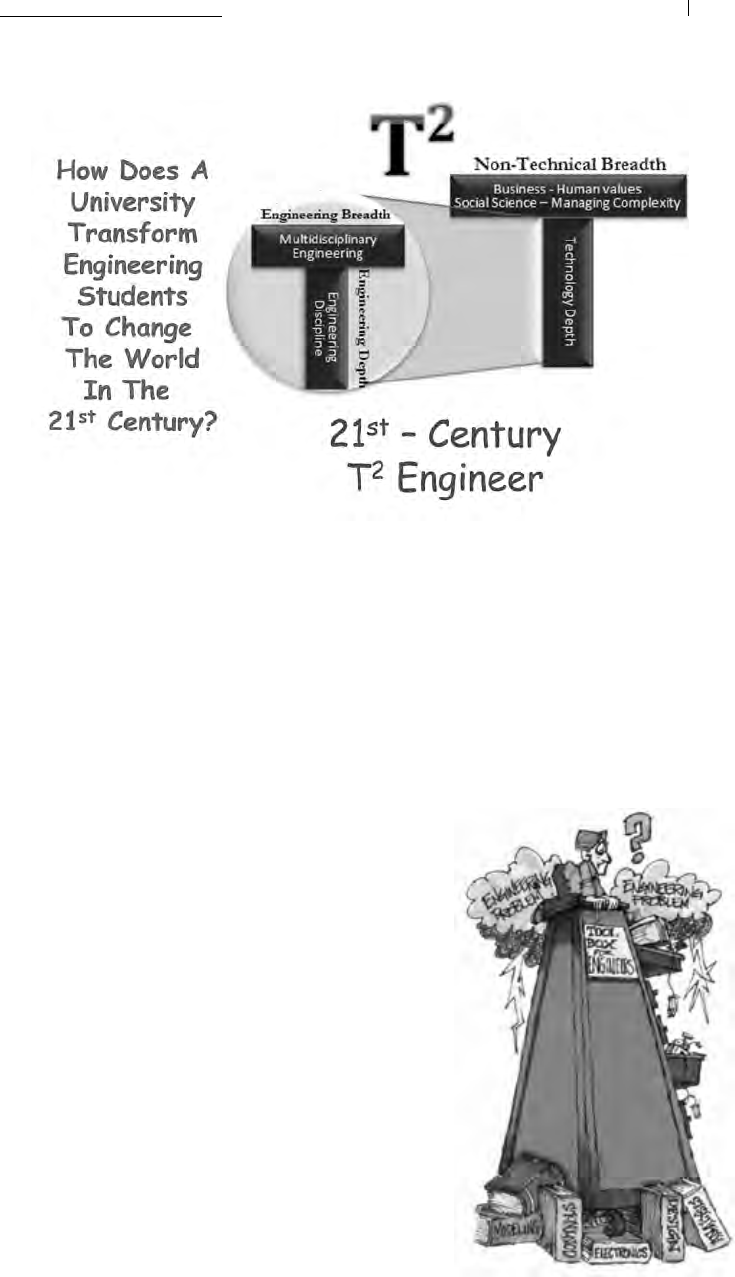

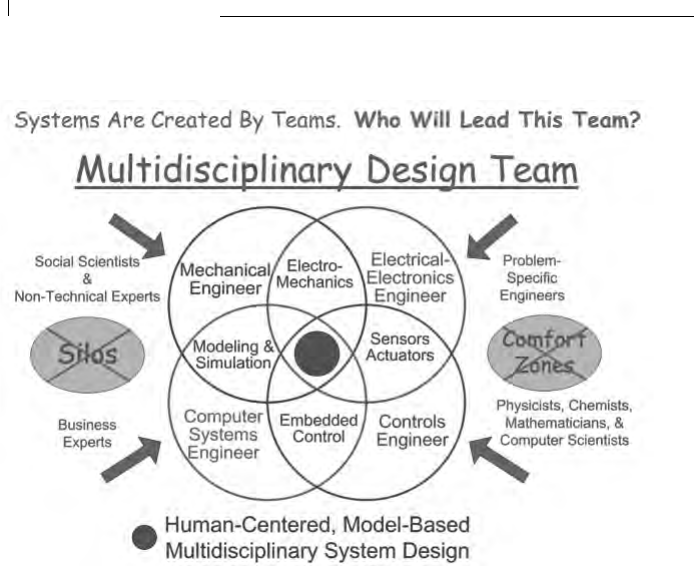

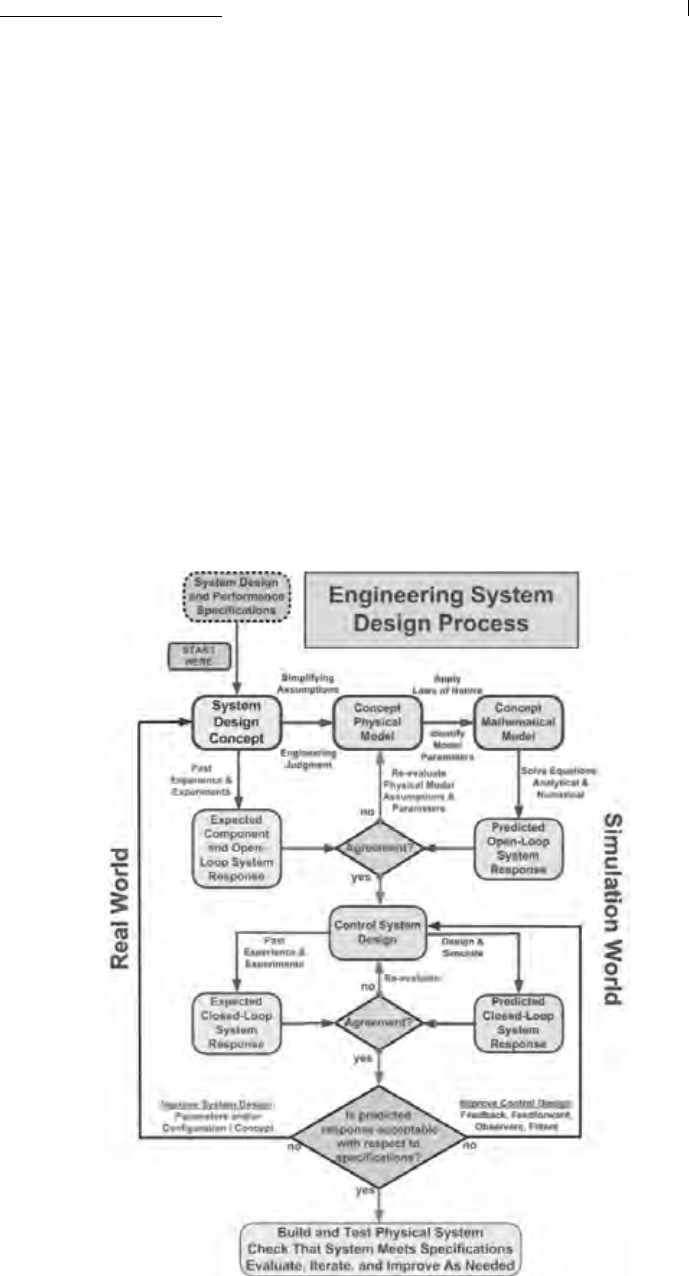

Manufacturing Engineering: Innovaon through

Model-Based Design and Integraon

Chapter Twenty-two by Dr. Kevin Craig, Ph.D.

A look at engineering science educaon for manufacturing and beyond.

Connuing Educaon’s Role in Career Development

Chapter Twenty-three by Jim George

Examples of lifelong learning focusing on packaging professionals.

What I’ve Learned

Chapter Twenty-four by Keith S. Campbell

Using many of the strategies discussed in this book, I have seen regions

and companies solve their most pressing workforce development needs.

A Path Forward

Chapter Twenty-ve, A compilaon of suggesons from the authors.

A list of things that you can do starng today to address your

workforce issues.

Appendix

A resource list for your journey.

Benefactor Sponsors

Educaonal Sponsors

About Keith S. Campbell

p. 160

p. 166

p. 172

p. 178

p. 184

p. 186

p. 208

p. 214

Our thanks to these organizations for their

sponsorship of the Playbook. A portion of

net proceeds will go to the David A. Harvey

Memorial Scholarship to help fund workforce

development efforts.

Benefactor Sponsors

Amatrol, Inc.

Festo

Morrison Container Handling Solutions

PMMI, The Association for Packaging and Processing Technologies

Rockwell Automation, Inc.

Educational Sponsors

Campbell Management Services LLC

Dorner Mfg. Corp.

Industrial Maintenance Training Center of NA

IoPP

Omega Design Corp.

Pro Mach, Inc.

Spee-Dee Packaging Machinery, Inc.

Foreword

I

always told both my kids and my professional sta, “If you are going to play the game,

make sure you know the rules.” For example, for engineers to jusfy a manufacturing

automaon project, they had beer know the rules that the VP of Finance uses to

evaluate the proposal. You can’t expect to do well or win at someone else’s game unless

you understand their rules.

This applies directly to manufacturing workforce development. There are at least three

constuencies that need to be involved to solve the workforce development crisis in

America: industry itself, the educaon system, and government through its naonal, state,

and regional workforce and economic development boards. And we can’t forget the most

important constuents, the customers—those workers, students, and parents of students

who must navigate the choices made available to them for their best advantage.

Aer spending 30 years in industry and 10 years working with educators and workforce

development praconers, I can guarantee you that the rules that these groups play by are

VERY dierent. That is not to say that any of them are bad, just dierent. If we are to solve

this problem, each group must work to understand the other and then join together to

eect change. Seek rst to understand, and then to be understood.

That is why this Playbook has been prepared, rst to facilitate communicaon and

understanding and then to solve the problem. Solving the problem is like pung together

a big puzzle. Manufacturers may nd workforce professionals too theorecal; workforce

professionals may nd educators not focused enough on employment skills; educators

may nd manufacturers impaent and unwilling to parcipate in the process; and students

may nd that they are the most uninformed of all. All of these viewpoints are real and may

somemes come across in chapters of this Playbook. But that is why we need to present all

sides of the story, looking carefully at each of the puzzle pieces.

The early chapters of the Playbook present perspecves on the manufacturing workforce

crisis and its range of soluons as seen by a parcular author represenng one of these

constuencies. These perspecves have been sequenced to try to create a logical ow of

ideas for someone who doesn’t work across these domains every day. Each author was

Before you Begin

How to approach this Playbook

and solve your puzzle

by Keith S. Campbell

selected by me because, in my experience, he or she brings something construcve to the

soluon. Later chapters in the Playbook present real examples of how these groups have

been able to cooperate to create soluons that work.

Immediately preceding each chapter, you will nd a brief statement, idened with

three puzzle pieces, describing how that chapter ts into the puzzle. That will be followed

by the author’s bio, which includes a snippet about why I chose that individual to

parcipate in this project.

