Classic

®

Instructions for Use

IPS

2

Table of Contents

3 IPS Classic

6 Zusammensetzung

7 IPS Classic – Shade Code

10 IPS Classic – Description of the assortments

10 IPS Classic Mini Kits

11 IPS Classic Opaquer / IPS Classic V Opaquer

12 IPS Lowpaque / IPS Lowpaque V

13 IPS Margin / IPS Margin V

14 IPS Opaque Dentin / IPS Opaque Dentin V

15 IPS Classic Dentin / IPS Classic V Dentin / IPS Classic Intensive Dentin

16 IPS Classic / IPS Classic V Incisal and Transparent materials

17 IPS Effect

18 IPS Impulse

19 IPS Gingiva

20 IPS Shade / IPS Shade V

20 IPS Stains P

21 IPS Classic Glaze Paste

21 IPS Classic Correction Powder

22 IPS Classic – Liquids

24 IPS Classic – Shade Selection

25 IPS Classic – Layering diagrams

26 IPS Classic – Framework design

27 Functional support of the veneering ceramic

28 Framework design for ceramic shoulders

28 Framework strength

29 Framework design for bridges

30 Design of bridge pontics

30 Interface between metal and ceramic

31 IPS Classic – Instructions for Use

31 Starting situation

31 Fabricating the framework

31 Oxide firing

32 1

st

opaquer firing

33 2

nd

opaquer firing

34 1

st

margin shoulder firing

35 2

nd

margin shoulder firing

35 1

st

dentin and incisal firing

37 2

nd

dentin and incisal firing

38 Preparing the restoration for glaze firing

38 Stain and characterization firing

39 Glaze firing

40 Corrective firings

42 IPS Classic – Firing parameters

44 IPS Classic – Materials combination tables

44 Chromascop

45 A–D

46 IPS Classic – A sound concept always reaps success!

3

Classic

®

IPS

IPS – Ivoclar Porcelain System

A high requirement is placed on ceramic

restorations today. Therefore, every ceramist

needs a program capable of reproducing top

aesthetic results, while offering maximum

possibilities for individual skills.

The Chromascop shade guide applies for the

IPS Classic ceramic material. IPS Classic V is

based on the A–D shade guide.

The Material

New methods of production and accent on

innovation provided the impetus for

developing this IPS Classic ceramic line.

Stringent quality control of materials and a

special distribution system for particle size

give IPS Classic its several advantages. For

example, feldspar, the raw material, is sub-

jected to chemical analysis prior to selection

and checked for impurities.

Precise compounding of the components

emphasizes properties such as the coefficient

of thermal expansion, transformation range

and crystal growth. That makes it possible to

mix most the materials of IPS Classic and

IPS Classic V and process them together.

Advantages of the IPS Classic

Ceramic Line

– Clinically proven

–Efficient and economical use of the

material

– Highly aesthetic restorations

– Easy handling

– Excellent matching of shade with the

Chromascop and A–D shade guide

– Special materials for individual

characterization effects

– Opalescent incisal and effect materials

– Coordinated equipment components:

Programat

®

X1, Programat P200

– Compatible alloys

– Suitable cement Vivaglass

®

CEM

CTE – Coefficient of Thermal

Expansion

There are over two thousand alloys available

on the dental market worldwide. Because of

this large number, it is not possible to test all

these alloys with regard to their compatibility

with IPS Classic and IPS Classic V. As a result,

we are limiting our recommendations to the

respective cooling phases of the different

alloy types.

Generally, the specifications of the alloy

manufacturer must be observed. An

important factor is the coefficient of thermal

expansion (CTE) following the casting

procedure in the dental laboratory. The CTE

should be measured in the same temperature

range as that of ceramic materials. For the

CTE of IPS Classic and IPS Classic V the

temperature range is given at 25–500°C as

stipulated by EN/ISO 9693.

Generally, IPS Classic and IPS Classic V are

suitable for use with alloys with a CTE of

approx 13.7 to 15.5 x 10

-6

x K

-1

at

25–500°C. Depending on the type the

composition of the alloy, the firing

temperature and the cooling phase in

particular have to be taken into

consideration.

Alloys with a CTE in the lower range (e.g.

approx 13.7–14.5 at 25–500°C) can be

processed with standard cooling. That is, the

fired object is removed from the ceramic

furnace after the firing program with a

cooling phase in the open furnace has come

to an end. Ceramic furnaces from Ivoclar

Vivadent announce the end of the firing

program with an acoustic signal.

4

Long-term cooling depends on the type and

the CTE of the alloy used. A longer cooling

phase increases the CTE of IPS Classic and

IPS Classic V. Repeated firings have a similar

effect.

Rule of thumb: The higher the CTE of the

alloy, the longer the long-term cooling. If

long-term cooling is required, it should be

carried out after every firing procedure,

except when firing the opaquer or soldering.

Alloys

The compatibility of the following alloys and

IPS Classic and IPS Classic V have been

thoroughly tested. Additionally, they are

listed on the Ivoclar Vivadent Alloys Chart

(Dental Alloys – Compositions and physical

properties).

The product range may vary from country to country.

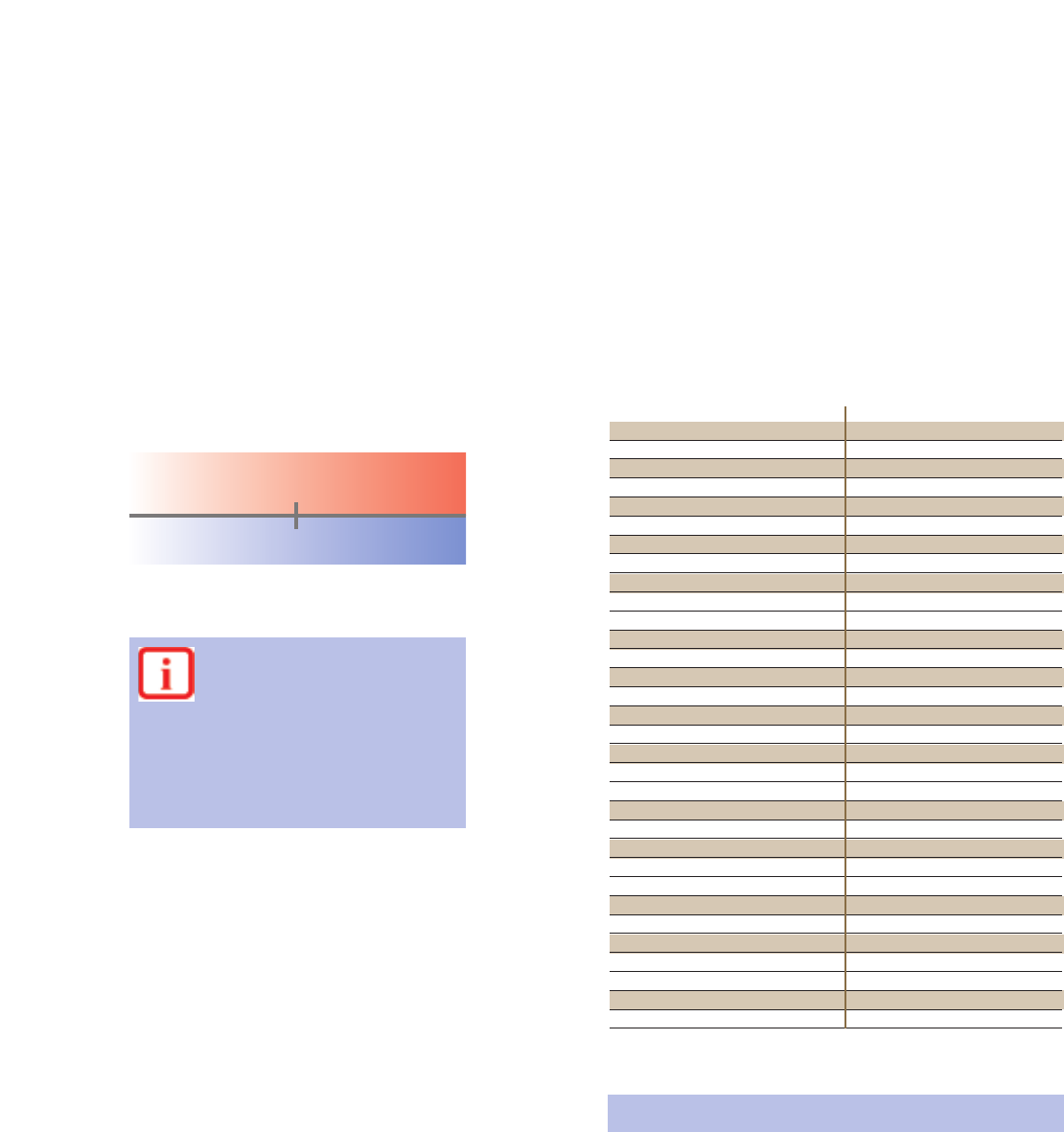

13.7 14.5 15.5

(25–500°C/ (25–500°C/ (25–500C/

77–932°F) 77–932°F) 77–932°F)

Normal cooling Long-term cooling

Ceramic furnaces of other

manufacturers often feature

opening mechanisms different

from that of Ivoclar Vivadent

furnaces. Therefore, the firing

conditions may also differ. Make

sure to observe these varying

firing conditions.

IPS d.SIGN

®

series

IPS d.SIGN

®

98

IPS d.SIGN

®

96

IPS d.SIGN

®

91

IPS d.SIGN

®

84

IPS d.SIGN

®

67

IPS d.SIGN

®

59

IPS d.SIGN

®

53

Implant series

IS

®

-85*

IS

®

-64*

High Gold content

Aquarius Hard

Aquarius

Aquarius HPF

Aquarius XH

Y-2

Y-Lite

Sagittarius

Reduced Gold content

W

Lodestar

®

W-3*

Evolution

®

Pd based

Capricorn 15

Spartan

®

Plus*

Cr or Ni base

Pisces Plus

4all

®

IPS d.SIGN

®

series

IPS d.SIGN

®

30

IPS d.SIGN

®

15

IPS Classic

* Large full coverage pontics and slow cooling should be avoided.

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

5

Indication

– Metal-ceramic veneers

Contraindication

– If patients are known to be allergic to any

of the ingredients of IPS Classic or IPS

Classic V, the material should not be used.

Important processing

restrictions

– Combination with other metal-ceramic

materials (e.g. IPS d. SIGN).

– Combination with metal-free veneering

ceramics (e.g. IPS Empress).

– Use of IPS Shade, IPS Shade V and

IPS Stains-P during the layering procedure

(e.g. between the dentin and incisal layer)

– Firing of IPS Classic onto incompatible

alloys

– Mixing of paste materials with materials in

powder form

Important information

– Ceramic furnaces of other manufacturers

often feature opening mechanisms

different from that of Ivoclar Vivadent

furnaces. Therefore, the firing conditions

may also differ. Make sure that these

varying firing conditions are taken into

account when working with IPS Classic.

Warning

– Finishing ceramic restorations results in

grinding dust. Avoid inhalation. Use

suction equipment or protective masks.

6

Composition

The IPS Classic and IPS Classic V ceramic materials and

liquids contain the following main components:

– Ceramic materials

SiO

2

: 40–65 wt. %

Additional contents are: Al

2

O

3

, B

2

O

3

, BaO, CaO, CeO

2

,

K

2

O, MgO, Na

2

O, P

2

O

5

, SnO

2

, TiO

2

, ZrO

2

and pigments

– Opaquer pastes, Shades, Stains and glazing materials

contain ceramic material and 25–40 % glycols

– IPS Classic Build-Up Liquids, N,S and L

Components: Water, butandiol and chloride

– IPS Classic Model Separator I

Components: Ethyl acetate, nitro-cellulose, softener

– IPS Classic Isolating Liquid

Component: Paraffin oil

– IPS Classic Glaze and Stain Liquid

Component: Ethylene glycol

– IPS Margin Build-Up Liquid

Components: Water and cellulose derivative

– IPS Margin Isolating Liquid

Components: Wax dissolved in hexane

– IPS Ceramic Separator

Components: Butylene acetate and pigments in nitro-

cellulose

Note:

Protect liquids from sunlight and heat!

Storage

–Protect material in powder form from moisture

– Store material in paste form at room temperature

(18-25°C/64-77°F)

7

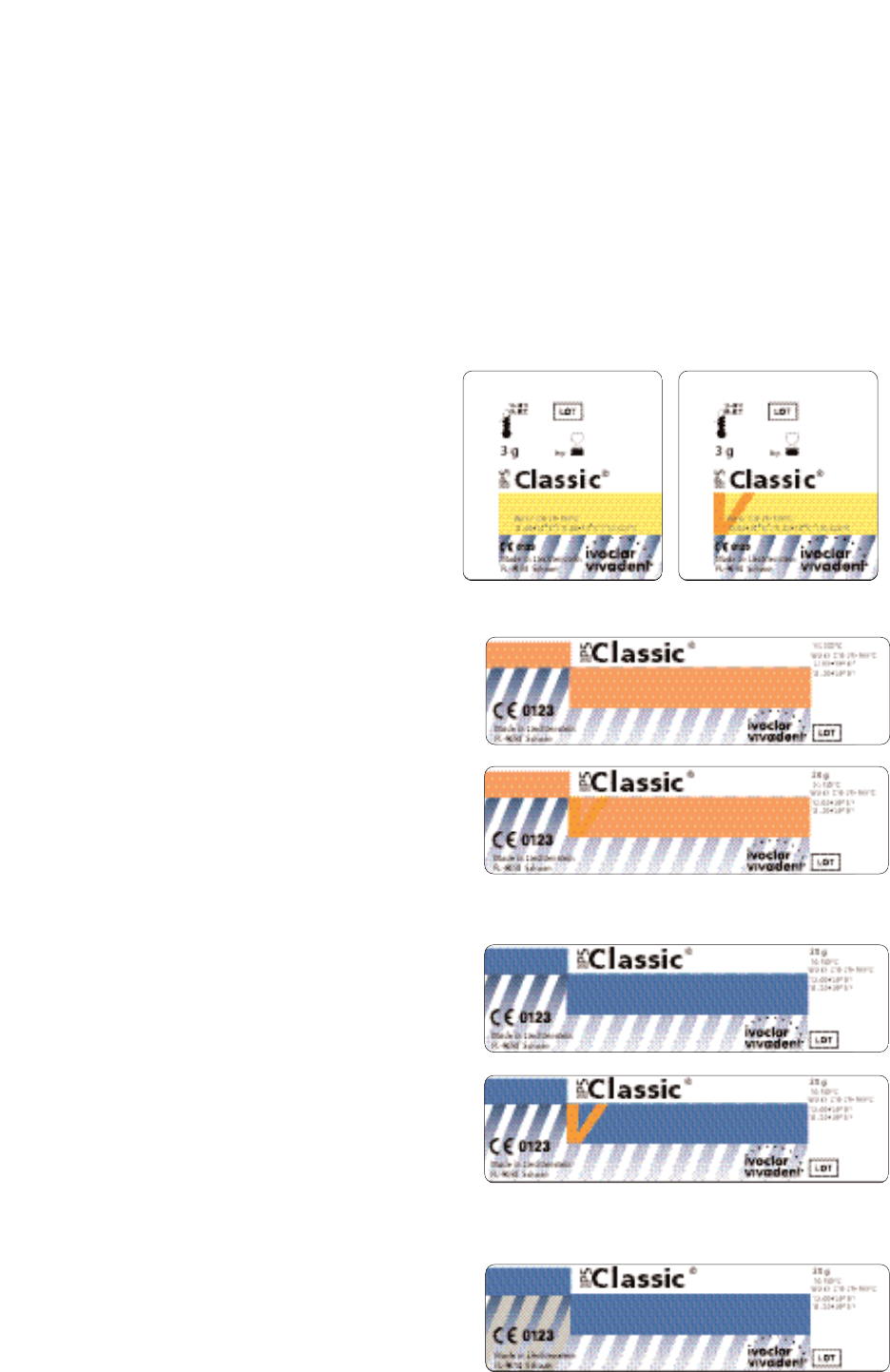

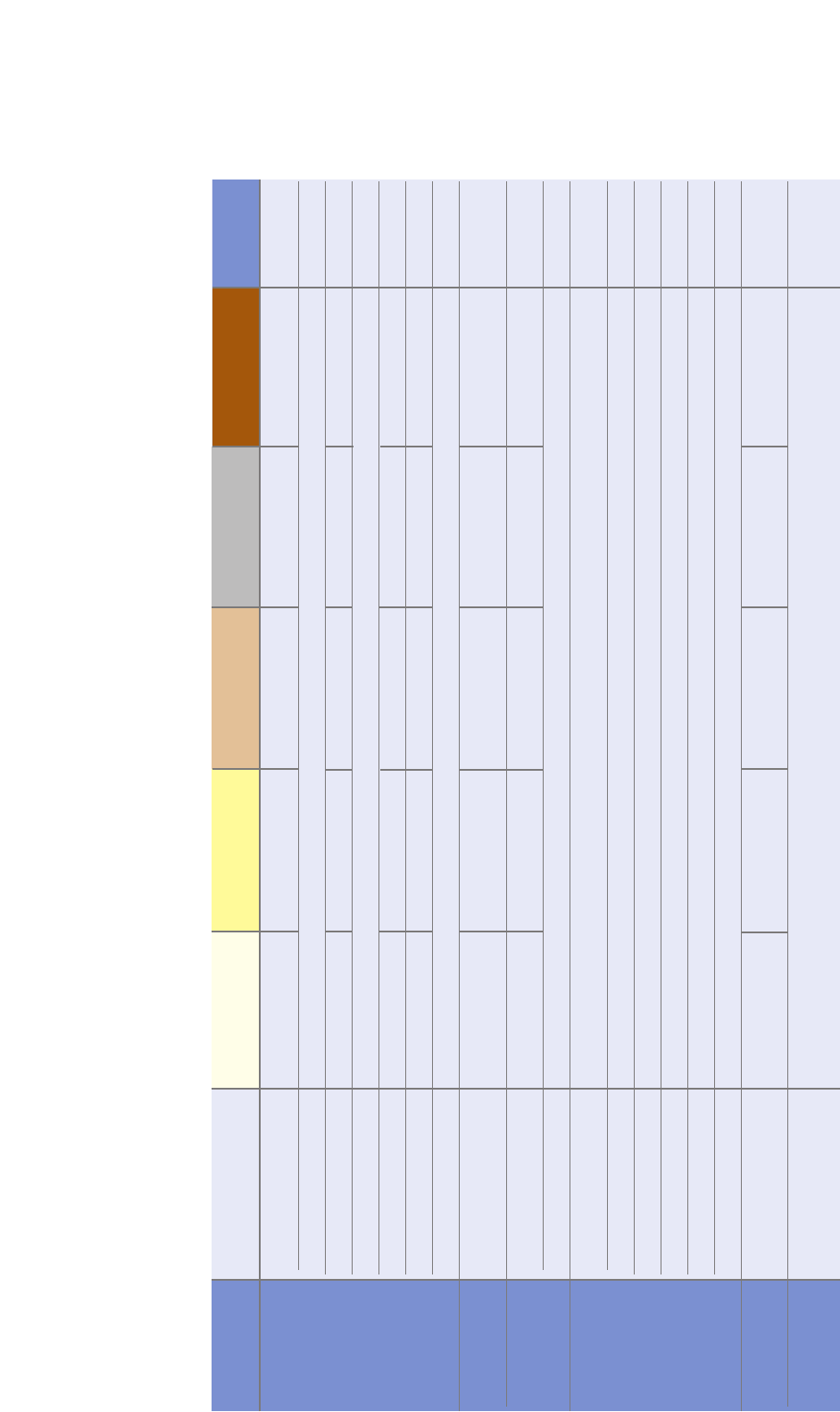

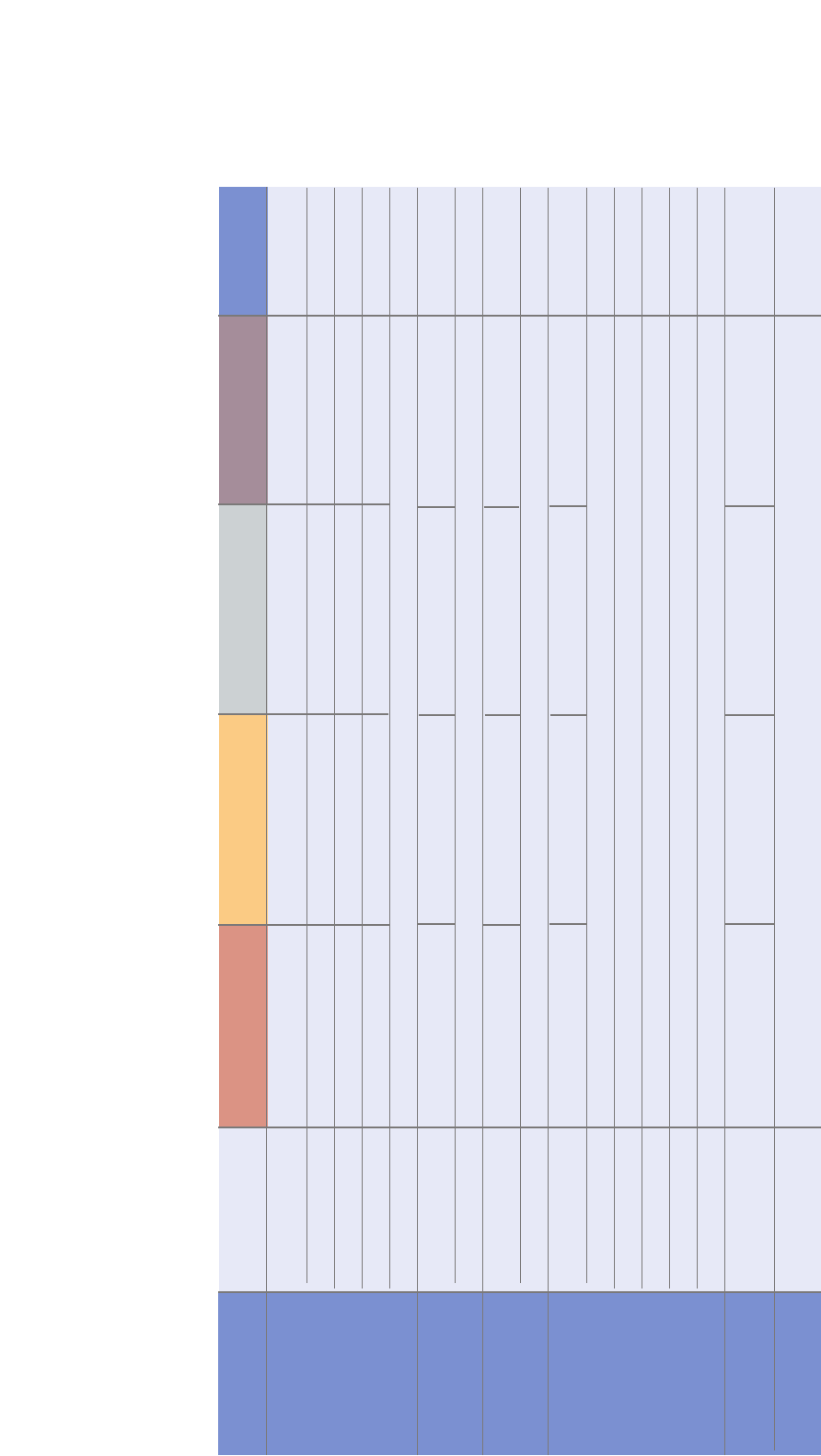

Classic and Classic V – Shade code

IPS

IPS

For a better distinction of the individual

materials labels have been selected for the

different shades. This system enables a

convenient classification of the different jars

at work.

Colouring of labels of the materials

IPS Classic Opaquer

IPS Classic V Opaquer

IPS Classic Intensive Opaquer

IPS Classic Intensive Opaquer V

IPS Classic Dentin

IPS Classic V Dentin

IPS Classic Intensive Dentin

IPS Classic Incisal

IPS Classic V Incisal

IPS Classic Transparent

IPS Classic Opal Incisal

8

IPS Margin

IPS Margin V

IPS Opaque Dentin

IPS Opaque Dentin V

IPS Impulse

IPS Impulse Incisal

IPS Effect

9

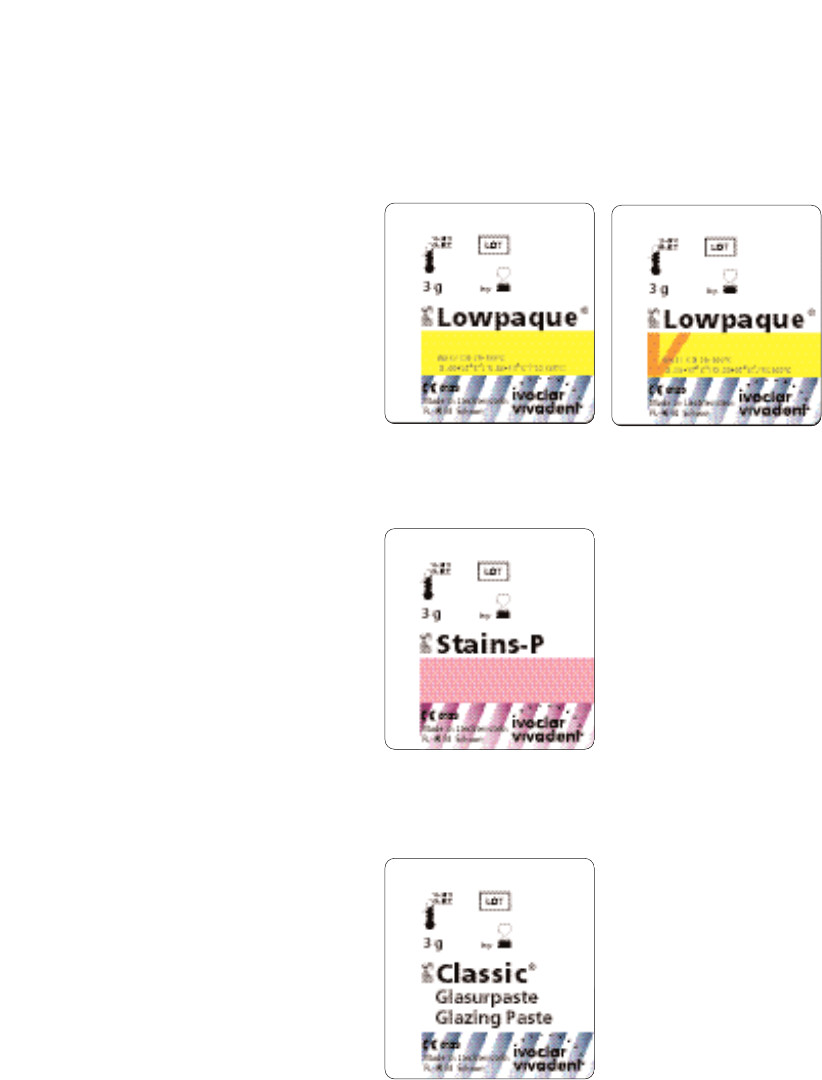

IPS Lowpaque

IPS Lowpaque V

IPS Stains-P

IPS Classic Glazing

10

Classic and Classic V –

Description of the assortments

IPS Classic Mini Kits

IPS Classic Mini Kit

IPS Classic V Mini Kit

IPS

IPS

Delivery form

IPS Classic Mini Kit (Chromascop)

–6 IPS Classic Opaquer, 3 g each

(130, 140, 210, 230, 310, 410)

–6 IPS Classic Dentin materials, 20 g each

(130, 140, 210, 310, 410, 230)

–4 IPS Classic Opal Incisal materials, 20 g each (1, 2, 4, 5)

–2 IPS Classic Transparent material, 20 g each (T-2, T-4)

–1 IPS Classic Glaze Paste, 3 g

–1 IPS Classic Glaze and Stain Liquid, 15 ml

–3 IPS Classic Build-Up Liquids, 60 ml each (L, N, S)

IPS Classic V Mini Kit

–6 IPS Classic V Opaquer, 3 g each

(A2, A3, A3.5, B3, C2, D3)

–6 IPS Classic V Dentin materials, 20 g each

(A2, A3, A3.5, B3, C2, D3)

–4 IPS Classic V Incisal materials, 20 g each (1, 2, 3, 4)

–2 IPS Classic V materials, 20 g each (Clear, Neutral)

–1 IPS Classic Glaze Paste, 3 g

–1 IPS Classic Glaze and Stain Liquid, 15 ml

–3 IPS Classic Build-Up Liquids, 60 ml each (L, N, S)

11

IPS Classic Opaquer / IPS Classic V Opaquer

Opaquer pastes have an ideal consistency and excellent

stability that ensures an outstanding masking capability even

when applied in thin layers. The opaquer pastes are

distinguished by their easy and economic processing.

Delivery form

IPS Classic Opaquer

–3 IPS Classic Opaquer, 3 g each;

Shades: 110, 120, 130, 140, 210, 220, 230, 240, 310,

320, 330, 340, 410, 420, 430, 440, 510, 520, 530, 540

IPS Classic V Opaquer

– 3 x IPS Classic V Opaquer, 3 g each;

Shades: A1, A2, A3, A3.5, A4, B1, B2, B3, B4, C1, C2, C3,

C4, D2, D3, D4

IPS Classic Intensive Opaquer / IPS Classic V Intensive Opaquer

Specially shaded intensive opaquer material pastes for

individual characterizations in the opaquer area.

Delivery form

IPS Classic Intensive Opaquer

–3 IPS Classic Opaquer, 3 g each;

Shades: white, orange, brown, violet, grey

IPS Classic V Intensive Opaquer

– 3 x IPS Classic V Opaquer, 3 g each;

Shades: A, B, C, white, violet

12

IPS Lowpaque / IPS Lowpaque V

IPS Lowpaque has been especially developed for use with

bio-alloys, most of which demonstrate a low melting point.

Given their thermal stability these bio-alloys require a low-

firing opaquer. It goes without saying, however, that

IPS Lowpaque is suitable for other ceramic alloys, in addition

to bio-alloys.

Delivery form

IPS Lowpaque

–3 IPS Lowpaque, 3 g each;

Shades: 110, 120, 130, 140, 210, 220, 230, 240, 310,

320, 330, 340, 410, 420, 430, 440, 510, 520, 530, 540

IPS Lowpaque V

– 3 x IPS Lowpaque V, 3 g each;

Shades: A1, A2, A3, A3.5, A4, B1, B2, B3, B4, C1, C2, C3,

C4, D2, D3, D4

IPS Lowpaque Intensive / IPS Lowpaque V Intensive

Specially shaded intensive opaquer pastes for individual

characterizations in the opaquer area.

Delivery form

IPS Lowpaque Intensive

–3 IPS Lowpaque, 3 g each;

Shades: IO-1 white, IO-2 orange, IO-3 brown, IO-4 violet,

IO-5 grey

IPS Lowpaque V Intensive

– 3 x IPS Lowpaque V Intensive, 3 g each;

Shades: IO A, IO B, IO C, IO white, IO violet

The product range may vary from country to country.

13

IPS Margin / IPS Margin V

The IPS Margin shoulder materials are distinguished for their

stability of shape and low shrinkage. They permit the fabrica-

tion of aesthetic crown margins that demonstrate optimum

accuracy of fit. In addition, intensive margin materials are

available for the application of special effects in the cervical

area. Since the ceramic shoulder is often located supra-

gingivally, particularly in patients suffering from periodontal

diseases, utmost shade match is required in this area.

Therefore, these materials are intended for individual

characterizations and can be mixed with ceramic shoulder

materials to imitate the typically bony effect of the root.

In addition, the shoulder materials can be mixed with each

other and also with the intensive materials (M10–M14) to

achieve a wide range of shades in the cervical area.

Delivery form

IPS Margin

– IPS Margin, 15 g each;

Shades: M1 (110), M2 (120, 130), M3 (140, 210, 220),

M4 (230, 240), M5 (330, 340) M6 (310, 320),

M7 (520, 530), M8 (540), M9 (410, 420, 430, 440, 510)

IPS Margin Intensive

– IPS Margin Intensive, 15 g each;

M10 (neutral), M11 (yellow), M12 (orange), M13 (brown),

M14 (pink)

IPS Margin V

– IPS Margin V, 20 g each;

Shades: A1, A2, A3, A3.5, A4, B1, B2, B3, B4, C1, C2, C3,

C4, D2, D3, D4

brown, yellow, orange

14

IPS Opaque Dentin / IPS Opaque Dentin V

Considering the variety of different layer thicknesses when

processing a crown or bridge and the limited space available,

a dentin material with a higher level of opacity and a more

intensive shade effect can be very helpful. These materials

can be used on their own when space is limited, and they

can be mixed with the regular dentin material. They can be

used as a substitute for dentin materials when space is

limited, as secondary dentin material in the incisal area and

the cervical, interdental and lingual area, for bridge pontics

and for mixing with the IPS Classic dentin materials.