It’s OK if you choose to start out in the middle of the Playbook because a topic there

is of more direct interest to you. Just remember that if you hope to bring about real

change, you may want to revisit other chapters before engaging with all of the pares

around your table.

As we look to the future, we recognize that there are more topics that we would like to

have covered in this rst edion of the Playbook, and we know that there are many more

success stories out there that could be included. Through the magic of e-publishing, we

hope to connue to update the Playbook in the future , so we encourage you to send us

your ideas with recommendaons for addional chapters and authors, along with your

crique of what you see here. You may contact me at: Campbell@PackWorld.com

14

Chapter One

I

n considering who best to set the stage for the Manufacturing Workforce De-

velopment Playbook, I immediately thought of Dan Fogarty. Dan’s father was

the Human Resource Director who, in 1974, permied me to begin my journey

into the world of manufacturing. Following in his father’s footsteps, Dan has a lon-

ger-term view of manufacturing than most. His deep understanding of manufactur-

ing enabled him to lead an eye-opening study in Pennsylvania, the results of which

have become the basis for workforce development acvies across the country.

Dan is currently the Human Resource Manager for Schroeder Industries, an

advanced manufacturing company headquartered in Leetsdale, PA. Schroeder is

widely regarded as an industry leader in the manufacture of hydraulic lters and

lter systems.

Prior to joining Schroeder, Dan served as Director of the Pennsylvania Center for

Advanced Manufacturing Careers from 2009-2011 under the sponsorship of the

Pennsylvania Workforce Investment Board.

Dan previously held a number of human resource management posions with

Pennsylvania employers: Peirce-Phelps, Inc., an electronics distributor in Philadel-

phia; Providian Direct Insurance in Frazer; and Carpenter Technology Corporaon, a

manufacturer of specialty steels, in Reading.

Dan co-chaired the Governor’s Commission on College and Career Success (2005-

2006) and in 2007 was appointed to the Pennsylvania State Board of Educaon,

where he chaired the Commiee on College Access and Aordability unl the end of

his term in 2011. Dan also served on the Pennsylvania Workforce Investment Board

from 2004 – 2009 where he co-chaired the Board’s K-12 Educaon Commiee.

Dan currently serves on the Board of Directors for New Century Careers, the Park-

way West CTC Manufacturing Advisory Commiee, CCAC’s Mechatronics Program In-

dustry Advisory Commiee, and the Southwestern PA Math & Science Collaborave.

Dan is a graduate of the University of Notre Dame, which he aended on a Navy

ROTC scholarship. He has a Master’s Degree in Business Administraon from Saint

Joseph’s University in Philadelphia. Dan lives in Pisburgh with his wife Barbe and

their three children.

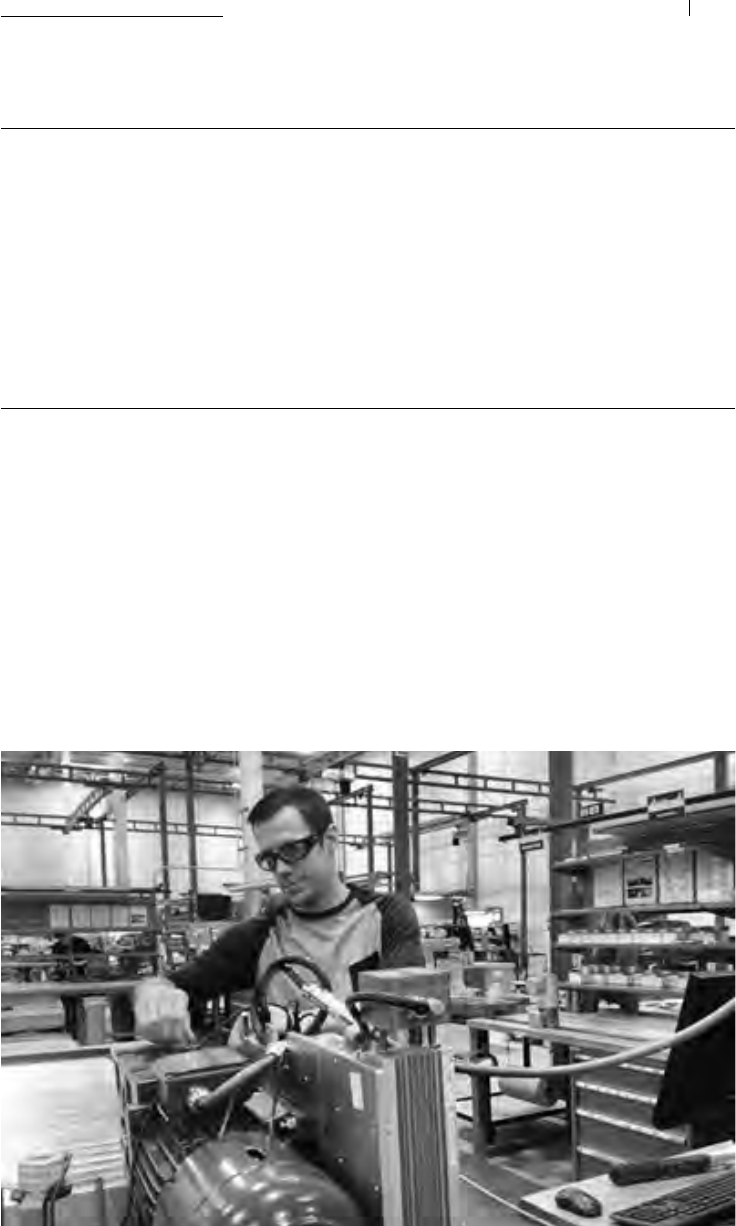

Most Americans think that manufacturing is dead or dying. They see

high unemployment rates. It doesn’t seem logical or possible to them

that there can be a manufacturing workforce crisis in America. Here,

a manufacturer explains the problem that leads to the need for this

Playbook. Recognizing a problem and understanding its causes are the

rst steps toward solving it.

Daniel W. Fogarty,

Human Resource Manager

Schroeder Industries

15

Manufacturing Workforce Development Playbook

Chapter One

T

he U.S. Advanced Manufacturing Skills Gap—

A Consensus and a Reality

I have a bias. I deeply believe that for ambious individuals with the necessary skills,

educaon, and training, now is a great me to begin a career in U.S. manufacturing! I

come to this conclusion based on my own experience as a human resources professional

working for two U.S.-based manufacturers. One is a successful mulbillion-dollar specialty

steel producer. The other is my current employer, a smaller advanced manufacturing rm

located along the Ohio River outside of Pisburgh.

My human resources colleagues in the manufacturing sector nearly unanimously see the

same opportunies. Our reality is that, through the ups and downs of the business cycle,

it has become increasingly dicult to ll good-paying manufacturing jobs because of a lack

of qualied candidates, especially for the skilled manufacturing technicians upon which our

modern technology-driven factories depend. My colleagues and I also share the convicon

that these skills shortages will worsen over the next decade, as many of our most highly

skilled workers will rere.

Having survived two bruising decades of transion caused by rising internaonal com-

peon, U.S. manufacturing execuves that I meet with are opmisc regarding the long-

term prospects of our sector. (Many of their European counterparts share this opmism

and have been acvely invesng in North American manufacturing.) However, our worry

is that our failure to address the manufacturing workforce skills gap could derail plans for

long-term growth and investment here.

If the concern about the skills gap in U.S. manufacturing was conned to conversaons

among those of us in an outdated and declining industrial sector, perhaps we could be

wrien o as just another narrow special interest unwilling to face 21st century economic

realies. Fortunately, this is not the case. We employers are joined by most economic and

workforce development professionals (and a smaller number of farsighted educators) who

understand the importance of a highly producve and expanding advanced manufacturing

sector to our naonal and regional economic well-being. These experienced profession-

als have worked with all economic sectors and bring an objecve perspecve and current

Why this Playbook?

The critical shortage of manufacturing skills is due to

changes in demographics, technology, and attitudes.

by Daniel W. Fogarty

16

Chapter One

research data to support our view. Some of the best workforce development leaders and

educators in the business have contributed to this Playbook.

Over the past decade, many public policy makers have gained a beer understanding of

the need to understand and respond to the rapidly changing workforce needs of manu-

facturing employers, and this was driven home to me at a very unlikely me and place. In

April 2009, I represented my former employer at a manufacturing roundtable discussion

convened by Pennsylvania’s Department of Labor & Industry (L&I) in conjuncon with the

state’s Department of Community and Economic Development (DCED). We were in the

trough of the great recession, and like almost all U.S. manufacturing employers, we faced

rapidly declining sales, yawning excess producve capacity, and a dramac lack of work

for producon employees. When asked by public ocials what could be done to help,

manufacturers reported that our most urgent priority was to nd new orders—a challenge

we understood that the state agencies were not in a posion to do much about. Aston-

ishingly, a number of manufacturing employers then volunteered that at the same me

they were engaged in laying o unskilled or semi-skilled producon workers due to the

disastrous business condions, they were sll acvely searching without success to ll

long-standing openings for skilled technicians! We all then described unprecedented steps

we were taking to retain our most skilled technicians through the downturn. The conver-

saon then shied to the intermediate and long-term challenges surrounding the expected

acute shortage of skilled workers we would again face once recovery was underway.

Within a year of the roundtable discussion, this is exactly where we found ourselves. By

the middle of 2010, U.S. manufacturing output and employment were on the rise, with the

sector serving as an engine of naonal economic recovery. In a bizarre manufacturing labor

market, we faced a growing backlog of unlled openings for skilled manufacturing posions

while millions of out-of-work American workers lacked the necessary skills or preparaon

for these aracve opportunies. Worse, very few displaced workers or interested new

entrants to manufacturing were enrolled in eecve training and educaon programs to

close the gap between what they had to oer and what employers need. This heart-break-

ing misalignment remains largely our reality today.

Structural Realities Contributing to

the Skills Gap in Advanced Manufacturing

There are many factors contribung to the skills gap in the U.S. manufacturing sector, and

these factors may vary by state and by region. However, my discussions with manufactur-

ing leaders and workforce and economic professionals across the country conrm that our

experience in Pennsylvania fairly illustrates why the manufacturing skills gap is a serious

naonal problem.

While Pennsylvania’s economy has evolved and diversied away from our iconic 20th

century “smokestack” legacy of steel-making and other heavy industry, our modern

manufacturing sector sll provides direct employment to more than half a million

Pennsylvanians (PA L&I). Unknown to many, manufacturing remains the largest single

sector of Pennsylvania’s economy as measured by Gross State Product (GSP). Perhaps even

17

Manufacturing Workforce Development Playbook

more important from a workforce and economic development perspecve, our vibrant

manufacturing sector provides outsized support for employment and growth in other

economic sectors. (Pennsylvania’s True Commonwealth: The State of Manufacturing—

Challenges and Opportunies, Hill et-al. 2011, p.1 hp://urban.csuohio.edu/publicaons/

center/center_for_economic_development/Pennsylvanias_True_Commonwealth.pdf).