Delivery form

IPS Opaque Dentin

– IPS Opaque Dentin materials, 20 g each;

Shades: 120, 130, 140, 210, 220, 230, 240, 310, 320,

410, 420, 430, 440, 510

IPS Opaque Dentin V

– IPS Opaque Dentin V materials, 20 g each;

Shades: A1, A2, A3, A3.5, A4, B1, B2, B3, B4, C1, C2, C3,

C4, D2, D3, D4,

brown, yellow, orange

15

IPS Classic Dentin / IPS Classic V Dentin

These dentin materials owe their vitality and shade brilliance

to the coordinated distribution of grain sizes.

Delivery form

IPS Classic Dentin

– IPS Classic Dentin materials, 20 g or 100 g;

Shades: 110, 120, 130, 140, 210, 220, 230, 240, 310,

320, 330, 340, 410, 420, 430, 440, 510, 520, 530, 540

IPS Classic V Dentin

– IPS Classic Dentin V materials, 20 g or 100 g;

Shades: A1, A2, A3, A3.5, A4, B1, B2, B3, B4, C1, C2, C3,

C4, D2, D3, D4

IPS Classic Intensive Dentin

This material is used for individualized shading of ceramic

restorations and can be mixed with any IPS Classic material.

Delivery form

IPS Classic Intensive Dentin

– IPS Classic Dentin materials, 10 g;

Shades: ID 1 (neutral), ID 2 (white), ID 3 (yellow),

ID 4 (honey), ID 5 (light brown), ID 6 (dark brown),

ID 7 (pink), ID 8 (grey), ID 9 (blue), ID 10 (clear pink),

ID 11 (red pink)

16

IPS Classic and IPS Classic V Incisal and Transparent Materials

The shade gradation of the incisal materials complement the

Chromascop and the A–D shade guides as well as the natural

incisal material. They owe their vitality and shade brilliance to

the coordinated distribution of grain sizes and the opal

effect.

The Transparent materials (T1–T4) demonstrate a shade

gradation similar to that of natural incisal areas. Additionally,

the material is available in clear and neutral.

Delivery form

IPS Classic Incisal

– IPS Classic Incisal, 20 g or 100 g;

Shades: S1, S2, S3, S4, S5

IPS Classic V Incisal

– IPS Classic Incisal, 20 g, 100 g or 250 g;

Shades: S1, S2, S3, S4

IPS Classic Opal Incisal

– IPS Classic Opal Incisal, 20 g or 100 g;

Shades: OS1, OS2, OS3, OS4, OS5

IPS Classic Transparent

– IPS Classic Transparent material 20 g or 100 g;

Shades: T1 (neutral), T2 (reddish), T3 (greyish),

T4 (transparent)

IPS Classic V Transparent

– IPS Classic Transparent material, 20 g or 100 g;

Shades: T neutral, T (clear)

17

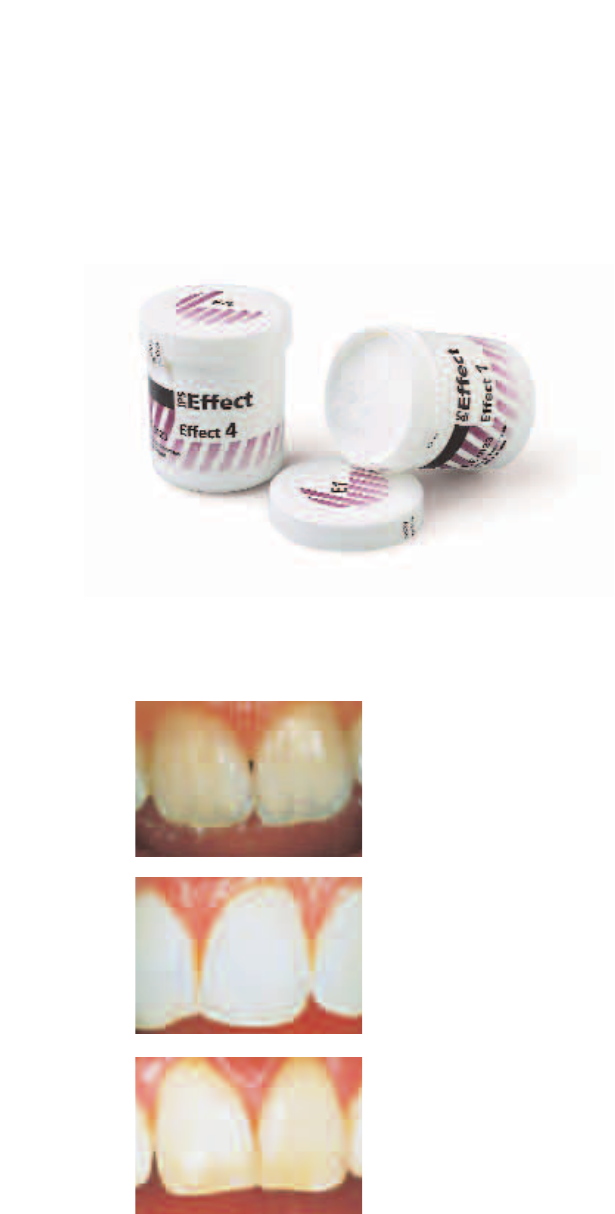

IPS Effect

These ready-mixed individual ceramic materials enable the

quick and easy reproduction of opalescent effects in the

incisal area. Users may chose between five shade gradations

of the Effect material. Starting with Effect 1, which

demonstrates true-to-nature opalescence in conjunction with

high translucency, the brightness value gradually increases

from Effect 2 to Effect 5.

Delivery form

IPS Effect

– IPS Effect, 20 g;

Shades:

E1 super opal

E2 opal

E3 whitish opal

E4 white-opal

E5 red-brown-opal

Different possibilities of application with

IPS Effect materials

IPS Effect 1

IPS Effect 2

IPS Effect 3

18

IPS Impulse

The ready-mixed individual ceramic materials facilitate the

application of true-to-nature effects.

Mamelon materials

They are available in five different shade gradations and

demonstrate high opacity and optimum masking capabilities

even when applied in very thin layers. Depending on the

working habits of the user, the material is applied in thin

stripes on reduced dentin. In this way, an individualized

appearance of the incisal third can be achieved.

Incisal Edge materials

This material is used to achieve what is known as the 'halo

effect', which is caused in natural teeth by light refraction at

the incisal edge.

Incisal materials

They are available in two shade nuances and are suitable to

modify or intensify any incisal material or can be applied

directly.

Transparent materials

The Transparent materials are available in three shade

nuances. They are suitable to imitate shaded, transparent

areas, particularly in the incisal third.

Occlusal Dentin materials

They are available in two different shades and are used to

provide the basic shade for occlusal surfaces and to intensify

the chroma.

Molar Incisal material

It is used to reproduce the whitish incisal areas especially in

posterior teeth. However, it can also be mixed with any

incisal material to imitate the whitish incisal areas in anterior

teeth.

Delivery form

IPS Impulse

– IPS Impulse Mamelon materials, 20 g;

Shades: MM1, MM2, MM3, MM4, MM orange

– IPS Impulse Incisal Edge materials, 20 g;

Shades: yellow, light-yellow

– IPS Impulse Incisal materials, 20 g;

Shades: yellow-grey, grey

– IPS Impulse Transparent materials, 20 g;

Shades: blue, yellow-grey, grey

– IPS Impulse Occlusal Dentin materials, 20 g;

Shades: brown, yellow, orange

– IPS Impulse Molar Incisal material, 20 g;

Shade: MS

19

IPS Gingiva

The IPS Gingiva materials are suitable for aesthetic solutions

that require true-to-nature reproduction of the gingival area

for metal-ceramic restorations or implant superstructures in

accordance with natural gingival shades and characteristics.

The ready-mixed ceramic materials are used to

–reproduce natural gingiva

– mask long cervicals in bridge restorations

– fill large interdental spaces and

– to mask those areas of implant superstructures facing the

gingiva

The pink opaquer paste is used to mask the marginal areas in

metal frameworks or implant superstructures. The four

Gingiva modifiers can be used alone or mixed with the five

Gingiva materials depending on the patient’s situation.The

shade gradations range from orange to reddish to bluish.

Delivery form

IPS Gingiva Opaquer

– IPS Gingiva Opaquer, 3 g;

Shade: pink

IPS Lowpaque Gingiva

– IPS Lowpaque Gingiva, 3 g;

Shade: pink

IPS Gingiva

– IPS Gingiva, 20 g;

Shades: G1, G2, G3, G4, G5

IPS Gingiva Modifier

– IPS Gingiva Modifier, 20 g;

Shades: GM 1, GM2, GM3, GM4

20

IPS Shade / IPS Shade V

The ready-mixed dentin stains in paste form permit

subsequent modification of shades on the fired ceramic

restoration.

Delivery form

IPS Shade

– IPS Shade, 3 g;

Shades: 110/120, 130, 140/210, 220/230, 240, 310, 320,

330, 340, 410/420, 430/440, 510, 520, 530, 540

IPS Shade V

– IPS Shade V, 3 g;

Shades: A1, A2/A3/A3.5, A4, B1, B2/B3/B4, C1/C2, C3/C4,

D2/D3, D4

IPS Stains-P

These stains in paste form permit easy, individualized charac-

terization of the restorations. The countless possibilities of

mixing the shades ensure virtually unlimited creativity.

Delivery form

IPS Stains-P

– IPS Stains-P, 3 g;

Shades: white, bamboo, caramel, copper, cork, mahogany,

azure, black, orange, basic yellow, basic red, basic blue

21

IPS Classic Glazing Paste

Easy-to-use glazing material in paste form for a true-to-

nature gloss on ceramic restorations.

Delivery form

IPS Classic Glaze

– 5 x 3 g IPS Glazing paste

IPS Classic Correction Powder

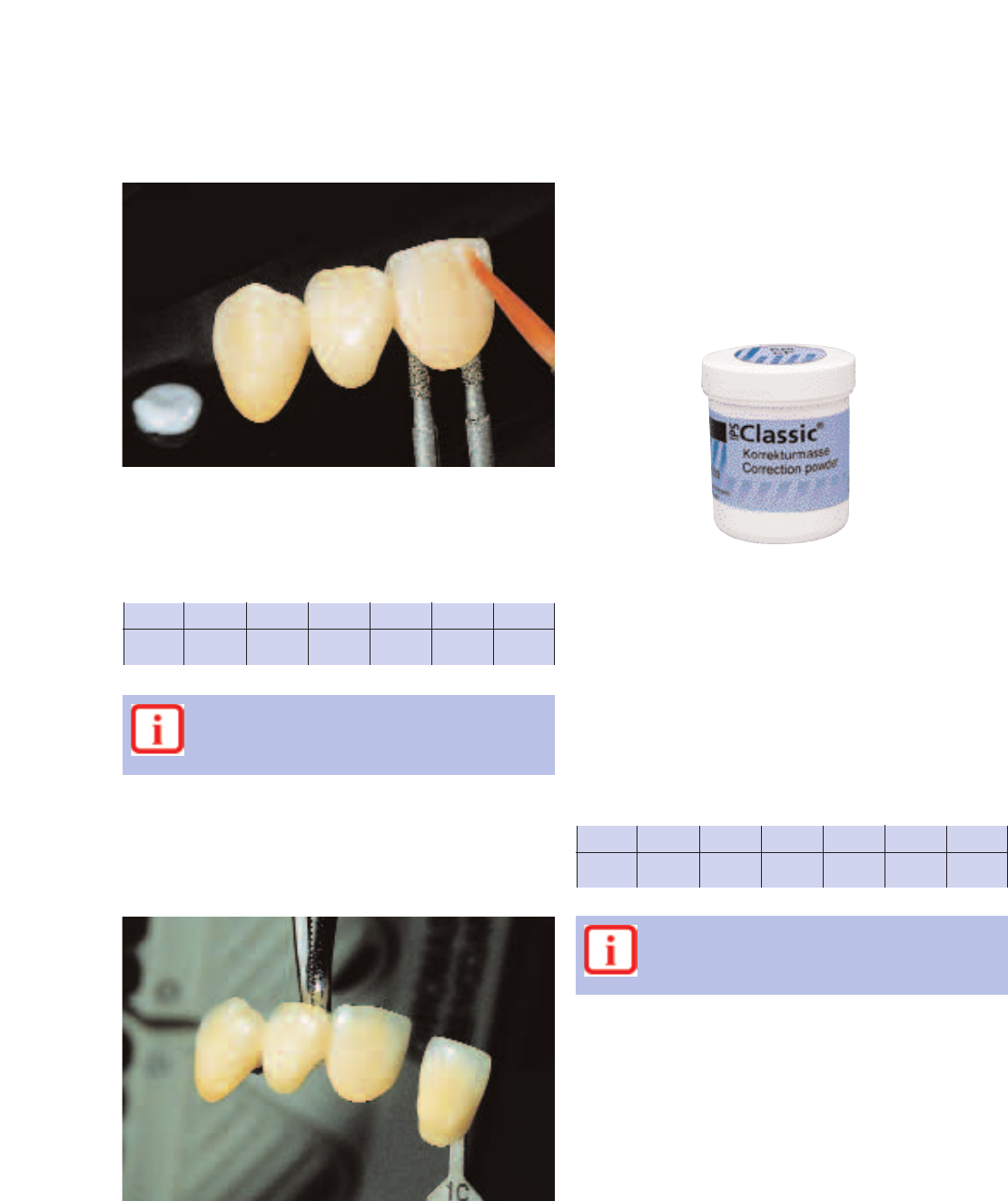

The low-fusing correction powder for IPS Classic and

IPS Classic V ceramics is particularly suitable for small

corrections and shape adjustments of completely fired

restorations.

Delivery form

IPS Classic Correction Powder

– IPS Correction Powder, 20 g; shade: neutral

22

IPS Classic Glaze and Stain Liquid, 15ml

This liquid is used to adjust

the consistency of

IPS Shades, IPS Shades V,

IPS Stains P and IPS Classic

Glaze.

IPS Classic Build-Up Liquid N (Normal), 60 ml, 250 ml and

500 ml

This build-up liquid is

particularly suitable for

technicians who apply small

amounts of ceramic material

using the brush. It provides

enhanced stability and has

excellent modelling

properties. The Build-up

Liquid N is particularly

suitable for those who prefer

a moist working consistency

without constantly rewetting

the ceramic material. As

indicated by the description

‘N’ (normal liquid) this build-

IPS Margin Build-Up Liquid, 60 ml

This special build-up liquid

facilitates the build-up of

ceramic shoulders. Due to a

subsequent setting the use

of this liquid enables an easy

removal of the contoured

crown from the working die.

Classic – Liquids

IPS

IPS Classic Build-Up Liquid L (Long Term), 60 ml, 250 ml

and 500 ml

This liquid has been

developed for technicians

who desire a longer working

time and for markets in

warmer regions. A

component has been added

to the Build-up Liquid ‘L’

which increases the boiling

point and enables the liquid

to evaporate at a slower

pace. This results in a pro-

longed working time while

preserving the excellent

modelling properties.

IPS Classic Build-Up Liquid S (Spatula Technique), 60 ml,

250 ml and 500 ml

This liquid is particularly

suitable for technicians who

tend to strongly condense

the materials, use blotting

material and subsequently

reduce the restorations using

an instrument. The liquid is

easily blotted from the con-

toured crown. This results in

a relatively solid material

which can be shaped with a

suitable instrument.

up liquid is intended for

daily use and for most

layering techniques.

IPS Classic Glaze and Stain Liquid contains ethylene

glycol and is hazardous to health. Do not inhale

vapours. Avoid skin and eye contact.

IPS Build-up Liquids N, L and S can be diluted with

distilled water.

23

IPS Margin Isolating Liquid, 20 ml

This isolating liquid has been

developed to ensure easy

removal of the contoured

shoulder from the die. It

forms a water-repellent film

on the surface, thus

preventing liquids from

seeping into the stone die.

IPS Classic Ceramic Separator contains butylene

acetate. Do not inhale the vapours. Butylene ace-

tate is highly flammable. Keep material away from

open fire.

IPS Margin Isolating Liquid contains hexane.

Hexane is highly flammable and detrimental to

health. Avoid contact of the material with skin and

eyes. Do not inhale the vapours. Keep the material

away from the open fire.

IPS Classic Model Separator contains ethyl acetate.

Ethyl acetate is highly flammable. Do not inhale the

vapours. Keep material away from open fire.

IPS Classic Model Separator I, 50 ml

This separator is ideally used

for sealing the stone models

used for ceramic work. The

Model Separator keeps the

ceramic materials moist.

Within approx. 2 minutes

the applied liquid has dried

and the pores of the stone

are sealed.

IPS Classic Ceramic Isolating Liquid, 50 ml

The Ceramic Isolating Liquid

ensures reliable separation of

the ceramic material and

stone model. The liquid is

used once the stone has

been sealed using the Model

Separator or the IPS Margin

Isolating Liquid.

IPS Classic Ceramic Separator, 10 ml

Ceramic Separator is used in

situations where two ceramic

layers need to be separated.

Furthermore, it is excellently

suitable to isolate the

ceramic material during

soldering (to protect the

ceramic surface from flux).

The Ceramic Separator

varnish fires without leaving

residue. It is important,

particularly with overlapping

teeth, to first complete

and fire one tooth and

subsequently to cover it with

the Ceramic Separator.

Then, contour the adjacent

overlapping tooth onto the

fired one. In this way, a

clean separation between

the two ceramic layers is

achieved after firing.

IPS

24

The Chromascop shade

guide represents the shade

standard for Ivoclar Vivadent

products. With the logical

arrangement of the

individual shades, the

Chromascop permits exact

and efficient shade deter-

mination. The 20 shades are

divided into five detachable

shade groups. Once the

basic shade has been

selected, the correct shade

within the shade group can

be determined. Ignoring any

superfluous effects (e.g.

cervicals, transparent areas,

intensive discolouration in

the incisal and dentin

areas, as well as surface

characterizations) makes it

much easier to determine

the correct shade. The follo-

wing Ivoclar Vivadent pro-

ducts are coordinated with

the Chromascop shade

guide:

– IPS d.SIGN

– IPS Empress

– IPS Empress 2

– IPS Eris for E2

– SR Ivocron

– SR Antaris/SR Postaris

tooth line

–Tetric Ceram

restorative materials

Classic – Shade selection

25

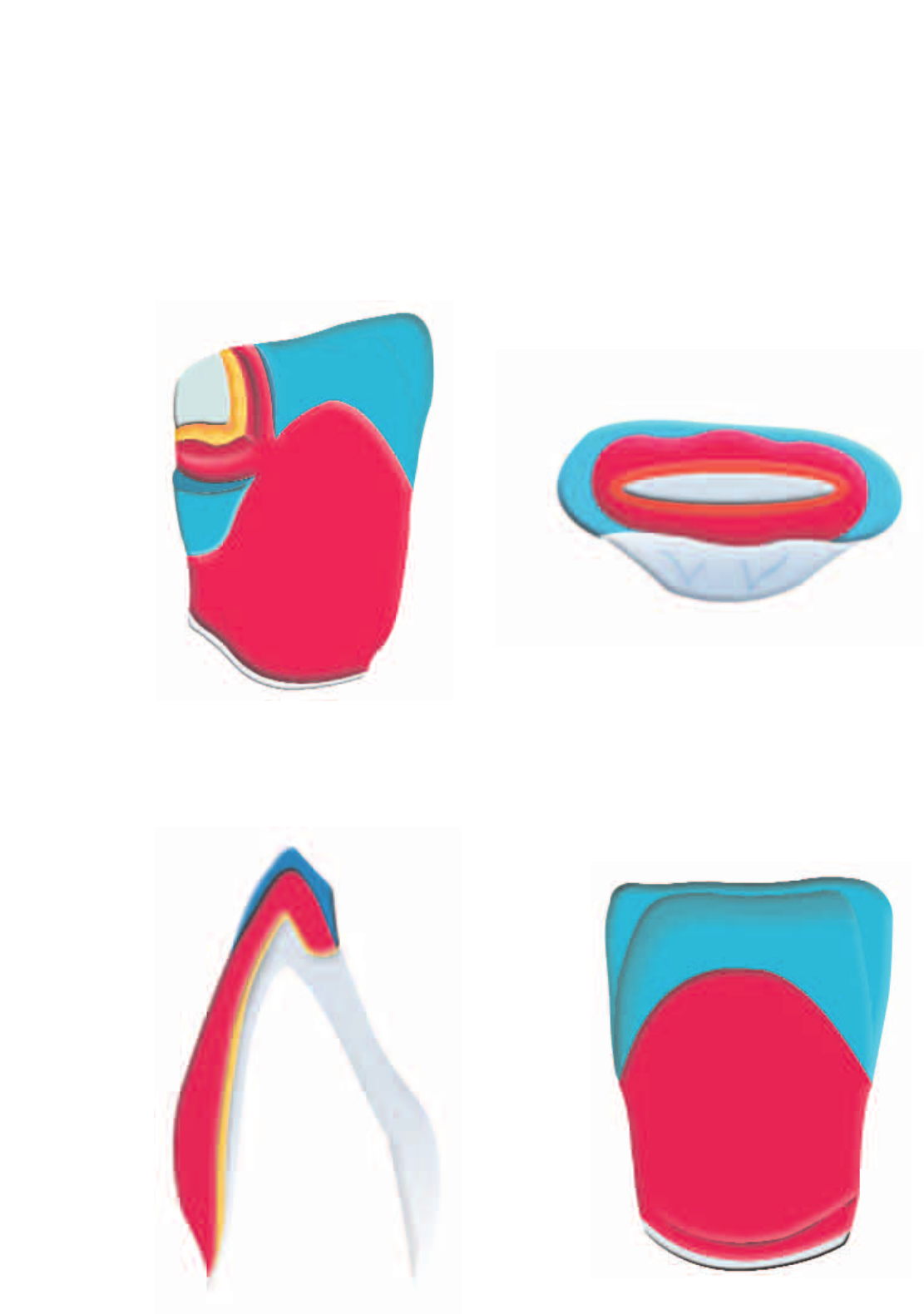

Classic – Layering diagram

IPS

Chromascop

26

Classic – Framework design

IPS

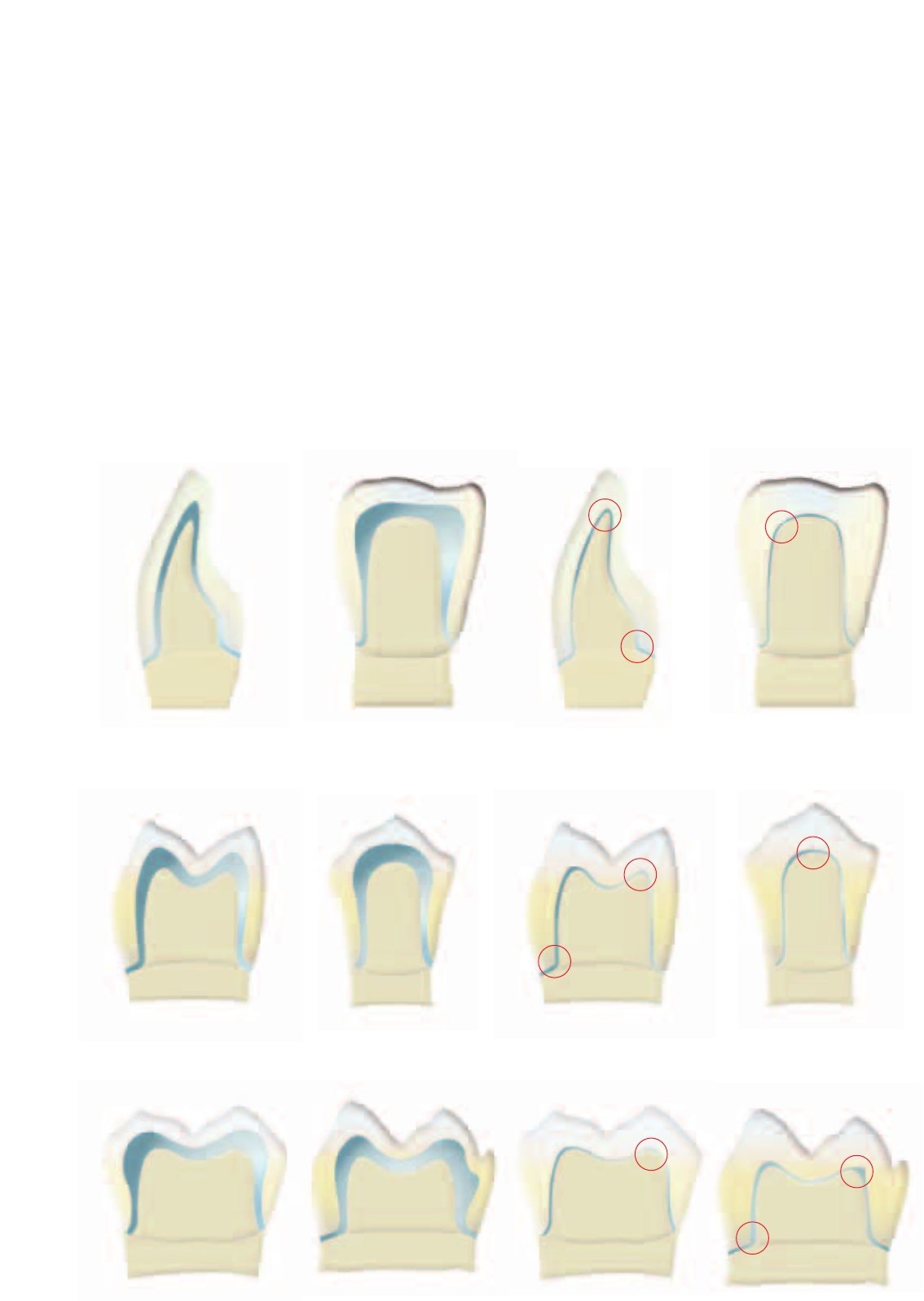

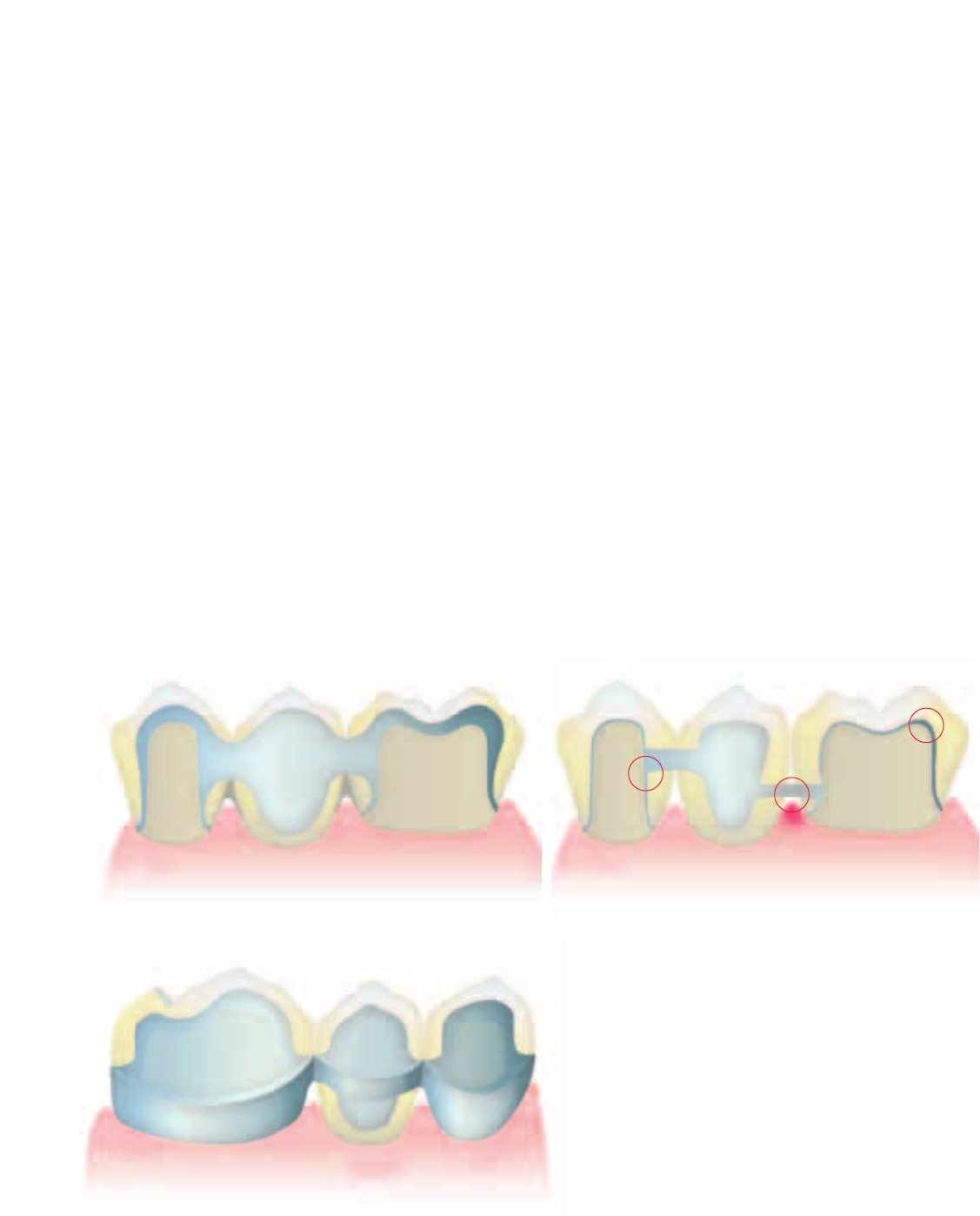

1. Functional support of the veneering ceramic

2. Framework design for ceramic shoulders

3. Framework stability

4. Framework design for bridges

5. Design of bridge pontics

6. Interface between metal and ceramic

When designing frameworks to be

veneered with ceramic materials, the

following parameters have to be

observed:

27

The framework should reflect the shape of the tooth in a

reduced form. Therefore, the framework should be designed

in such a way that it supports the cusps so that an even

layer of the veneering ceramic can be used in the cusp/

fissure area. In this way, the masticatory forces are exerted

on the framework rather than on the veneering ceramic.

Furthermore, the framework should not have any sharp

angles or edges (see diagram), so that the masticatory forces

Anterior crowns

correct incorrect

do not cause delamination or cracks. Sharp angles or edges

should be rounded out in the wax-up so that the minimum

framework thickness is not compromised. The wall thickness

of the metal framework for single crowns after finishing

should be at least 0.3 mm and 0.5 mm for bridge

abutments (see diagram). For further information, please

refer to the Instructions for Use of the alloy being used.