Recognizing the importance of the skills shortages faced by manufacturers, L&l

established the Pennsylvania Center for Advanced Manufacturing Careers (PCAMC) in 2009

under the auspices of the Steel Valley Authority (a supporter of this Playbook). I was invited

to direct the PCAMC and its outreach and research acvies. The center subsequently

idened three key structural workforce realies that threaten the ability of manufacturing

employers to realize our full potenal as drivers of regional economic vitality (Crical

Shortages of Precision Machining and Industrial Maintenance Occupaons in Pennsylvania’s

Manufacturing Sector, PCAMC, 2010, p. 1 hp://www.paworkforce.state.pa.us/portal/

server.pt/community/l_i_advisory_council_on_advanced_manufacturing/18909 ). These

realies are:

a. Rising skill requirements for entry and growth in manufacturing careers.

b. An aging manufacturing workforce, parcularly in skilled technical occupaons.

c. The lack of an adequate and reliable training and educaon pipeline for talented new

entrants into manufacturing careers.

While the needs of manufacturing employers for technical talent vary from rm to rm,

there are readily idenable skilled technical occupaons that are chronically in short

supply, specically industrial maintenance/mechatronics and precision machining occupa-

ons. An appropriate supply of talented workers in these occupaons would enable U.S.

manufacturers to maximize crical investments in technology that allow them to compete

internaonally. In 2010, the center reported that Pennsylvania’s manufacturing sector

employed 72,000 skilled technicians in these high-paying occupaons, accounng for one

of every eight manufacturing jobs. The center went on to project that the state’s manufac-

turing employers would need to ll well over 15,000 job openings in these career paths by

2020 (PCAMC, 2010, p. 4). My experience since returning to the private sector in 2011 and

my ongoing conversaons with other employers and economic and workforce development

professionals have conrmed that these projecons are essenally accurate.

In addion to these relavely measurable shortages of skilled technicians, we too oen

nd that the larger populaon of less-skilled producon workers struggle to adapt to a

rapidly changing 21st century manufacturing environment. While we readily assist our

employees in acquiring valued intermediate manufacturing skills in areas such as quality

systems, process improvement, stascal measurement, blueprint reading, and basic pre-

venve maintenance, too many producon workers (both employed and unemployed) nev-

er acquire the necessary lifelong learning foundaon to take advantage of available training

opportunies. The reasons for this unfortunate reality are long-standing and complex;

however, as employers, we simply are not well-posioned or resourced to take on the

18

Chapter One

challenges brought on by substandard academic preparaon. I have seen that a lack of

prociency in applied math skills is the most common barrier; however, low-level reading

skills and a lack of familiarity with computer technology are also oen barriers to hiring

and training opportunies. Finally, a lack of crical “so skills” such as communicaons,

teamwork, reliability, and problem-solving disqualify others from hiring and promoon op-

portunies. As a result of these barriers, many less-skilled producon workers or potenal

entrants nd themselves stuck in relavely dead-end jobs or experiencing long-term unem-

ployment, while posions requiring higher-level skills go unlled.

Modern U.S. manufacturing companies can produce substanally more output than

ever before with fewer workers and must connue to do so in an increasingly compeve

internaonal economy. This success has contributed to the well-publicized decline over

the past two decades of manufacturing employment, both in absolute numbers as well as a

percentage of the overall workforce. These well-documented changes have had a parcu-

larly devastang impact on low-skilled manufacturing workers.

Successful U.S. manufacturers have navigated the turbulence of the last two decades

by retaining their most experienced, skilled, and producve workers. Employers hold on

to these talented workers to help implement process improvements and new manu-

facturing technology to grow and compete internaonally. As a result, we now have a

more-skilled but aging workforce. The center determined that a third of skilled industrial

maintenance/mechatronics and precision machining workers in Pennsylvania’s manufac-

turing sector may rere by 2020 (PCAMC, 2010, p. 4). Manufacturing employers around

the naon report facing similar demographic realies. Given U.S. manufacturing’s conn-

ued focus on producvity improvement, I am skepcal of recent predicons from some

experts that our sector will see signicant employment growth in the future. However,

even if overall U.S. manufacturing employment levels remain relavely stable, the inevita-

ble approaching wave of skilled-worker rerements will cause headaches for employers

and tremendous hiring and promoon opportunies for replacement workers with the

proper skills, educaon, and preparaon.

Besides rising skill requirements and an aging workforce, the third structural workforce real-

ity that puts us at risk is the lack of an adequate and reliable training and educaon pipeline

for talented new entrants into manufacturing careers. In many ways, we U.S. manufacturing

employers contributed to this reality. Unlike our competors in exporng powerhouses like

Germany and Switzerland, for many years we failed to broadly and consistently engage with

high-quality technical educaon, internship/co-op, and apprenceship programs. Without

ongoing industry engagement, exisng programs too oen atrophied, failing to meet the

changing technology requirements for emerging occupaons or being forced to accept poorly

qualied candidates just to ll seats. Many other programs shut down completely as talented

youth were steered onto other career and educaon paths. The center was able to quanfy

what employers already know: The number of candidates currently compleng high-quality

manufacturing technology training programs is a mere trickle compared to current and future

needs (PCAMC, 2010, p. 5).

We cannot underesmate the erroneous but persistent public percepon that any four-

19

Manufacturing Workforce Development Playbook

year degree is preferable to technical training for “middle-skill” manufacturing jobs. (More

on that later.) This imbalance provides tremendous opportunies for new graduates, as can

best be seen in well-dened precision machining occupaons. Graduates of high school

career and technical educaon (CTE) programs in precision machining throughout Penn-

sylvania usually earn industry-recognized Naonal Instute for Metalworking Skills (NIMS)

credenals and are oen working in their career eld even before high school graduaon.

These bright young men (unfortunately, few current precision machining graduates are

women) oen receive tuion reimbursement or similar direct nancial support from their

employers if they choose to enroll in associate degree or apprenceship programs. Unfor-

tunately, a similar network of credenals and internships does not yet exist for the other

crical manufacturing occupaons in industrial maintenance and mechatronics.

Realizing the need to reverse course, many advanced manufacturing employers have

joined regional educaon and training partnerships to try to rebuild the necessary talent

pipeline. In these eorts, we have found willing partners among workforce development

professionals and some farsighted educators. Unfortunately, despite the proven

employer demand, many iniaves resulng from these partnerships sll struggle to

enroll an adequate number of candidates who are well-posioned to take advantage of

these excellent opportunies.

The Larger Challenge: Outdated Perceptions vs.

Real Opportunity in Manufacturing Careers

While the structural problems I have described are signicant, perhaps the biggest chal-

lenge we face in nding talented new entrants into manufacturing career paths is the

outdated and false impression that our sector is dirty, dull, dangerous, and dying.

On the contrary, like most modern manufacturing companies, our facilies are clean,

well-lit, safe, and home to world-class technology and equipment. When I speak with

career seekers interested in manufacturing employment, I recommend that they focus their

search on the growing number of “advanced manufacturers” that focus on the three “P”s

of (1) innovave Products, (2) world-class manufacturing Processes and technology, and (3)

highly skilled People who are curious lifelong learners.

These days, most Americans have lile exposure to the advanced manufacturing sector,

and young people exit high school with no knowledge of the aracve career paths the

sector oers to those who have the proper preparaon. I believe this occurs because

parents, public school teachers, guidance counselors, and school leaders do not generally

understand the opportunies in manufacturing and fail to encourage talented young peo-

ple to fully explore their career and educaon opons while sll in high school. Few have

had the opportunity to see a 21st century manufacturing operaon, so I take advantage of

every opportunity to invite educators to visit our facilies. Inevitably, those who visit are

surprised by what they see and leave with a greater understanding that manufacturing jobs

by and large are technology jobs. My hope is that they will encourage the right students to

explore what we have to oer.

I should note that this general lack of awareness of current career opons and cost-eec-

20

Chapter One

ve preparaon strategies is not conned to skilled technical career paths in the manufac-

turing sector. Many other “gold-collar” occupaons in sectors such as energy, construc-

on, and healthcare oer excellent career paths that combine high-quality technical skills

with solid postsecondary academics, oen leading to technology-related associate degrees.

In fact, the skills required for success in these occupaons oen can lead to employment in

various sectors.

At the root of the problem is a deeply held arcle of faith in our society that a four-year

college degree, regardless of eld of study or actual employer demand, is the one way to

career success. As a result, too many ill-advised young people are steered toward such

degrees in and aer high school. The great tragedy is that many young people on this path

do not persist to degree compleon and end up with heavy debt and few skills to oer em-

ployers. Of similar concern, many college graduates in recent years have found themselves

taking dead-end jobs without career paths that don’t pay enough to repay their student

loans or allow them to live independently.

There is an aracve and realisc alternave. Technical career paths can follow a

“2+2+2” strategy that marries technical skills acquision with academic achievement. Such

paths start with the nal two years of high school spent in a rigorous CTE program of study.

Besides imparng valuable technical skills, such programs can provide the relevance neces-

sary to movate students to high levels of academic achievement, parcularly in math and

science. More and more, rigorous CTE programs provide students with the added bonus

of earning college credits while sll in high school that can be applied to related two-year

and four-year postsecondary degree programs. Since graduates of such programs already

have a sense of career direcon and skills that employers seek, these young learners can

oen nd aracve employment opportunies and become earners while they connue

their educaon beyond high school. Even beer, we manufacturing employers realize that

it’s in our best interest to support talented and movated employees nancially as they

pursue their educaonal goals through tuion reimbursement programs, pay-for-skills-

and-knowledge pracces (including apprenceships), etc. Two-year degree programs now

more frequently allow for extensive credit arculaon toward four-year degrees in related

elds (the nal “2” in the 2+2+2 strategy). Imagine the career and life opportunies that

present themselves to a college graduate (two-year or four-year) in his or her mid-20s

with industry-recognized credenals, current manufacturing technology skills, ve years of

industry experience, and savings in the bank instead of a mountain of student loan debt!

A nal major breakdown has been our inability to eecvely connect our many

military veterans with career and educaon opportunies in advanced manufacturing.

Through rsthand experience, I know that the movaon, operaonal experience, and

learning skills of many veterans are an excellent match for a modern manufacturing work

environment. Veterans who are available and prepared to succeed in manufacturing

careers are not easy to nd, but we have had some notable success in the last two years

at both of our facilies. Here again, veterans and the well-intenoned organizaons

aempng to help veterans reintegrate into civilian life too oen lack knowledge of these

opportunies and how to connect with relevant manufacturing training programs that

21

Manufacturing Workforce Development Playbook

can speed the transion.

The hard lessons of the great recession and our naon’s subsequent slow and painful re-

covery have made many young people and their families open to careers in manufacturing.

Our challenge is to organize all interested pares and implement eecve outreach and

communicaons strategies to get the word out to educators, students, parents, veterans,

and public policy makers.