1. Functional support of the veneering ceramic

Premolar crowns

Molar crowns

correct incorrect

correct incorrect

28

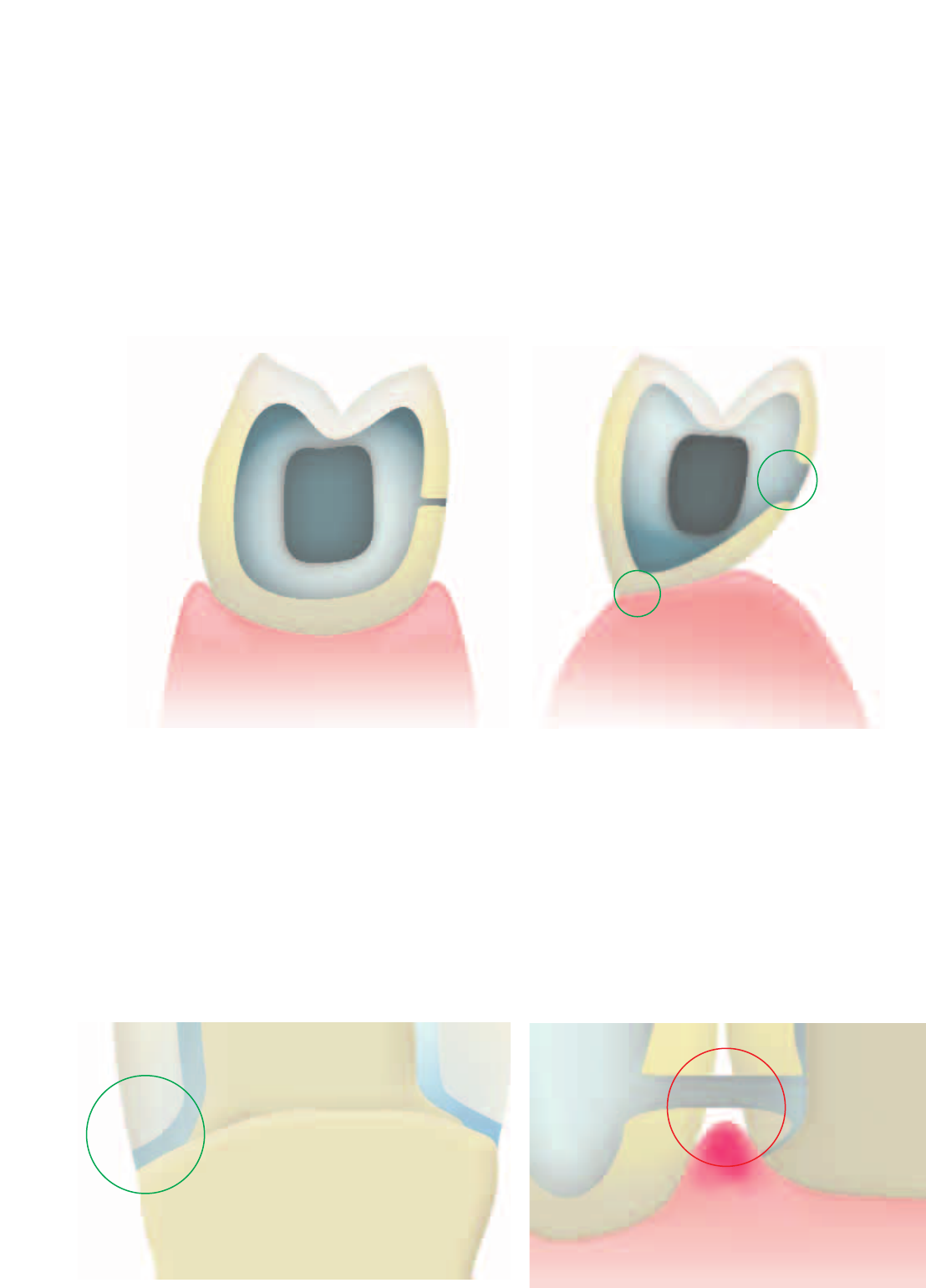

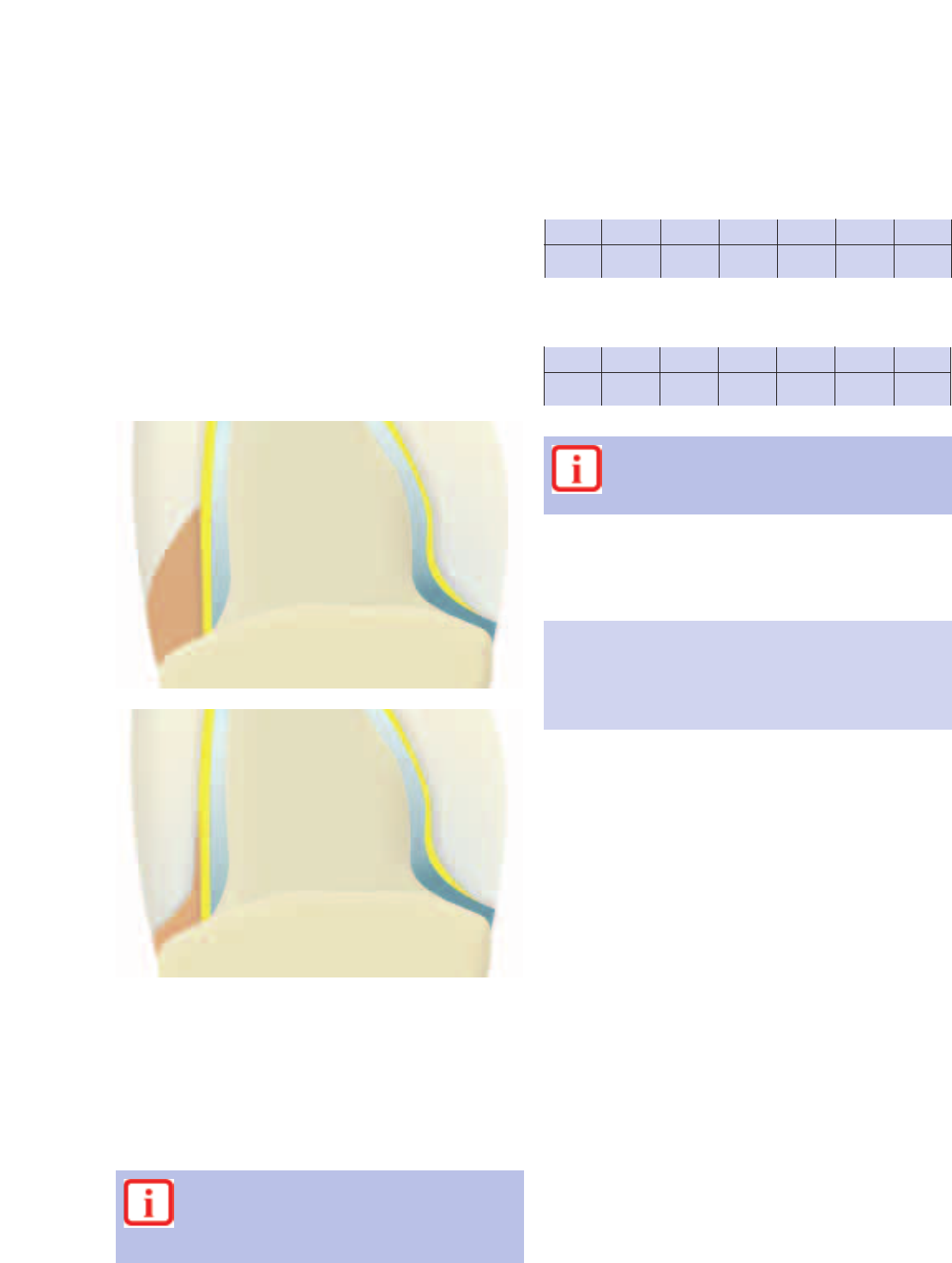

When fabricating porcelain shoulders, make sure that the

framework is supported by the prepared tooth rather than

by the veneer. To achieve this, the framework is reduced to

the inner edge of the chamfer or shoulder preparation. In

this way, functional support of the framework by the tooth

is achieved. A framework that accurately fits on the

prepared tooth is essential in order to keep the ceramic

material from getting on the inner surface of the framework.

2. Framework design for porcelain shoulders

incorrect

correct

Single connector width

= single stability

Double the width of

the connector

= double the strength

Double the height of the

connector at single width

= eightfold the strength

3. Framework stability

The dimensions of the interproximal connector greatly

influences the stability of the restoration during the

laboratory procedure, as well as the clinical long-term

success after cementation. Therefore, the dimensions of the

connector areas must be adequate for the alloy being used.

(This is especially important if a bio-alloy or high-gold alloy is

to be used.) Additionally, the thermal behaviour of the alloy

chosen has to be observed when applying the material

during laboratory procedures.

29

Frameworks veneered with ceramic materials are subject to

thermal stress during the firing procedures and to

masticatory stress after cementation. Therefore, the

corresponding forces must be transferred to the framework

rather than the veneer. In particular, adequate framework

thickness must be ensured in the connector area between

the abutment and the pontic.

The design of the framework must meet the visual,

functional and periodontal hygiene requirements of the

patient. A functional wax-up reduced to allow space for the

ceramic material is the optimum prerequisite. During the

ensuing laboratory procedures, the framework is repeatedly

exposed to high temperatures. These firing temperatures

may cause the framework to distort and compromise the

accuracy of fit if it has not been properly designed and the

required thickness observed. A scallop-type design with

interproximal reinforcements will provide the necessary

strength needed to avoid deformation of the framework.

Also, this type of framework design (e.g. with cooling vents)

will ensure even cooling of the restoration once it is removed

from the ceramic furnace after firing. This is particularly

important if bio-alloys or high-gold alloys are used. The

corresponding failures can be prevented as described under

point 1.

In order to ensure proper oral hygiene with bridges, the

design of the interdental areas should be given special

attention. Adequate opening of the interdental area should

be considered when designing the framework without

creating black triangles. In this way, periodontal hygiene may

be performed using interdental brushes and dental floss.

4. Framework design for bridges

correct

correct

incorrect

30

Bridge pontics are designed taking aesthetic and functional

aspects into account as well as oral hygiene. The area of the

pontic that contacts the alveolar ridge should be made of

ceramic. In order to ensure adequate stability between

bridge pontic and the bridge abutments, a palatal and/or

lingual scallop is recommended. Furthermore, to ensure even

cooling of the bridge pontic that absorbs the most heat,

cooling vents are advantageous.

5. Design of bridge pontics

The interface between the metal framework and the

veneering ceramic must be clearly defined and, if possible,

incorporate a right angle finish line. The juncture between

the metal framework and the veneering ceramic must not

be located in the contact area, nor on surfaces involved in

masticatory functions. Furthermore, make sure that the

interface in the marginal area does not come into contact

with the gingiva, particularly if a tapered crown margin is

designed (e.g. no metal margin and no ceramic shoulder). In

this way, irritation of the gingiva can be prevented. The

interface in the interdental area should be designed in such

a way that cleaning of these areas is possible.

6. Interface between metal and ceramic

Bridge pontic design - ovate pontics Bridge pontic design - saddle-type pontics

31

Classic – Instructions for Use

IPS

Oxide firing

After grinding, carefully blast the framework with type

100 aluminium oxide Al

2

O

3

(Ivoclar Vivadent special jet

medium). The required pressure is 1.5–2.0 bar.

– Use only disposable, pure Al

2

O

3

to blast the alloy surface.

– Observe the Instructions for Use of the alloy manufacturer.

Blasting improves the mechanical bond. It results in the

object surface being roughened and considerably enlarged.

In order to prevent inclusions of blasting medium residue in

the ceramic, we recommend blasting the alloys with the

indicated pressure while keeping the nozzle at a flat angle to

the object surface. A contaminated metal surface may result

in the formation of bubbles during ceramic firing. When

finishing the frameworks, the instructions of the alloy

manufacturer must be observed at all times. Oxidation is

carried out according to the instructions of the alloy

manufacturer.

Starting situation

Fabricate a master model or a model with detachable

segments on the basis of the impression in the usual manner.

It is advisable to apply a sealer to harden the surface and to

protect the die. The application of a sealer must not cause

any changes in the dimensions of the die. After that, a

spacer may be applied in the usual manner.

Fabricating the framework

Fabricating the framework

When fabricating the framework, make sure that the

minimum wall thickness after finishing is 0.3 mm for single

crowns and 0.5 mm for bridge abutments. These dimensions

are the prerequisite for the stability of the metal framework

and the durable bond between the metal and ceramic

material. If the stipulated framework and connector

dimensions are not observed, the resulting stress within the

material will lead to delamination of the ceramic material

and distortion of the framework.

Recommended procedure

1. Complete modelling of the anatomical tooth shape

2. Reduce to make room for the veneering materials

3. Waxing of the contact points and connector areas

4. Checking the occlusal and proximal contact points

Contouring

The framework reflects the reduced anatomical tooth shape

(functional support of the veneering ceramic). In this way, the

ceramic material may be applied in even layers and is

adequately supported. For that purpose, the properties of

the different alloys (e.g. firing stability) must be taken into

consideration.

– Undersized metal frameworks result in increased shrinkage

of the veneering ceramic and require additional corrective

firings.

– If the metal framework is too small, the veneering ceramic

is not adequately supported, which may lead to cracks and

delamination, particularly in very thick ceramic layers.

Finishing the metal framework

The cast metal framework is finished using tungsten carbide

metal burs or ceramic-bonded grinding instruments. The

marginal area of the framework is reduced up to the inner

edge of the chamfer or shoulder preparation (labial or

circular) to make room for the ceramic shoulder.

– Use reduced pressure when working with softer alloys.

–Work in one direction only to avoid overlapping and

inclusions in the metal surface.

– Do not use diamond grinding instruments. Diamond

particles may be trapped in the alloy and cause bubbles in

the ceramic material during firing.

Schematic diagram of the

blasting direction

Correct angle for blasting the

alloy surface

Before the oxidation firing, clean the metal framework using

a brush under running water. Then, thoroughly clean it with

steam or in the ultrasonic cleaner. Allow the framework to

dry after cleaning. Oxidize the framework according to the

instructions given by the alloy manufacturer. Provide ample

support for the framework on the firing tray. This is

particularly important for long-span bridges. After oxidation,

carefully check the framework for porosity or irregular oxide

layer. Refinish and reoxidize if necessary.

Apply the first opaquer layer (wash) thinly using a brush.

Firing parameters for the 1

st

opaquer firing (wash

firing) – IPS Classic Opaquer

Firing parameters for the 1

st

opaquer firing (wash

firing) –IPS Lowpaque

Important

If furnaces from other manufacturers are used,

these parameters have to be adjusted accordingly.

32

1

st

opaquer firing (wash firing)

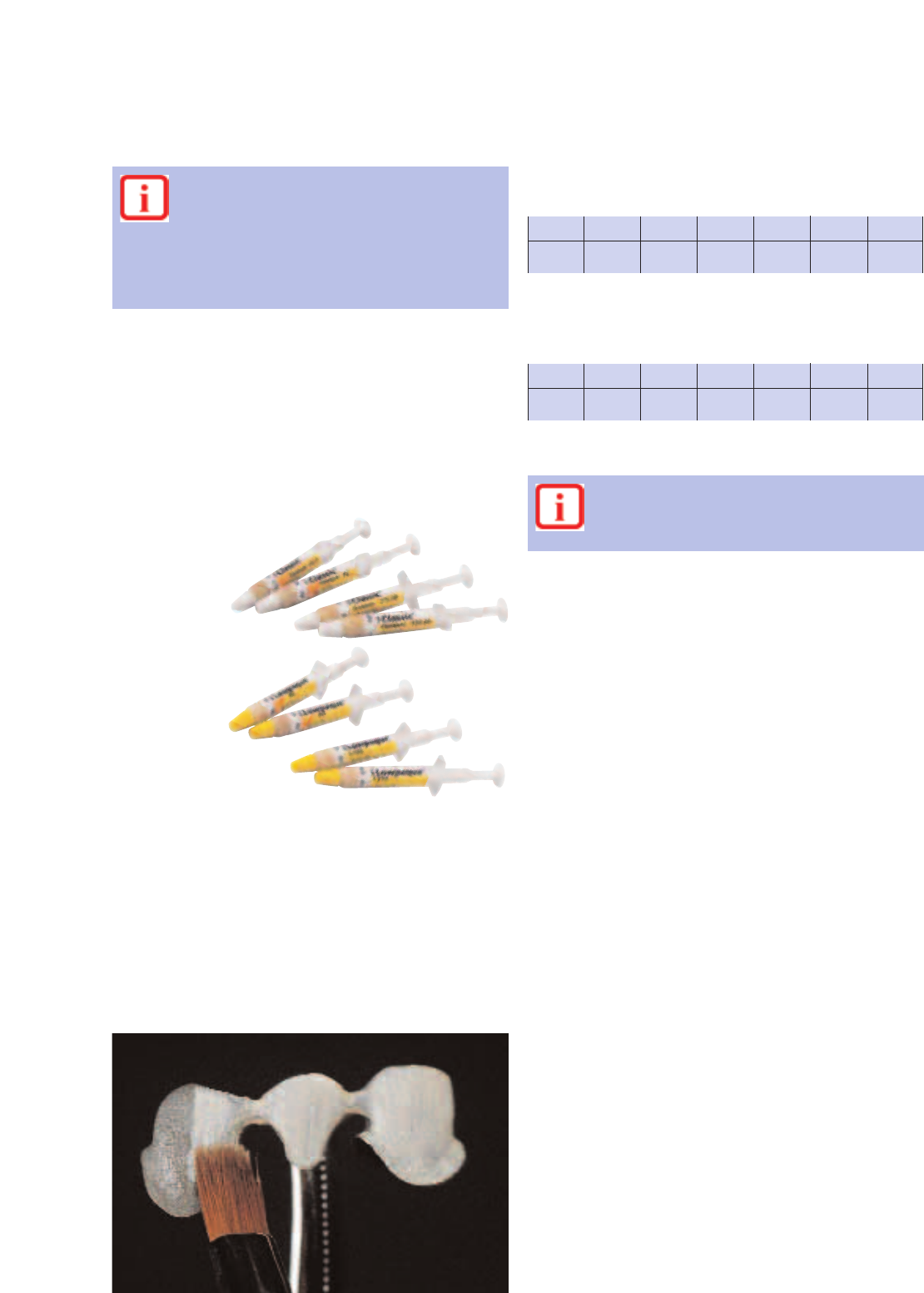

Extrude the desired amount of the ready-to-use opaquer

paste from the syringe and mix thoroughly.