A Playbook for Closing the Manufacturing Skills Gap

Our opportunity is that a potenal workforce exists to ll the good-paying and rewarding

careers within the modern manufacturing enterprises so crical to our regional economies.

Best-pracce programs have been developed, parcularly by our community colleges, that

oer high-quality manufacturing training to help bridge the gap between potenal candi-

dates and the skill needs of employers. Unfortunately, many of these programs are not

well-aligned with secondary educaon or other feeder programs and are oen unknown to

the general public.

Individual manufacturing employers simply cannot and will not be able to go it alone in

developing the pool of skilled talent they need to grow and prosper. This is parcularly true

for the many small and medium-size manufacturers that create many of the best oppor-

tunies. I have learned that workforce and economic development professionals, labor

representaves, secondary and postsecondary educators, and manufacturing employers

are more ready than ever to do their part. What we need now is a Playbook based on prov-

en best pracces from a broad spectrum of experts. Fortunately for us, such a Playbook

is found in the pages that follow. If we follow this Playbook, then my opmisc predicon

that now is a great me to begin a career in U.S. manufacturing will prove to be reality for

manufacturing employers and talented new hires alike.

22

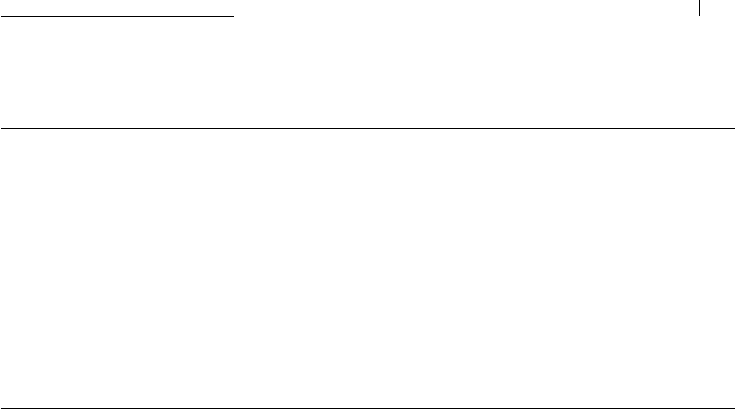

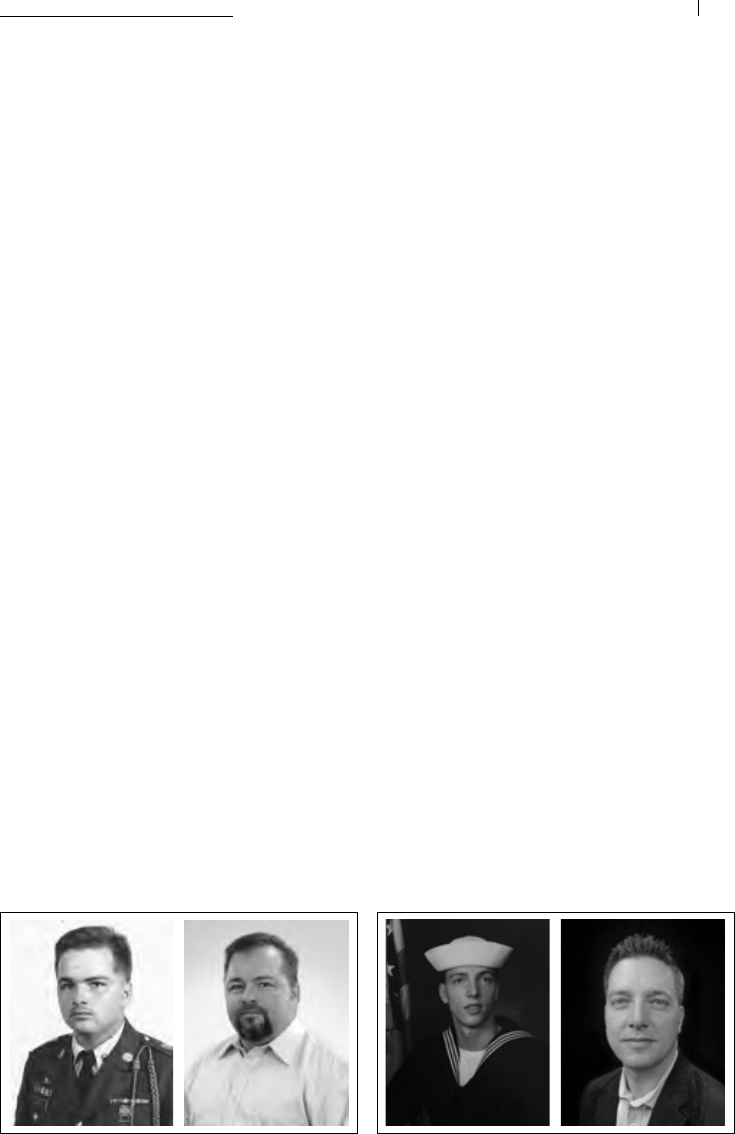

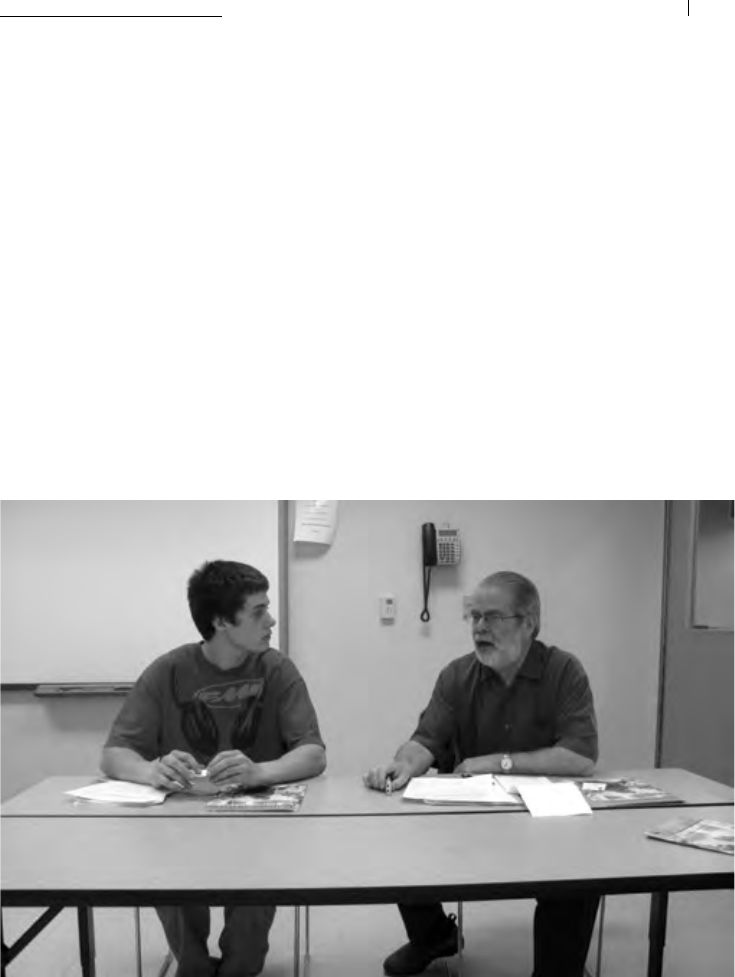

Keith S. Campbell,

Principal, Campbell

Management Services LLC;

Formerly Director Automation,

The Hershey Co.

We tend to speak of manufacturing as though it is one thing. It’s not.

Therefore, when we try to apply just one solution, that solution frequently

misses the mark. Educators think they’ve done their part by offering a

manufacturing program and that manufacturers aren’t willing to train their

employees. Manufacturers think that educators aren’t listening to their

needs and back away from participation. The alternative is to customize

everything, which becomes impractical. Manufacturers, educators,

and government must recognize the characteristics that various

segments of manufacturing share in common and leverage those to

provide a limited variety of high-quality solutions.

Chapter Two

Please see bio of this author

at the back of this Playbook

23

Manufacturing Workforce Development Playbook

Chapter Two

M

anufacturing is complicated. So much so that educators over-simplify to survive

while companies over-complicate, thinking that they each need a unique soluon.

Both are formulas for failure. We can’t expect educators to customize programs for each of

the thousands of types of manufacturing; and we can’t expect manufacturers to be sas-

ed with ‘universal’ manufacturing training, educaon, and cercaon soluons.

Somemes the people represenng manufacturers don’t themselves understand why

their employees or potenal employees need the parcular skills that they use on the job.

Students don’t understand how what they are studying relates to a parcular industry. Ed-

ucators don’t understand how dierent manufacturing sectors use technology dierently.

One electrical maintenance employee reported to me that she had an associate degree

in electronics and didn’t understand why she struggled so much with her job in a confec-

onery plant. Only when she had the opportunity to complete an industrial maintenance

program aimed at the hybrid manufacturing sector did she report that she used her training

every day on the job. Job performance and job sasfacon improved so much that she

introduced her teenage son to the same program.

I frequently nd that the manufacturing HR people who are working with educators

don’t understand why their needs are dierent from the needs of the company down the

street—or why they may be the same. As a result, they devote too much eort trying to

customize a program to their “special” needs. Language is also a problem. Too oen,

schools get requests from manufacturers for things like “electronics” when they may

mean “instrumentaon” or they may mean “PLCs.” Schools respond with “electron-

ics” classes, which to them may mean semiconductor theory. This is partly an issue of

specifying classes or curriculum rather than specic competencies and skills. Later in this

book, we will learn more about competencies vs. curriculum. For now, let’s try to under-

stand how to simplify, but not oversimplify, manufacturing to make it easier for educators

and industry to work together.

Manufacturing is not well understood

Many Americans have dismissed manufacturing as a dying industry, and as a result, they

by Keith S. Campbell

Manufacturing is Complicated

There are no one-size-fits-all solutions to the

workforce development challenge, but we needn’t

customize everything either.

24

don’t spend much me trying to understand it. We might all agree that manufacturing

somehow involves making stu—but then we might get into some extended debate about

the meanings of the words “making” and “stu.” An illustraon of this point is a manufac-

turers’ associaon meeng where a colleague and I were invited to speak on the topic of

industrial maintenance and mechatronics. Before the meeng, I inquired of the aendees

what kind of manufacturing they were involved in. Almost all were from the discrete sec-

tor, and the program that I was prepared to discuss was targeted at hybrid manufacturers.

I asked the host if they didn’t have food, beverage, pharmaceucal, or similar consumer

products companies in the area. The answer was that they did, but their group didn’t con-

sider them as “manufacturers,” and they hadn’t been invited.

If those of us inmately involved with manufacturing have problems with our vocabulary

and understanding what we mean when we speak about manufacturing, how much more

dicult must it be for the general public?

Someone once described manufacturing to me this way: “It is something that takes place

inside a windowless building located behind a dike that you can only pass through with the

guard’s approval.” When I grew up, summer vacaons involved stopping to tour manufac-

turing plants; in Europe, major trade fairs sll include family days where parents can walk

through with youngsters in strollers to see all of the latest machinery innovaons. But in

America today, most plants are closed to the public, and trade fairs admit no one under the

age of 16. Our schools neither promote manufacturing as a career nor educate students in

the necessary technical skills, preferring instead to push everyone toward a college degree

in an economic society where less than one-third of jobs require a four-year degree and

where only 56% of four-year college students nish within six years. Is it any wonder that

Chapter Two

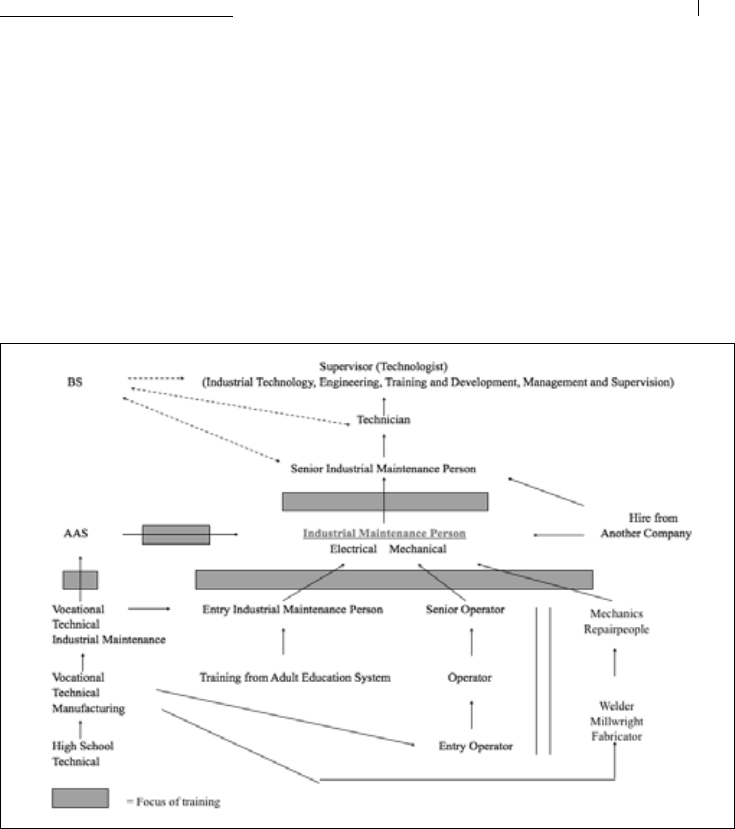

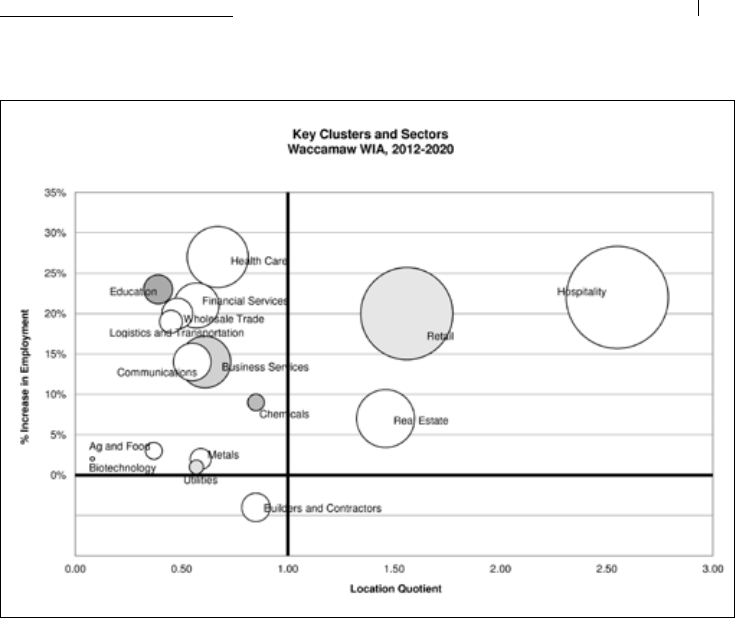

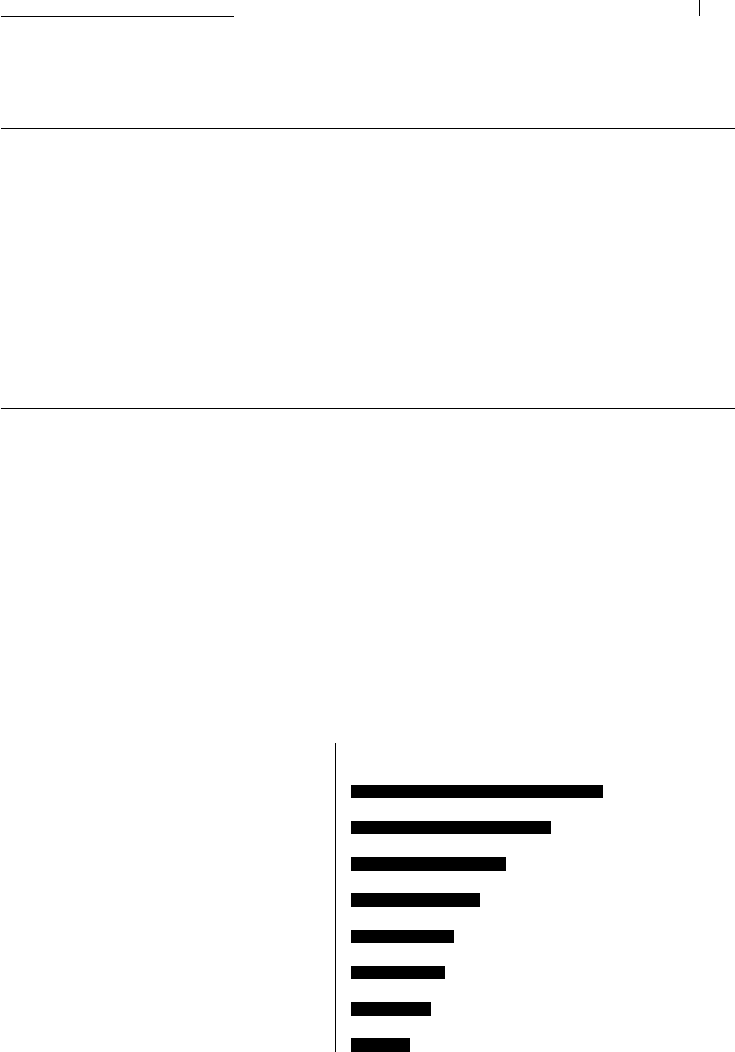

Figure 1.

25

Manufacturing Workforce Development Playbook

we have become so uninformed about and unprepared for manufacturing?

Manufacturing is broad in scope

In seeking clarity, I set out to nd out how the government denes manufacturing. This led

to the Census Bureau and the North American Industrial Classicaon System, known as

NAICS codes. The Census Bureau says, “The manufacturing sector comprises establish-

ments engaged in the mechanical, physical, or chemical transformaon of materials,

substances or components into new products. The boundaries of manufacturing and

the other sectors of the classicaon system can be somewhat blurry ....” The NAICS

codes for manufacturing at the six-digit level run from 310000 to 339999 within which

there are 10,537 types of manufacturers idened.

So, are we to understand manufacturing as one thing or as 10,000 dierent things?

When we seek training, educaon, and cercaon programs, should there be one

standard for manufacturing, or should there be mulple standards? Clearly a custom solu-

on—one for each type of manufacturing, or one for each manufacturer, or one for each

plant within a manufacturer’s company—is NOT a workable soluon. And manufacturing is

indeed too complicated for one-size-ts-all soluons, which are really lowest-common-de-

nominator answers that sasfy no one and will not make us compeve in today’s increas-

ingly complex and technically advanced world. Is there a useful soluon?

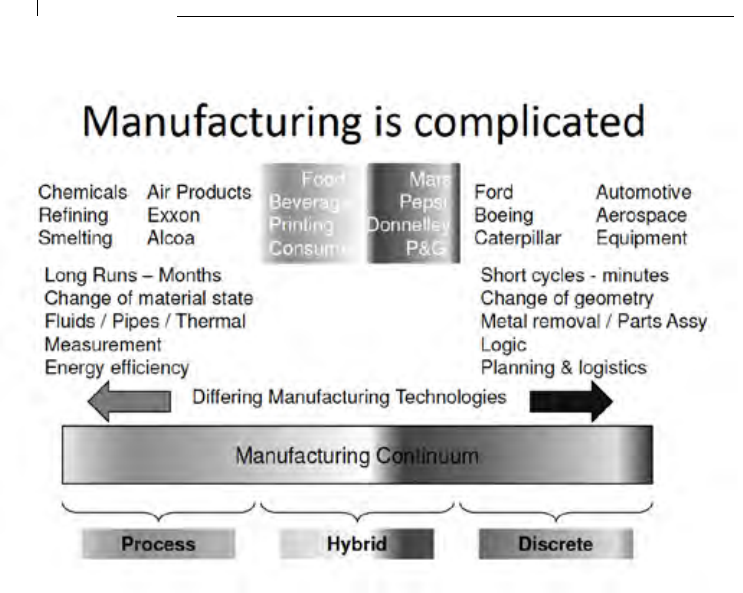

A useful subdivision

A useful way of viewing manufacturing is along a connuum, which may in fact include

10,537 dierent types. Manufacturers are placed along the connuum based upon

some chosen set of aributes, and the connuum is then divided into a limited number

of named sectors. In my simplied model, there are three sectors idened as Process

Manufacturing at one end, Discrete Manufacturing at the opposite end, and Hybrid Man-

ufacturing in the middle (Figure 1).

Process Manufacturing

The prototypical process manufacturer will operate with long runs that could extend 24

hours per day seven days per week with just one startup and shutdown per year. There

will oen be a change of chemical state of the material in a vessel or reactor, and the

material may be capve within pipes or other means of conveyance. Control will be of

a connuous nature and depend upon measurements of physical properes such as

temperature, ow rate, density, and chemical composion. Process control is frequently

hierarchical and distributed with large operator interface systems in centralized control

rooms that display operaons that may be miles away. Systems may be redundant with

automac failover to backup processers and locaons. Control may be based upon

mathemacal algorithms using feedback, cascade, and feedforward strategies. Money is

made or lost in the plant based upon fraconal improvements in operang quality and

energy eciency. Operators may be degreed engineers who are supported by techni-

cians and trades people who operate across some extended geography. Plant design is

less about individual machines and more about unit operaons that are congured from

26

components like valves, tanks, and pumps. The design is frequently done by or closely su-

pervised by an internal engineering sta, resulng in design details, soware, schemacs,

and other documentaon fully in control of the plant and available to the maintenance

technicians who may be expected to alter any of it under appropriate supervision. Basic

plant design changes infrequently (years or decades), while improvements may be con-

stant. Think about bulk chemicals, rening, or smelng operaons that might be done by

companies such as Air Products, Exxon-Mobil, or Alcoa.