Choose between the

IPS Classic Opaquer

or

IPS Lowpaque

The IPS Classic Glazing and Staining Liquid is used to adjust

the consistency of the paste opaquer and to rewet dried

opaquer that has been used several times. Do not dilute the

material with water.

Apply the first opaquer layer (wash) thinly using a brush.

Smooth out any roughness on the metal surface, since the

wash is the most important connection between the metal

oxide surface and the ceramic.

Some alloy types require pickling after oxide firing

and/or blasting of the oxide layer (observe

instructions of the alloy manufacturer). After that,

thoroughly clean the framework with steam or in the ultra-

sonic bath. Oxidation can be considered a 'cleaning firing'

and is also used to check the quality of the framework

surface.

T

980°C

1796°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

979°C

1794°F

➚

T

920°C

1688°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

450°C

842°F

V

2

919°C

1686°F

➚

33

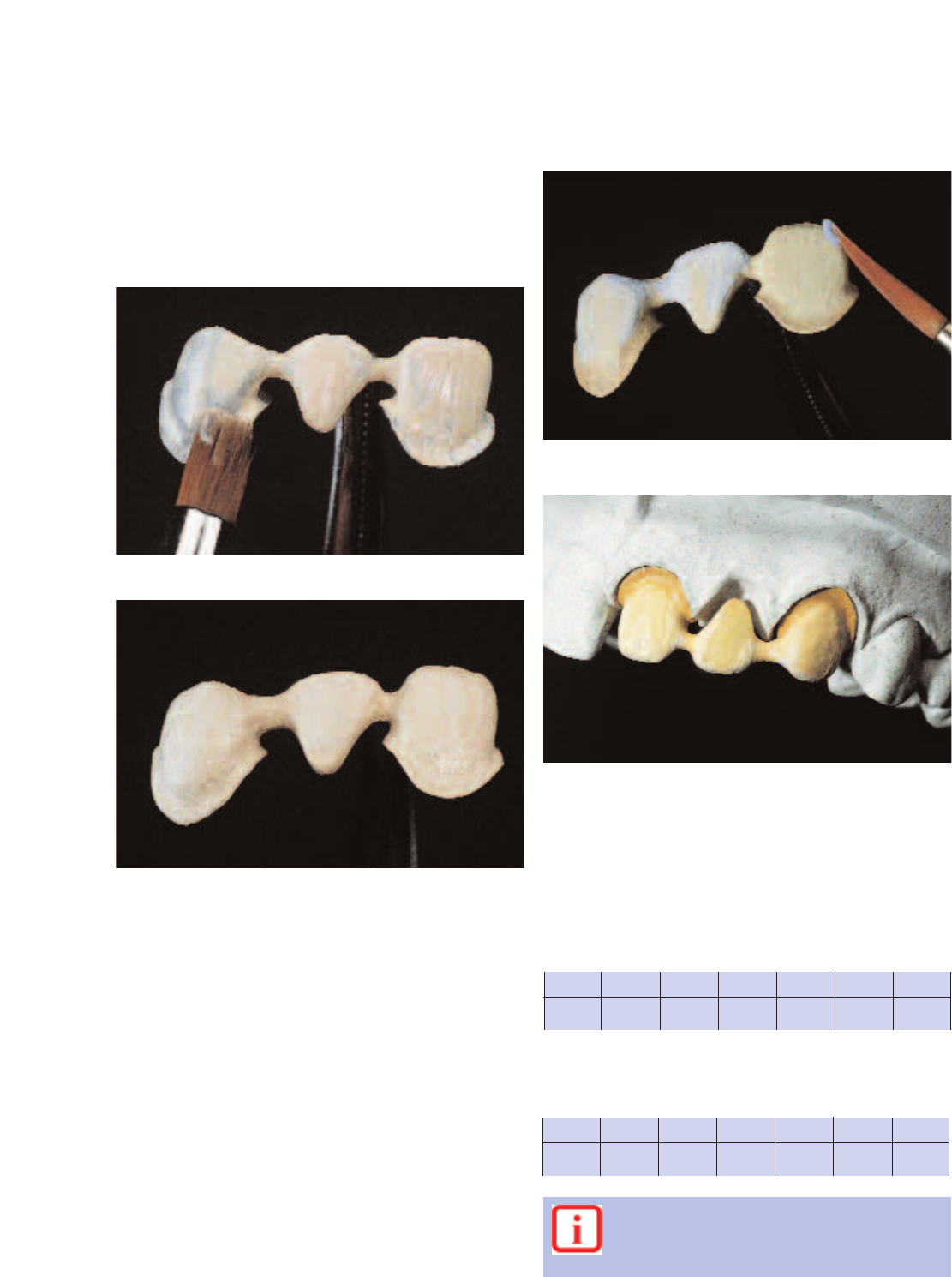

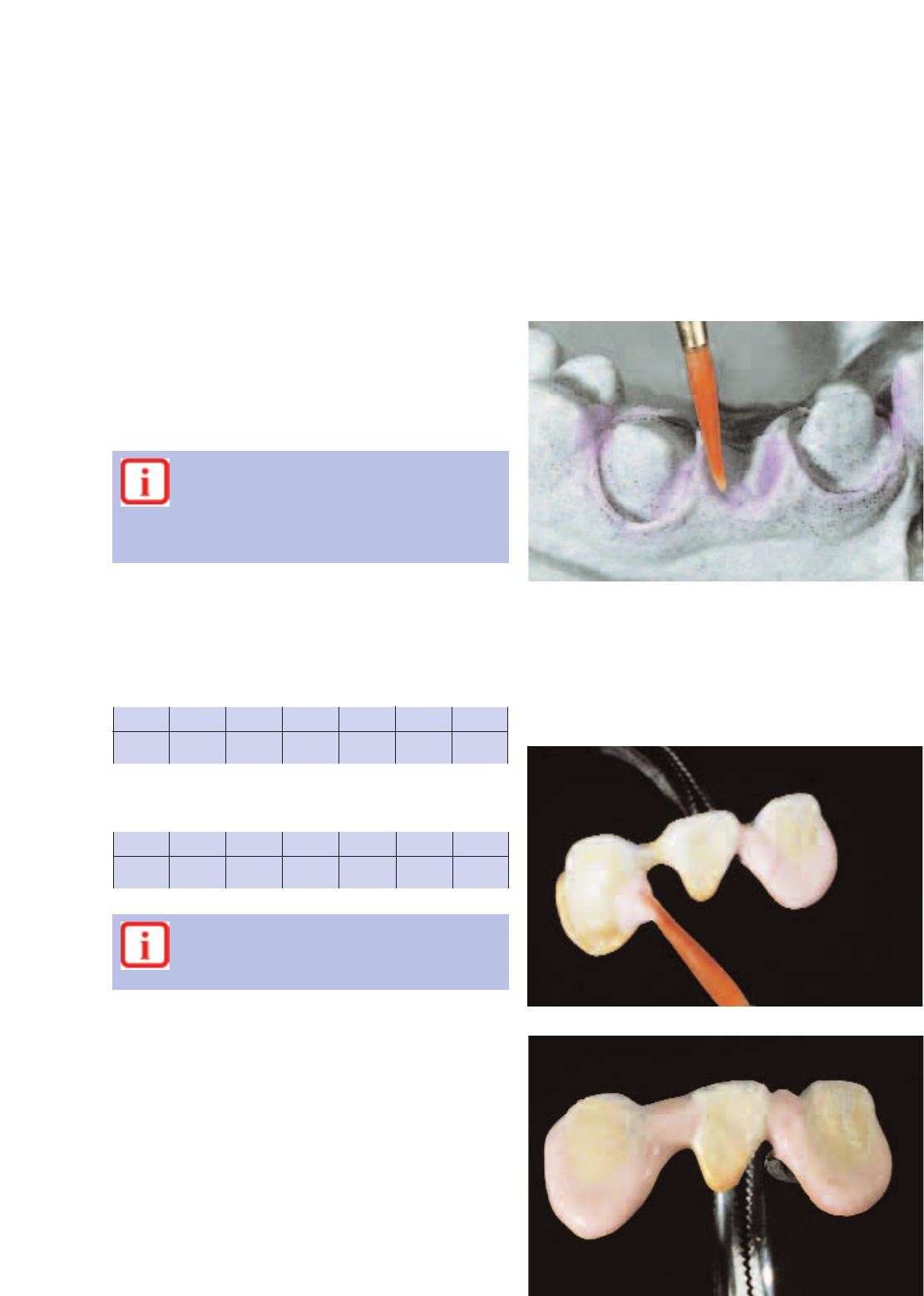

Apply Intensive Opaquer onto the desired areas…

Apply the 2

nd

opaquer layer so ...

2

nd

opaquer firing

Apply the second opaquer layer in such a way that the metal

framework is entirely covered with opaquer, i.e. as much as

necessary and as little as possible.

... subsequently, the restoration is fired using the stipulated firing parameters for the second opaquer firing

... that it covers the entire framework

Important

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

Firing parameters for the 2

nd

opaquer firing –

IPS Classic Opaquer

Firing parameters for the 2nd opaquer firing –

IPS Lowpaque

For each individual situation, five ready-mixed Intensive

Opaquers are available to meet exacting, aesthetic

requirements. The Intensive Opaquers are applied before

the second opaquer firing in the desired areas (e.g. in the

cervical, incisal, occlusal, or palatal area).

The fired opaquer should have a silky-mat appearance

(egg-shell gloss).

T

970°C

1778°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

969°C

1776°F

➚

T

910 °C

1670 °F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

450°C

842°F

V

2

909°C

1668°F

➚

Firing parameters for the 1

st

margin shoulder firing –

IPS Classic Opaquer

Firing parameters for the 1

st

margin shoulder firing –

IPS Lowpaque

Important

If furnaces from other manufacturers are used,

these parameters have to be adjusted accordingly.

Important:

Please consider the different firing parameters of

the margin shoulder firings when using IPS Classic

Opaquer or IPS Lowpaque.

34

1

st

ceramic margin shoulder firing

A ceramic margin shoulder can be fabricated on the metal

framework after the opaquer firing, if the necessary space

has been provided during finishing. First, isolate the stone die

with IPS Margin Isolating Liquid and then, after drying, with

IPS Classic Ceramic Isolating Liquid. After that, generously

apply the IPS Margin material in the desired tooth shade in

the cervical area in the shape of a drop (i.e. the outer surface

of the ceramic material is given a convex shape) and dry.

incorrect

correct

For aesthetically exacting work, eight Intensive Margin

materials are available. They may either be mixed or applied

alone. Subsequently, the framework with the applied and

dried shoulder material is carefully removed from the die.

Tip

When designing a ceramic shoulder (particularly for

bridges), the Margin material may be applied slightly higher

up in the proximal areas. This will reduce the interdental

shrinkage during the subsequent dentin and incisal firings.

T

950°C

1742°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

949°C

1740°F

➚

T

930°C

1706°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

929°C

1704°F

➚

Important

Please do not forget to consider the different firing

parameters of the 2

nd

margin shoulder firing as

well when using IPS Classic Opaquer or

IPS Lowpaque.

35

2

nd

margin shoulder firing

After the firing, the margin shoulder may have to be slightly

adjusted by grinding. The accuracy of fit (sinter shrinkage)

has to be reestablished by means of a 2

nd

margin shoulder

firing. Use the same Margin materials as for the 1

st

margin

shoulder firing for that purpose.

First, however, isolate the die again with IPS Classic Ceramic

Isolating Liquid. Then, supplement the missing areas by

carefully applying the margin material in the space resulting

from the 1

st

margin shoulder firing, thus providing optimum

accuracy of fit of the ceramic margin shoulder. After that,

complete the margin shoulder, dry, carefully remove the

framework from the die, and place it on the firing tray.

Firing parameters for the 2

nd

margin shoulder firing –

IPS Classic Opaquer

Firing parameters for the 2

nd

margin shoulder firing –

IPS Classic Lowpaque

Important

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

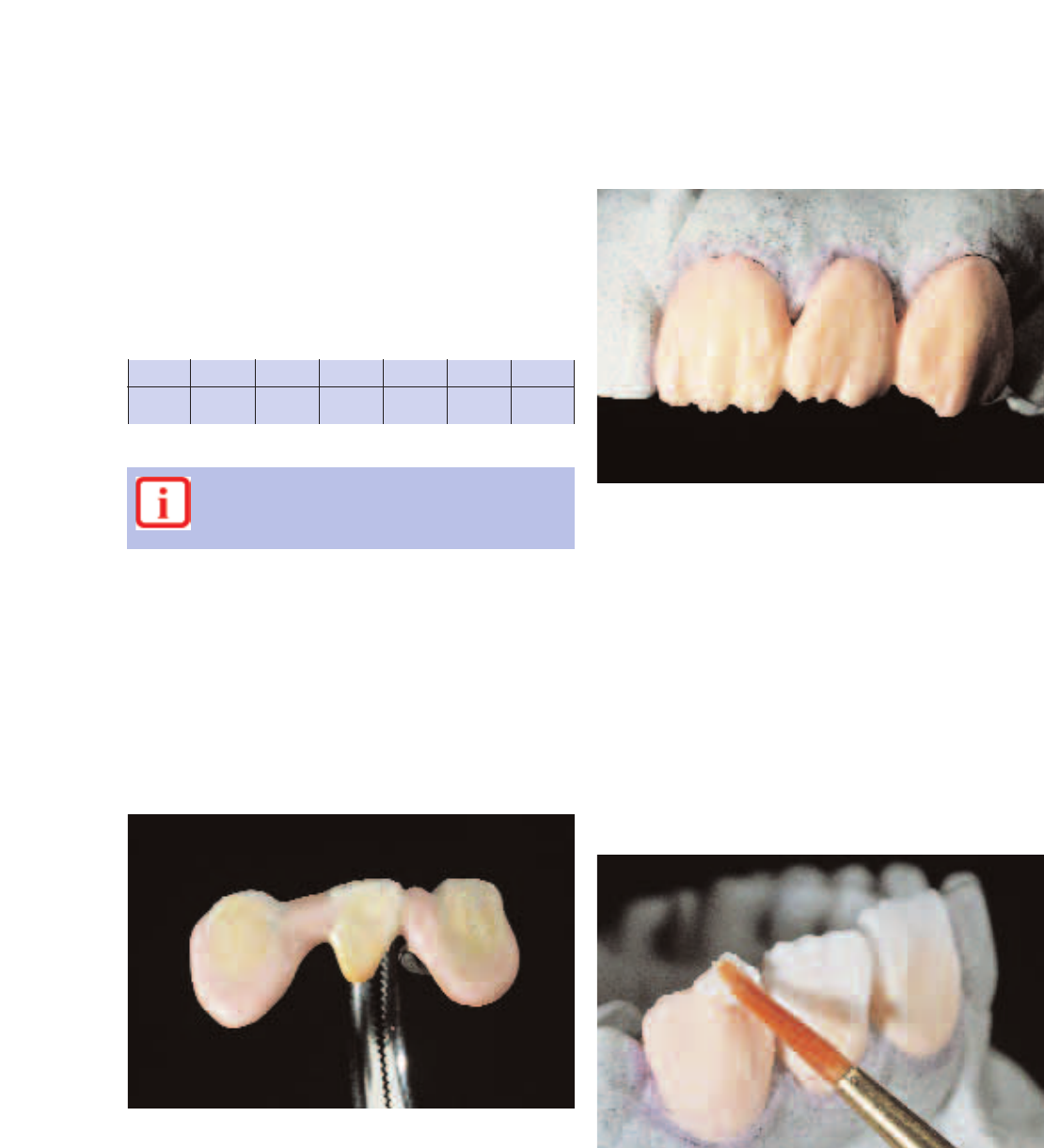

1

st

dentin and incisal firing

Before layering the dentin and incisal materials, sealing the

model is a very important working step. In this way, the

ceramic material is prevented from drying out or sticking to

the model. Use the IPS Classic Model Separator I, followed by

the IPS Classic Ceramic Isolating Liquid to seal the stone die

and the adjoining areas of the model.

A small quantity of IPS Opaque Dentin is applied in the cervical and interdental area………

Isolating the model with the IPS Classic Model Separator I and the IPS Classic Ceramic Isolating Liquid.

……and is slightly roughened to reach a better adaption of the ceramic material on the opaquer surface.

To achieve an optimum bond between the ceramic materials

and the opaquer surface, apply the IPS Opaque Dentin or

Dentin material in small increments, particularly in the

cervical and interdental areas (for bridges) and slightly

roughen it. In this way, the adaption of the Deep Dentin or

Dentin materials on the opaquer surface is enhanced.

T

940°C

1724°F

B

403°C

757°F

S

4 min.

4 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

939°C

1722°F

➚

T

930°C

1706°F

B

403°C

757°F

S

4 min.

4 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

929°C

1704°F

➚

36

Firing parameters for intermediate firing –

IPS Opaque Dentin

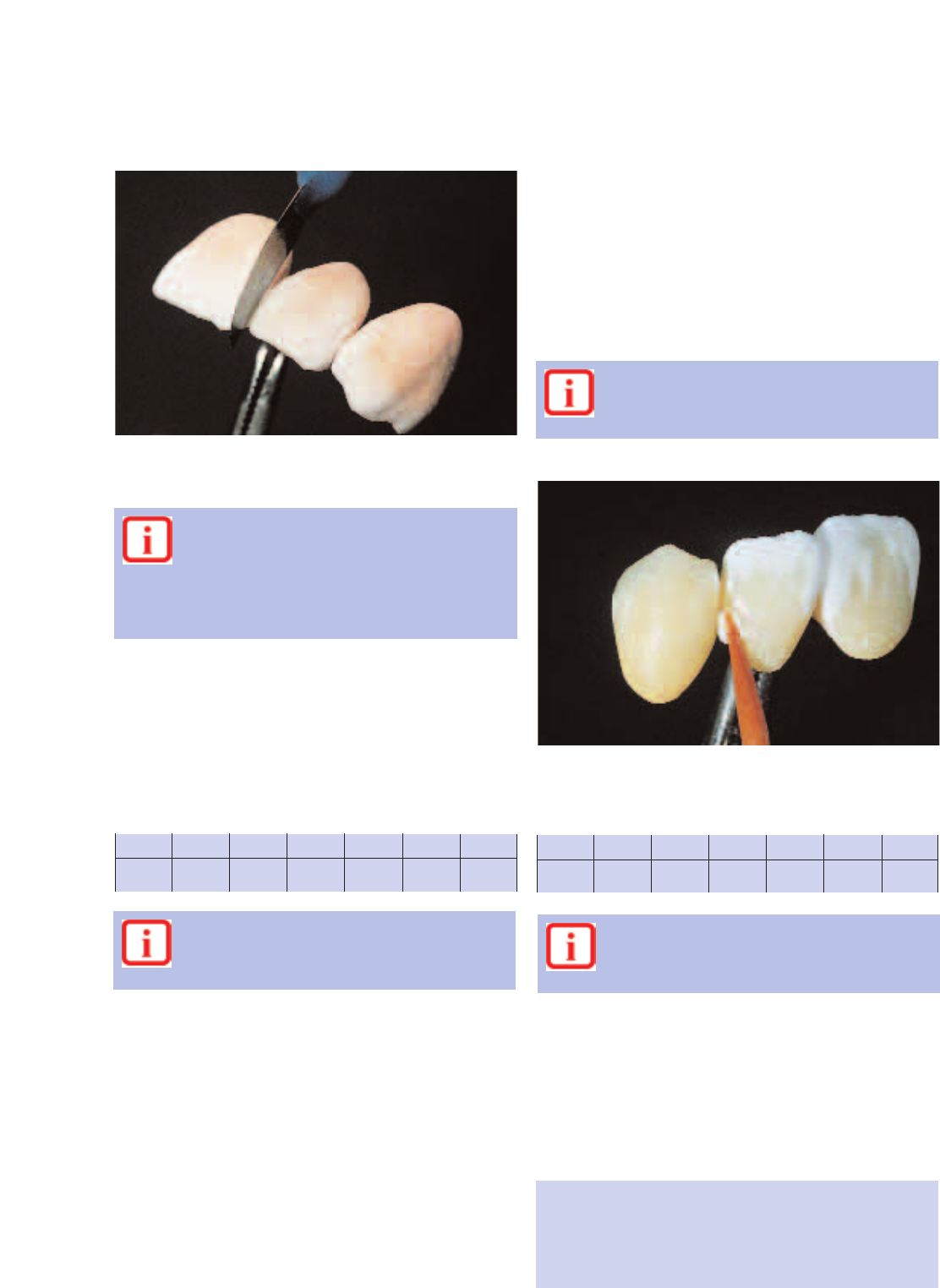

Layered IPS Classic Dentin material, where the mamelon shape is only outlined ...

….then, Incisal and Transparent material is applied in small portions and the anatomical shape is completed

by means of over-contouring.

IPS Opaque Dentin layering to enhance the shade in the cervical area

Important

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

In order to achieve true-to-nature shade effects in areas

where space is limited, IPS Opaque Dentin materials are

used. They are directly applied on the opaquer layer. For

pontics and crowns margins thinning towards the metal,

IPS Opaque Dentin material of the appropriate tooth shade

is applied in the cervical or basal area to enhance the shade.

Next, outline the mamelon area with a layer of Dentin

material. Another option is to contour the full anatomical

shape of the tooth. If this procedure is used, the contoured

crown has to be reduced in the labial, incisal-mesial and

distal areas. The mamelon shape is, once again, only

outlined.

Irrespective of the method used, make sure to provide

adequate space for the subsequent application of the Incisal

and Transparent materials.

Depending on the patient’s situation, an individual and

simple build-up using Mamelon, Effect and Transparent

material in the incisal third can be made to achieve the best

possible aesthetic result.

The palatal fossa of the restoration is covered with

IPS Opaque Dentin orange, the marginal ridges are lined

with Dentin material and finally, they are covered with Incisal

and Transparent material.

Please make sure to overcontour the restoration, so that the

actual tooth shape is achieved after the firing.

Condensing the ceramic surface (after contouring) using a

large, dry brush, makes it more homogeneous, which

prevents the ceramic from pulling away from the margin.

After lifting the bridge from the model supplement the

contact points with dentin and incisal materials. Before

firing, the individual units must be separated using a thin

blade and cutting through the ceramic down to the

opaquer. Moreover, a visual check must be made to make

sure that all areas are properly covered with ceramic prior to

firing.

For large restorations, such as multi-pontic bridges and

implant superstructures, the number of subsequent firings

can be reduced by conducting an intermediate firing using

either IPS Opaque Dentin or dentin material.

T

920°C

1688°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

580°C

1076°F

V

2

919°C

1686°F

➚

37

Clean the restoration thoroughly before the

2

nd

dentin and incisal firing. Polishing beads must

not be used under any circumstances.

Firing parameters for the 2

nd

dentin and incisal firing

Firing parameters for the 1

st

dentin and incisal firing

Important:

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

Important:

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

Once the contact points have been provided, the bridge restorations are separated in the interdental spaces

down to the opaquer using a sharp instrument (e.g. thin scalpel, razor blade).

The proximal areas are supplemented with the same materials used for the 1st dentin and incisal firing and

the restoration is adjusted using Incisal and Transparent materials.

2

nd

dentin and incisal firing

After the first dentin firing, the restoration is finished and

cleaned. After that, any deficient areas are supplemented

with the same materials used for the 1

st

dentin and incisal

firing. The interdental areas and proximal contact points must

be given special attention. Subsequently, conduct the

2

nd

dentin and incisal firing following the firing parameters

indicated below.

The completed restoration is now placed on the firing tray.

Please provide adequate support. The firing tray should be

positioned in the firing chamber only after the head is

completely open and the buzzer has sounded. Fire the

restorations with the following parameters:

–Provide adequate support for bridges on the

firing tray.

–Position the firing tray in the furnace only after the head

has completed its opening sequence (once the buzzer has

sounded).

Tip:

Before completion of the restoration, the roughly fired

restoration can be tried in to make sure that the shade,

shape and function of the layered restoration corresponds

with the patient's individual situation.

T

920°C

1688°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

580°C

1076°F

V

2

919°C

1686°F

➚

T

910°C

1670°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

580°C

1076°F

V

2

909°C

1668°F

➚

38

Providing a true-to-nature surface texture including growth lines and convex/concave areas.

Preparing the restoration for glaze firing

Prepare the restoration for glaze firing by providing surface

textures, such as growth lines and convex/concave areas.

Stains and characterization firing

To apply shade corrections and individual characterizations, a

wide shade range is available.

Shade corrections with IPS Shade, IPS Shade V and

IPS Stains-P

These stains can be fired in a separate stains firing. Small

shade adjustments and individualized characterizations can

be fired in a glaze firing.

IPS Shade and IPS Shade V

These dentin stains are used for subsequent

shade adjustments of IPS Classic

restorations. They are used for

surface staining and for internal

shading of the layering

materials.

Depending on the working habits of the user, the prominent

areas can be prepolished using silicone polishers.

Tip:

Natural surface textures may be made visible with the help

of gold and/or silver dust.

Subsequently, the restoration is cleaned with steam so that

the surface is free of dirt and grease. Make sure that the

entire gold/silver dust is removed.

Note:

Finishing ceramic restorations results in grinding dust.

Avoid inhalation. Use an appropriate suction equipment or

protective mask.

Note

– If too much IPS Shade Material is added, the

structure of the material can change (e. g.

distribution of grain size), which has a negative

effect on the ceramic construction.

–Clean the restoration thoroughly before the stains and

characterization firing. Polishing beads must not be used

under any circumstances.

Remove the desired amount of IPS Shade/ IPS Shade V from

the syringe and mix with IPS Classic Glazing and Staining

liquid to the desired consistency.

Apply IPS Shade/ IPS Shade V in the cervical area and the

body of the restoration. Check the shade adjustment

achieved with the help of the shade guide.

Avoid pooling or applying too thick of a layer. More

intensive shades are achieved by several staining procedures,

not by applying thicker layers. If the desired shade is not

achieved, repeat the stain firing using the same firing

parameters. If only minor shade adjustments are required,

they may be done during the glaze firing.

Firing parameters for the stain and characterization

firing – IPS Shade / IPS Shade V

Important

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

T

900°C

1652°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

0°C

0°F

V

2

0°C

0°F

➚

39

IPS Stains-P

Remove the desired amount of

IPS Stains from the syringe and mix

with IPS Classic Glazing and

Staining liquid to the desired

consistency.

Apply individualized

characterizations with

IPS Stains-P on the ceramic

surface, e. g. discoloration and enamel stains.

Note

If too much IPS Stains-P Material is added, the

structure of the material can change (e. g.

distribution of grain size), which has negative

effects on the ceramic construction.

Important

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

Important

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

Firing parameters for the stains firing – IPS Stains-P

Glaze firing

For the glaze firing, you have several options, depending on

the desired working procedure:

– Glaze firing without IPS Classic Glazing material for a true-

to-nature, silky-mat gloss.

– Glaze firing with IPS Classic Glazing material for a high

gloss.

The following basic rule applies:

The longer the holding time, the higher is the gloss.

Method 1

Glaze firing without glazing material

Slightly wet the restoration using IPS Classic Glazing and

Staining liquid and apply shade adjustments and/or

individualized characterizations. Position the restoration on

the honey-combed firing try and fire. If the glaze firing is

conducted without glazing materials, the stains should not

cover too large an area. After firing, the gloss of the

restoration may be adjusted to meet the patient's individual

requirements by polishing with rubber polishers, felt wheels,

and pumice.

Method 2

Glaze firing with glazing material

Remove IPS Classic Glazing material

from its container and mix

thoroughly. If another

consistency is desired,

the material can be slightly diluted with Classic Glazing and

Staining liquid. After that, apply glazing material in the usual

manner using a brush. Avoid pooling or applying too thick of

a layer.

Firing parameters for glaze firing without glazing

material

Apply minor shade adjustments on the applied

glazing material using IPS Shade, IPS Shade V and

IPS Stains-P.

T

900°C

1652°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

0°C

0°F

V

2

0°C

0°F

➚

T

920°C

1688°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

0°C

0°F

V

2

0°C

0°F

➚

40

Corrective firings

After the try-in of a restoration, minor shape adjustments,

e.g. contact points, pontic rests, margin shoulder

adjustments, may be necessary. To meet these different

requirements a low-fusing correction powder with medium

incisal opacity is available.

Depending on the individual preference, the IPS Classic

Correction Powder can be processed using two different

methods.

Method 1 (dentin / incisal adjustments)

Mix IPS Classic Correction Powder with any dentin or incisal

material in a 1:1 ratio and then mix with the desired build-up

liquid. Make adjustments and fire.

Firing parameters for the corrective firing with

IPS Classic Correction Powder (1:1)

Firing parameters for glaze firing with glazing material

Apply glazing material in the usual manner using a brush.

Finally, check the shade of the completed restoration with

the help of the corresponding shade tab.

Important

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

T

900°C

1652°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1–2 min.

1–2 min.

V

1

0°C

0°F

V

2

0°C

0°F

➚

Important

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

T

810°C

1490°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

420°C

788°F

V

2

809°C

1488°F

➚

41

Method 2 (contact areas)

Mix IPS Classic Correction Powder alone with the desired

build-up liquid. Make adjustments and fire.

Firing parameters for the corrective firing with

IPS Classic Correction Powder (alone)

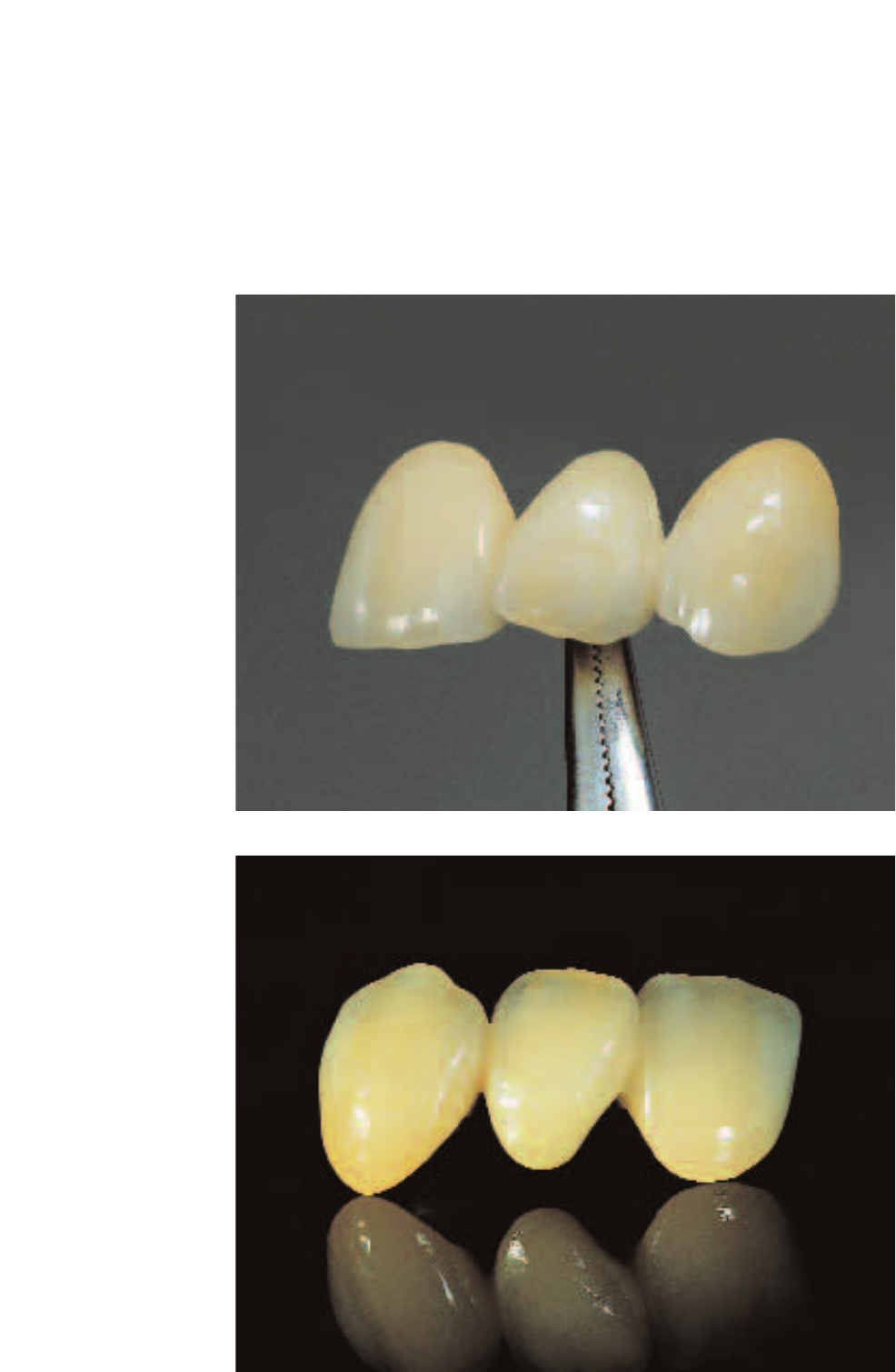

Completely fired IPS Classic bridge on the model.