Discrete Manufacturing

The prototypical discrete manufacturer will operate with short cycles that might be mea-

sured in minutes. An operaon may turn out many idencal but individual parts during

the course of a shi, or there could be very frequent changeovers to diering parts with

order quanes as small as one discrete unit. There will be changes of geometry involved

through material removal, material addion, bending, or assembly. Control will be largely

of a sequenal nature using logical operaons based upon sensors that feed back posion

and other physical aributes. Machines will oen employ electrohydraulic systems, ded-

icated CNC, robot controllers that coordinate half a dozen moon axes, and the PLCs that

oversee sequenal operaons and the interlocking between adjacent operaons. With fre-

quent changeovers the rule, the primary operator interfaces tend to be local to individual

machines. Money is made or lost based upon planning and logiscs, geng the right things

to the right place at the right me and keeping everything running. Operators load and

unload machines, adjust parameters, assemble components, and compare results to draw-

ings by making physical measurements. Plants, or the ow of materials through plants,

are frequently recongured (months). The basic machines and workcells are designed by

others, who may maintain control of the soware and detail documentaon, rendering it

unavailable to the plant’s maintenance sta. With a large variety of machines in use, rou-

ne maintenance may be done internally with troubleshoong and repair frequently done

by equipment manufacturers. Think about machined parts, aircra assembly, electronic

equipment, or automobiles that might be made by small machine shops, Caterpillar, Boe-

ing, Dell, or Ford.

Hybrid Manufacturing

The prototypical hybrid manufacturer will have connuous or batch-connuous operaons

that start o looking much like small-scale process manufacturing and end up looking more

like discrete but connuous manufacturing requiring an intermediate level of change-

over. Raw materials may be connuously blended and cooked, resulng in some chemical

change. Then they proceed through a forming stage, where changes to the physical

geometry may be made, and then on to packaging, where individual pieces are inspected,

wrapped, and assembled into larger units with similar or dissimilar components. Control is

oen a mix of analog feedback control and sequenal logic systems ghtly integrated with

general-purpose moon control and roboc cells. Systems with 100 servo axes coordi-

nated over large distances may be common, resulng in operator workstaons on the

Chapter Two

27

Manufacturing Workforce Development Playbook

oor that interact with mulple unit operaons and machines that are spread over some

distance. Money is made by balancing producon eciency and logiscs resulng in mass

customizaon. Plant design changes at an intermediate frequency (years) and may be

accomplished by a combinaon of internal and external resources; but because of ghtly

integrated operaons, machine soware and other documentaon is oen available to

maintenance personnel, who will be expected to troubleshoot and repair all but the most

dicult and infrequent failures. Think about food, beverages, prinng, or consumer prod-

ucts made by companies such as Mars, Pepsi, Donnelley, or Procter & Gamble.

The Economics

This classicaon of manufacturers may seem a bit arbitrary, and various excepons will be

plenful to the prototypical descripons oered above. But throughout my career, I have

found this segmentaon to be both meaningful and useful. Some validaon is provided by

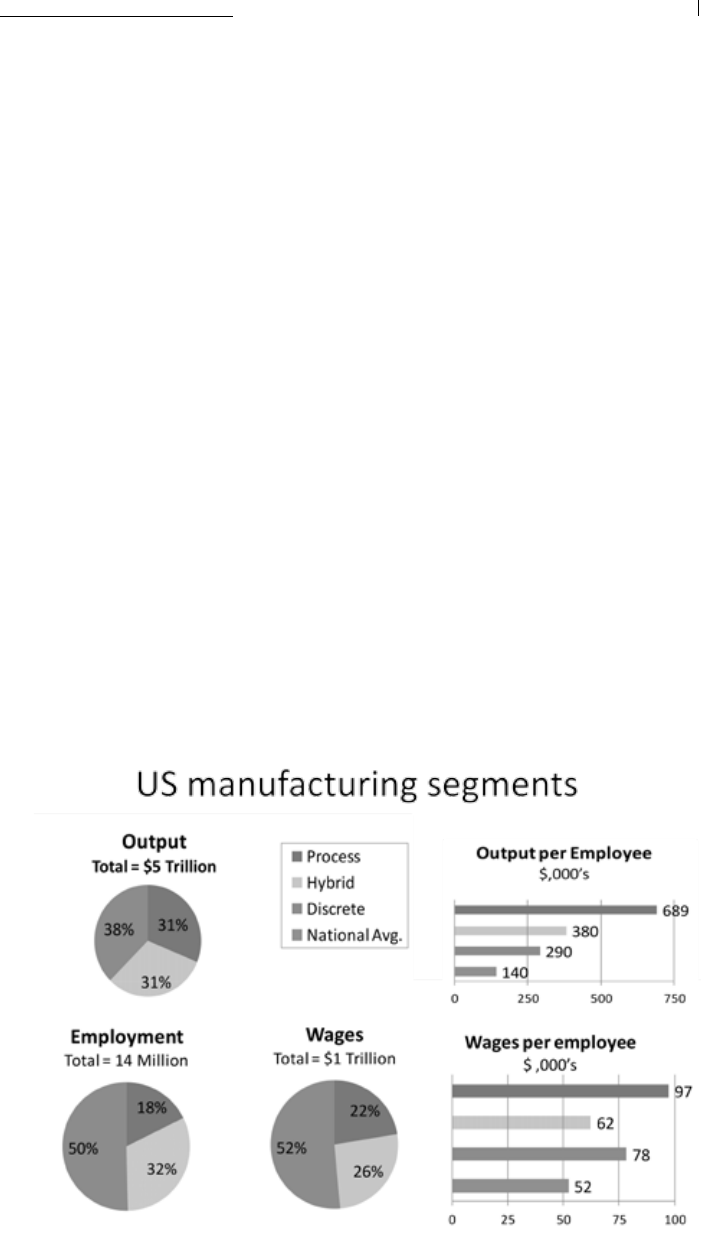

looking at the economic numbers when manufacturing is segmented in this way (See Figure

2). Total U.S. manufacturing output is approximately $5 trillion. By sector, process and hybrid

each account for 31% of this output, with discrete claiming a slightly larger 38%. Manufac-

turing employment is 14 million persons, but the division by sector is quite dierent than by

output. Discrete manufacturing claims 50% of the employment, with hybrid accounng for

32% and process only 18%. Total wages of $1 trillion are also skewed, with discrete account-

ing for more than half of the wage base at 52%, hybrid 26%, and process 22%.

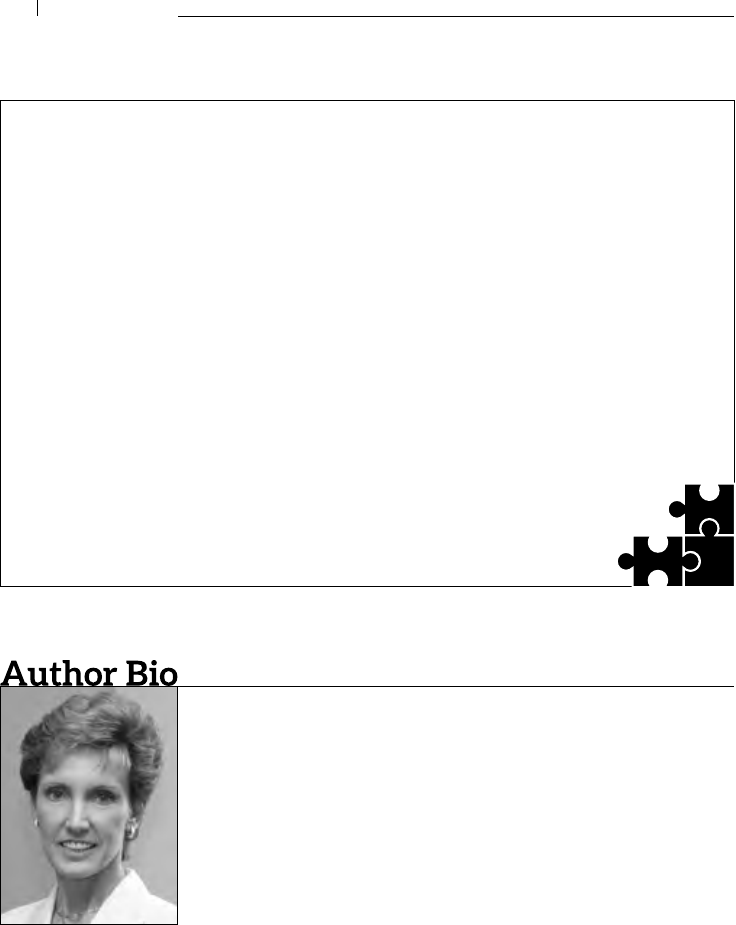

From this basic data, we can see some important facts that make intuive sense. First,

output per employee, or producvity, is much higher in the process industries, exceeding

Figure 2.

28

discrete producvity by almost 2 1/2 mes. Second, process employees, at $97,000, have

the highest wages per employee. If we think about large process plants with control rooms

full of distributed control systems operated by employees with some college, or maybe

even a degree, this data makes sense.

Discrete manufacturing has the lowest producvity, yet the second highest wages per

employee. This could be because of higher skill requirements or more changeover issues in

the discrete world, or it could be a reecon of the wages that are being paid in industries

that are more highly unionized. In any case, there would seem to be some signicant op-

portunity for discrete manufacturers to improve their producvity numbers.

Hybrid manufacturers pay the lowest wages and have producvity midway between pro-

cess and discrete. Many process plants went fully automated in the last quarter of the 20th

century. There are certainly opportunies for connuous improvement in process plants,

but many hybrid plants have not yet taken advantage of the opportunies available with

new mechatronic soluons, process control, and batch automaon. Real opportunies for

applying advanced manufacturing automaon techniques, and for worker upskilling, exist

in hybrid manufacturing, leading to higher prots for owners and lifestyle improvements for

workers. The dierence in wages and producvity alone are enough to aect the educa-

on and training expectaons of manufacturers from these three sectors.

An overarching fact not to be overlooked in this data is that manufacturing wages per

employee are 50% higher than average wages overall in the economy, and manufacturing

producvity is 2 1/2 mes the naonal average. The least producve manufacturing sector

is more than twice as producve as the economy as a whole.

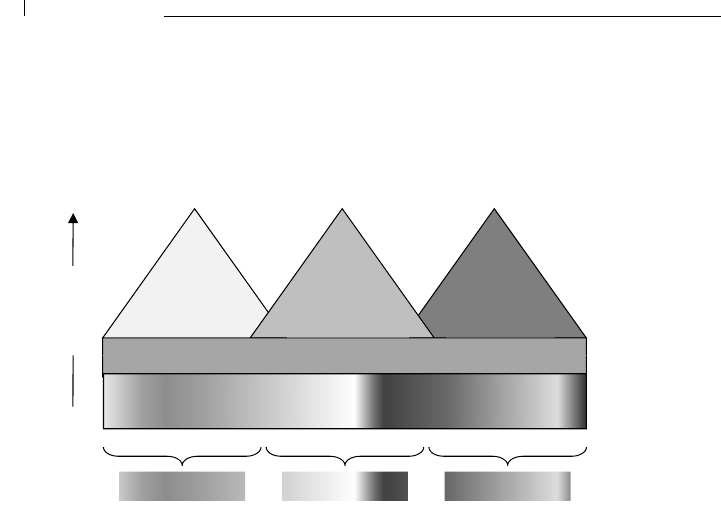

Models are meant to be useful, not perfect

This model is meant to simplify, not to be all-inclusive. It provides rules of thumb, and rules

are meant to be broken. For example, some companies may have both process and discrete

Advanced Industrial Maintenance Skills Vary

Hydraulics

HydraulicsHydraulics

HydraulicsPneumatics

PneumaticsPneumatics

Pneumatics

Common core skills

–

math, electricity, mechanics, motors

Skill Level

Proportional

Proportional Proportional

Proportional

Valves

ValvesValves

Valves

Cascade

Cascade Cascade

Cascade

Control

ControlControl

Control

Coordinated

Coordinated Coordinated

Coordinated

Multi

MultiMulti

Multi-

--

-axis

axis axis

axis

Motion

Motion Motion

Motion

Control

ControlControl

Control

CNC

CNC CNC

CNC

Control

ControlControl

Control

Common core skills

–

math, electricity, mechanics, motors

Manufacturing Continuum

Process DiscreteHybrid

Chapter Two

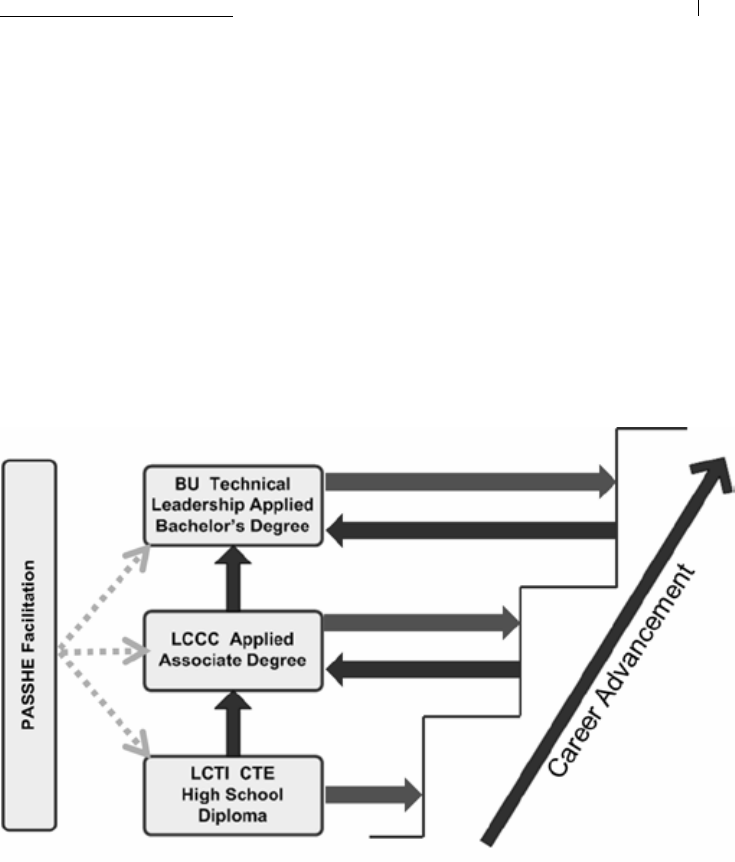

Figure 3.

29

Manufacturing Workforce Development Playbook

operaons within the same plant and not be considered a hybrid. And there may be blurring

at the edges between manufacturing and non-manufacturing. For example, ulies, mining,

and agriculture will share some aributes with the various manufacturing sectors. A training

program for an electric ulity or a pipeline may look a lot like that for a chemical plant. A

farmer using geospaal mapping and soil sensors to batch the proper amount of ferlizer to

a eld using mechatronic systems in a tractor may have needs similar to a hybrid manufac-

turer, as will a supply chain technician in an automated fulllment warehouse.

The purpose of a model is to be useful. We know that Newton’s formula F=ma does

not explain everything correctly, but in many circumstances it is sll useful. The asseron

here is that this three-sector model is useful when developing manufacturing workforce

training, educaon, and cercaon programs. It may be applied to the unique skill

needs of operators, maintenance technicians, and supervisors.

Manufacturing sectors affect workforce development plans

Customizing training, educaon, workforce development, and cercaon plans by manu-

facturing sector is a workable strategy that will increase the sasfacon of industry and the

acceptance and penetraon of educators as we work together to solve the workforce crisis

in America (See Figure 3). It will eliminate the need for educators to create a customized

program for every plant or company. It will facilitate the use of industry-recognized creden-

als by eliminang the need for every kind of manufacturer to nd or develop their own. It

will allow companies to achieve the crical mass necessary to inuence local and naonal

decisions about educaon and workforce development. Recognizing that a small food com-

pany, a large automated warehouse, and a ferlizer plant share similar competency needs

for their workers will allow them to collecvely approach their workforce agency and local

high school technology center or community college to develop higher-quality programs that

meet the needs of a wider customer base for the educaon provider. That is not to say that

schools shouldn’t make customized training for individual employers. But it is to suggest that

if they start with the right plan for the sector, the customizaon should be minor.

Leveraging manufacturing sectors

As a manufacturer, your operaons may be unique, or they may be only like those of your

competors with whom you don’t wish to collaborate. But the underlying technologies and

aributes of your process, hybrid, or discrete sector have you sharing much in common

with other manufacturing companies in that same sector. Leverage your sector to inuence

automaon vendors, educators, soware providers, and others.

As a provider of products or services to manufacturers, don’t assume that one size will

t all. Idenfy the sectors of your customers, and start out by tesng the hypothesis that a

soluon customized for a parcular customer’s sector will meet most of the needs of any

customer within that sector.

Once both manufacturers and suppliers recognize and simplify manufacturing by sector,

the task of developing plans, strategies, and winning soluons will become less challenging

and the results more useful.

30

A

s I was winding down my involvement as Execuve Director of the OMAC

Packaging Workgroup (OPW), I was invited to a regional meeng on man-

ufacturing skills development, a topic that aligned with OPW’s PackLearn

iniave. I decided to aend, only to nd that the meeng had been cancelled,

and that Sco Sheely and I had not been told. As a result, we bumped into one

another in the hallway outside the room that the meeng was to have been held in,

introduced ourselves, complained about the meeng being cancelled, and then sat

and shared ideas about the need for advanced skill development in manufacturing.

That was 10 years ago, and Sco and I have been working toward common goals

ever since.

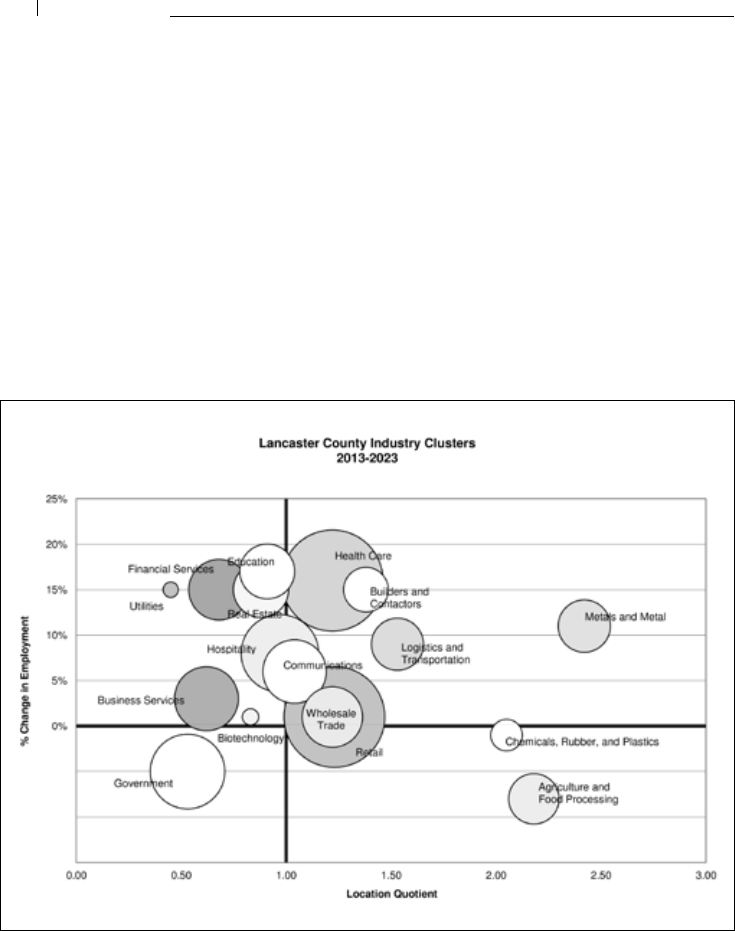

Sco J. Sheely has been the Execuve Director of the Lancaster County Workforce

Investment Board, one of 22 such boards in Pennsylvania, since 2000. Vocaonal-

ly, he has worked as the human resources director of a large mental health agency,

the operaons manager of a nursing home chain, the associate pastor of a church,

and the owner of a regional wholesale jewelry business. A graduate of Franklin and

Marshall College in government, Wright State University in mental health counseling,

and United Theological Seminary in pastoral counseling, Sco is currently a doctoral

candidate in adult and workforce educaon at Penn State University.

With many partners, he is the founder of the Food Manufacturers’ Training Con-

sorum of Southcentral PA, the Industrial Maintenance Training Center of Pennsyl-

vania, and the Mid-Atlanc Mechatronics Advisory Commiee. Sco was the chief

architect of the Mechatronics Competency Model that was adopted by the U.S.

Department of Labor. He works closely with PMMI as that organizaon builds out

the components of its mechatronics industry credenal.

Scott J. Sheely,

Executive Director,

Lancaster County

Workforce Investment

Board

Workers arrive at a manufacturing job having traveled many different routes.

Just as the previous chapter points out that there may be different prepa-

ration required depending upon the manufacturing segment one works in,

this chapter points out that the characteristics of that preparation may need

to vary depending upon the path being taken to that career. Although the

knowledge and skills obtained may be the same in the end, the strategies

for obtaining the knowledge and skills may vary widely for a full-time high

school student, a returning-to-the-workforce mother, a veteran, the long-

term unemployed, an incumbent worker, or an ex-offender. Under-

standing the pathways issue is essential to creating the programs

that meet the most needs. While an “all of the above” approach

might be desirable, it is not the place to begin.

Chapter Three

31

Manufacturing Workforce Development Playbook

O

ver the last several years, career pathways have become increasingly popular frame-

works for talking about the variety of career opons that are available to people who

are preparing to enter the job market or looking for work aer an employment dislocaon.

They use occupaons as a kind of roadmap for job seekers, and many have been organized

in “ladders” or “laces” showing occupaonal progression.

Characteristics of Pathways

Pathways are nearly always referred to in the plural. Any one job has mulple ways that

people nd the knowledge and skills to perform it. In the same way, any pathway oen

leads to many jobs that make use of the knowledge and skills acquired.

Extending the pathway metaphor, these theorecal constructs also help us understand

the “on-ramps” and “o-ramps” as people move through the lifelong learning that is

required to proceed along the pathway. Veterans, dislocated workers, new workers, ex-of-

fenders, and others will bring dierent knowledge and skills to the pathway at parcular

mes in their careers. As the pathway model is applied, it needs to account for these

dierent talents that the learner brings and allow them to move ahead with addional

knowledge and skill acquision.

If done most eecvely, career pathways must also reect the needs of employers and

recognize the reality of the way people progress through levels of the work environment.

They are just as important for incumbent workers as for entering workers, parcularly at a

me when employers in the U.S. (and around the globe) are dealing with the talent short-

age that will develop as the Baby Boomer generaon changes its relaonship to work over

the next several decades.

Industries like manufacturing and construcon that rely more on on-the-job training rath-

er than those such as healthcare, which require more academic credenals and licensing,

will have very dierent pathways.

As we look at all forms of educaon today, it is clear that formal educaon is more valued

than hands-on or tacit educaon…the kind that comes from sing next to and observ-

ing a journeyperson welder, mechanic, installer, or operator. Tacit educaon, along with

Chapter Three

by Scott J. Sheely

Manufacturing Career Pathways

Where do manufacturing workers come from,

and how do they advance?

32

foundaon skills and some basic didacc knowledge, forms the basis for training many

of the middle-skill jobs that will be in short supply over the next two decades as the new

demographic-based dislocaon moves into full swing.

Identifying a Pathway

Through a process of analyzing secondary occupaon data, it is possible to idenfy pathway

concepts that can be further developed into pathway models. Typically, the researcher

examines occupaonal projecons and organizes them into categories that can be tested

for wage and skill progression. A regional economy normally contains six to eight of these

pathway models.

For example, in Lancaster County, PA, which has a very large manufacturing sector that

includes food processing, metal fabricang, prinng, and packaging, we have idened

from the occupaonal data a Producon Career Pathway that looks like this:

• Entry-level

o

Industrial Truck and Tractor Operators (Forkli Operators)

o

Hand Packers

o

Inspectors and Testers

• Intermediate-level

o

Single trades

w Machinists

w Welders

w Heavy Tractor-Trailer Drivers

w Maintenance and Repair Workers

o

Machine operators

w Prinng Press Operators

w Print Binding and Finishing Workers

w Food Batchmakers

w Packaging Machine Operators

• Upper-level

o

Industrial Machinery Mechanics

o

Mechatronics Engineering Technologists

o

Supervisors of Producon Workers

Levels show a clear wage and skill progression, and the occupaons associated with the

levels are projected to grow in the region over the next decade. This is the theorecal

pathway model.

Pathways in Practice

However, to bring the model alive for praconers, one needs to add other informaon

that needs to be collected from the industry. We invited 25 industrial maintenance super-

visors from mid-size to larger manufacturers to a focus group to tell us about the mulple

Chapter Three

33

Manufacturing Workforce Development Playbook

pathways that people use to become an Industrial Machinery Mechanic or Mechatronics

Engineering Technologist (or several other job tles commonly associated with the Industri-

al Maintenance Technician cluster of jobs).

They told us a much more nuanced story about pathways that are illustrated on the

chart below.

• We began with the assumpon that many people enter the pathway through formal

educaon, beginning with high school technical programs that arculate to postsec-

ondary training, which ow people toward jobs in the Industrial Maintenance Techni-

cian (IMT) cluster. We found that fewer than 15% of people actually enter jobs in that

cluster by this path and, from the commentary from supervisors, that many people

who do come through these educaonal programs sll need a great deal of on-the-job

training to be fully funconal.

• Supervisors spoke in a posive way about people who aain some level of technical ed-

ucaon in maintenance either at the secondary or postsecondary level, get experience

in a small to mid-size manufacturer, and come to work with a larger manufacturer with

a broader level of knowledge and experience. Hiring people from other usually smaller

companies is another way that people move along this pathway.

• Another clear trend in talent development that takes place along the pathway involves

idenfying people with maintenance knowledge and skills in the machine operator ranks

34

and oering them ways to take on maintenance tasks on the job. Many companies spoke

of making operators “machine owners,” allowing them to take on prevenve maintenance

funcons that may then lead to an invitaon to do more in the maintenance area.

• Finally, companies have been very involved in taking single trades such as welders,

millwrights, electricians, and others and adding addional skill training to make them

into the mulskilled technician that is required in industrial maintenance. Several of

the supervisors spoke about welders’ abilies to do maintenance tasks because of their

ability to think three-dimensionally, read blueprints, and fabricate.

• We also found out one other thing. When our friends in higher educaon pushed the

idea that IMTs eventually needed a bachelor’s degree, the supervisors in the room dis-

missed that noon. They admied that a bachelor’s degree might be good if mainte-

nance people become trainers or supervisors or managers; but for praconers, there

was no value added in further formal educaon.

With our interest in workforce development, we also asked the focus group to share their

opinion of where further training would be most applicable. There was near consensus

that training for higher-level skills required for the IMT cluster should build on a solid base

of experience rather than the other way around.

This insight was pivotal as the workforce and educaon system in Berks and Lancaster

Counes in Pennsylvania build out a systemac approach to skills acquision along the

Manufacturing Career Pathway.

• People already on the job (incumbent workers) become the focus of higher-level skill

training in industrial maintenance and mechatronics. A network of employers idenes

candidates who parcipate in a program of online instrucon and laboratory pracce

culminang in tesng that stresses troubleshoong skills.

• Schools and workforce organizaons prepare potenal employees to join the Manufac-

turing Career Pathway at lower levels. However, they encourage people to parcipate

in skill training (blueprint reading, hand and power tools, safety, forkli operaon) that

lays a foundaon for future training and progression down the pathway.

• Veterans are able to bring skills from their military service and nd a place along the

pathway where they can be applied.

• In a similar way, persons who have experienced a dislocaon from a job can nd ways

to use the skills that they bring and addional skills that they may acquire at various

levels along the pathway.

• Many other people, including those reentering the community from prison and those

transioning o of welfare, can learn skills that qualify them for entry into lower-level

jobs on the pathway as their “on-ramp” to beer jobs in the future.

In Summary

Career pathways allow the individual to see a plan that becomes their pathway to the

future and establish what they, as individuals, must do to move into it and along it. Career

pathways allow educators and workforce planners to target training to the areas where it is

Chapter Three

35

Manufacturing Workforce Development Playbook

needed as people move through the system. Career pathways help employers to not only

idenfy the skill training that their incumbent workforce needs, but to also evaluate the

knowledge and skills of their prospecve workforce as they hire into it.

However, to be useful, pathway models must be tested and be informed by the reality of

the work world as they are put into pracce.

36

O

ne of the most telling and comprehensive reports on the state of workforce

preparaon in America was published by the Harvard Graduate School of

Educaon in 2011. I rst saw a presentaon on the report in late 2012 at

a community college near Pisburgh. The facts presented paint a picture dierent

from the one that many Americans assume. The soluons suggested are at once

both simple in concept but challenging in execuon. Who beer to summarize this

landmark report than the Project Director, William Symonds.

Dr. Symonds helped launch the Pathways to Prosperity Project at the Harvard

Graduate School of Educaon in 2008, and he served as its director through June,

2013. He was the primary author of the seminal report issued by the project in

early 2011: Pathways to Prosperity: Meeng the Challenge of Preparing Young

Americans for the 21st Century. Since the report’s release, Bill has spoken in 40

states. He was also the principal organizer of a naonal conference held at Har-

vard in March, 2013, called, “Creang Pathways to Prosperity.” Symonds is now

working to create the Global Pathways Instute to help lead a naonal movement

aimed at preparing all young Americans to lead successful lives. He also con-

nues to speak to groups around the country about how we might help young

people build successful careers.

Prior to coming to Harvard in 2007, Symonds spent nearly 25 years as a senior

correspondent and bureau chief with Business Week magazine. During his career

at Business Week, he covered businesses in virtually every industry leading bu-

reaus in Pisburgh, Denver, and Boston, as well as in Italy and Canada. He also

served as Business Week’s chief educaon correspondent for many years.

William C. Symonds,

Formerly Project Director,

Pathways to Prosperity

Project, Harvard Graduate

School of Education

The most commonly thought of pathway to a career, and arguably the most

effective one, is a direct pathway from high school to higher education to

work. Most parents want their children to graduate from high school, go to

a prestigious university, and enjoy a good-paying career. But unfortunate-

ly, in the 21st century, this expectation is increasingly not being met. We

need to change the national dialog about higher education and recognize

that there are alternative strategies that lead to a student’s success. The

facts are staggering. The solutions were well known to American plan-

ners at the end of World War II, but rejected. We need to rethink

the school-to-work pathways if we want more students to achieve

success, if we want to revitalize manufacturing, and if we want

to give a dynamic boost to our economy.

Chapter Four

37

Manufacturing Workforce Development Playbook

Chapter Four

E

ven though the U.S. economy is connuing to recover from the Great Recession, it is clear

that we sll lag behind many naons in preparing young people to lead successful lives

as adults. Evidence of this failure is seen everywhere—from the staggering levels of youth

unemployment/underemployment to the millions of young people who drop out of high

school or college before earning a degree. This epidemic has become so pervasive that it now

touches virtually every family in America. And if we don’t develop eecve soluons to this

crisis, it threatens to undermine the future strength of our economy.

This failure has especially serious implicaons for manufacturing. One of the key reasons

so many young people are struggling to nd good jobs is the huge disconnect that’s devel-

oped between educaon and the needs of industry. Business leaders increasingly complain

that many high school and even some college graduates don’t possess the skills they need

in today’s economy. Nowhere is this “skills gap” more apparent than in manufacturing.

Indeed, as I’ve traveled to 40 states speaking about this problem over the past three years,

I’ve heard repeated complaints from manufacturers about the problems they’re facing ll-

ing skilled jobs. This issue has come up everywhere from rural New England to the Midwest

to the Pacic Northwest. And it’s clearly a big problem. A 2011 study by Deloie and the

Manufacturing Instute esmated that 600,000 manufacturing jobs were unlled because

of this skills gap, with the shortages especially acute among skilled producon workers.

A major reason we confront this predicament is that in recent years, the U.S. has put