The result:

Important

If furnaces of other manufacturers are used, these

parameters have to be adjusted accordingly.

T

690°C

1274°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

0.5 min.

0.5 min.

V

1

420°C

788°F

V

2

689°C

1272.2°F

➚

42

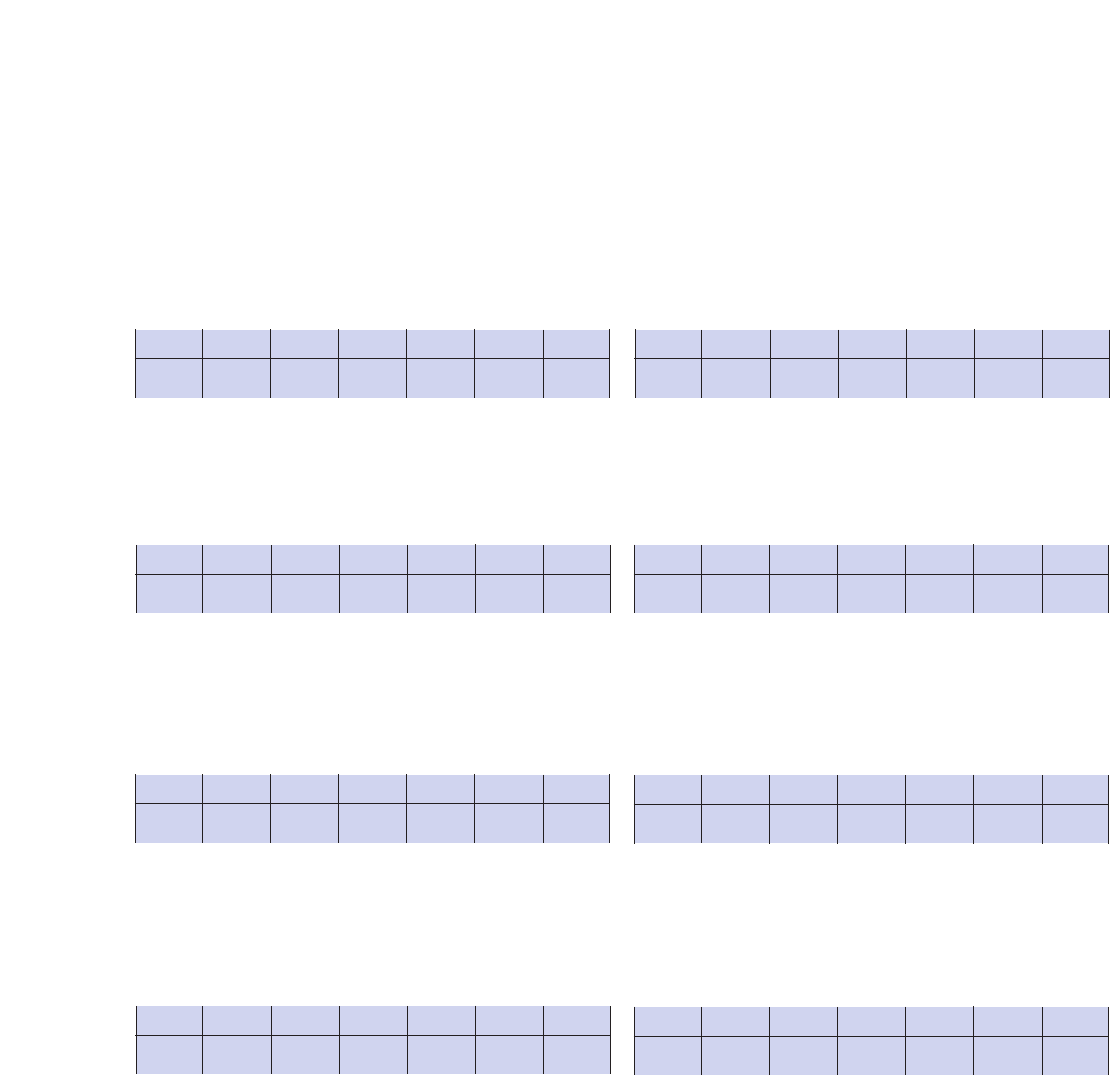

Classic – Firing parameters

IPS

Firing parameters for the 1

st

opaquer firing (wash

firing) – IPS Classic Opaquer

Firing parameters for the 1

st

opaquer firing (wash

firing) –IPS Lowpaque

Firing parameters for the 2

nd

opaquer firing –

IPS Classic Opaquer

Firing parameters for the 2

nd

opaquer firing –

IPS Lowpaque

Firing parameters for the 1

st

margin shoulder firing –

IPS Classic Opaquer

Firing parameters for the 1

st

margin shoulder firing –

IPS Lowpaque

Firing parameters for the 2

nd

margin shoulder firing -

IPS Classic Opaquer

Firing parameters for the 2

nd

margin shoulder firing –

IPS Classic Lowpaque

Method A – IPS Classic Opaquer Method B – IPS Lowpaque

T

980°C

1796°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

979°C

1794°F

➚

T

920°C

1688°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

450°C

842°F

V

2

919°C

1686°F

➚

T

970°C

1778°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

969°C

1776°F

➚

T

910 °C

1670 °F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

450°C

842°F

V

2

909°C

1668°F

➚

T

950°C

1742°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

949°C

1740°F

➚

T

930°C

1706°F

B

403°C

757°F

S

6 min.

6 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

929°C

1704°F

➚

T

940°C

1724°F

B

403°C

757°F

S

4 min.

4 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

939°C

1722°F

➚

T

930°C

1706°F

B

403°C

757°F

S

4 min.

4 min.

t

80°C

144°F

H

1 min.

1 min.

V

1

550°C

1022°F

V

2

929°C

1704°F

➚

43

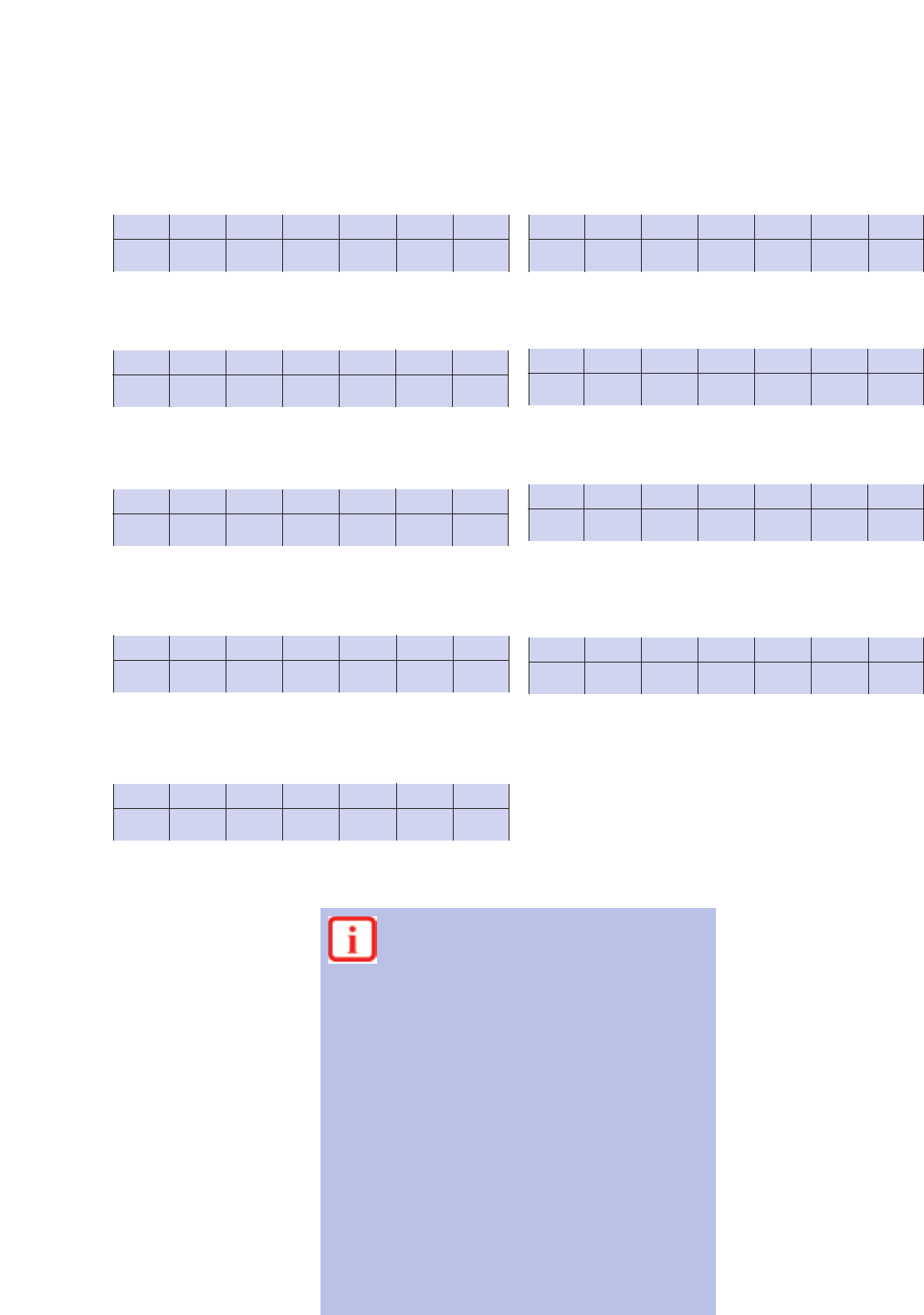

These firing parameters represent standard values

applicable to the P100, P 200, PX 1 and EP 600

Combi furnaces from Ivoclar Vivadent. The

temperatures indicated also apply to furnaces of older

generations, such as the P20, P80, P90 and P95. If one of

these furnaces is used, however, the temperatures may

deviate by ± 10 °C/18 °F, depending on the age and type of

the heating muffle.

If a non-Ivoclar Vivadent furnace is used, temperature

corrections may be necessary.

Regional differences in the power supply or the operation

of several electronic devices on the same circuit may make

adjustments of the firing temperatures necessary.

Ceramic furnaces of other manufacturers often feature

opening mechanisms different from that of Ivoclar Vivadent

furnaces. Therefore, the firing conditions may also differ.

Make sure that these varying firing conditions are taken

into account when working with IPS Classic.

Remember to calibrate your furnace regularly.

Firing parameters for IPS Opaque Dentin

(intermediate firing)

Firing parameters for the 1

st

dentin and incisal firing

Firing parameters for the stains and characterization

firing – IPS Shade / IPS Shade V

Firing parameters for the stains firing – IPS Stains-P

Firing parameters for glaze firing without glazing

material

Firing parameters for glaze firing with glazing material

Firing parameters for the corrective firing –

IPS Classic Correction Powder (1:1)

Firing parameters for the corrective firing –

IPS Classic Correction Powder (alone)

Firing parameters for the 2

nd

dentin and incisal firing

T

920°C

1688°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

580°C

1076°F

V

2

919°C

1686°F

➚

T

920°C

1688°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

580°C

1076°F

V

2

919°C

1686°F

➚

T

910°C

1670°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

580°C

1076°F

V

2

909°C

1668°F

➚

T

900°C

1652°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

0°C

0°F

V

2

0°C

0°F

➚

T

900°C

1652°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

0°C

0°F

V

2

0°C

0°F

➚

T

920°C

1688°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

0°C

0°F

V

2

0°C

0°F

➚

T

900°C

1652°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1–2 min.

1–2 min.

V

1

0°C

0°F

V

2

0°C

0°F

➚

T

810°C

1490°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

1 min.

1 min.

V

1

420°C

788°F

V

2

809°C

1488°F

➚

T

690°C

1274°F

B

403°C

757°F

S

4 min.

4 min.

t

60 °C

108°F

H

0.5 min.

0.5 min.

V

1

420°C

788°F

V

2

689°C

1272.2°F

➚

44

Classic –

Materials combination table

IPS

white

yellow

light brown

grey

dark brown

Chromascop shades

Assortment Materials / Shade groups Special materials

IPS Classic Opaquer (O) 110 120 130 140 210 220 230 240 310 320 330 340 410 420 430 440 510 520 530 540

Intensive Opaquer (IO) white, orange, brown, violet, grey

Dentin (D) 110 120 130 140 210 220 230 240 310 320 330 340 410 420 430 440 510 520 530 540

Intensive Dentin (ID) neutral, white, yellow honey, light brown, dark brown, pink, grey, blue, clear pink, red pink

Incisal (S) S3 S1 S1 S1 S1 S2 S2 S2 S5 S5 S5 S2 S4 S4 S1 S4 S4 S2 S5 S3

Opal Incisal (OS) OS3 OS1 OS1 OS1 OS1 OS2 OS2 OS2 OS5 OS5 OS5 OS2 OS4 OS4 OS1 OS4 OS4 OS2 OS5 OS3

Transparent (T) neutral, reddish, greyish, transparent

IPS Opaque Dentin Opaque Dentin (Op.D.) – 120 130 140 210 220 230 240 310 320 – – 410 420 430 440 510 – – –

IPS Margin Margin (M) M1 M2 M2 M3 M3 M3 M4 M4 M6 M6 M5 M5 M9 M9 M9 M9 M9 M7 M7 M8

Intensive Margin (M) M10, M11, M12, M13, M14

IPS Impulse Occlusal Dentin (Oc.D.) brown, yellow, orange

Mamelon material (MM) MM1, MM2, MM3, MM4,MM orange

Incisal (S) yellow-grey, grey

Transparent (T) yellow-grey, grey, blue

Molar Incisal (MS) MS

Incisal Edge material (IS) light yellow, yellow

IPS Shade Dentin Stains 110 120 130 140 210 220 230 240 310 320 330 340 410 420 430 440 510 520 530 540

IPS Stains-P Characterization Stains white, orange, bamboo, caramel brown, copper brown, cork brown, mahogany, azure, black yellow, red, blue

45

A–D shades

Assortment Materials / Shade groups ABCDSpecial materials

IPS Classic V Opaquer (O) A1 A2 A3 A3.5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4

Intensive Opaquer (IO) IO-A IO-B IO-C IO-A/IO-B IO-white, IO-violet

Dentin (D) A1 A2 A3 A3.5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4

Incisal (S) S1 S2 S2 S4 S4 S1 S2 S3 S4 S2 S2 S3 S4 S1 S2 S3

Transparent (T) clear, neutral

IPS Opaque Dentin V Opaque Dentin (Op.D.) A1 A2 A3 A3.5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4

Opaque Dentin (Op.D.) yellow, orange, brown

IPS Margin V Margin Material (M) A1 A2 A3 A3.5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4

Intensive (M) yellow, orange, brown

IPS Impulse Occlusal Dentin (Oc.D.) orange yellow brown orange, yellow

Mamelon Material (MM) MM1, MM2, MM3, MM4, MM orange

Incisal (S) yellow-grey, grey

Transparent (T) yellow-grey, grey, blue

Molar Incisal (MS) MS

Incisal Edge material (IS) light yellow, yellow

IPS Shade V Dentin Stains A1 A2 A3 A3.5 A4 B1 B2 B3 B4 C1 C2 C3 C4 D2 D3 D4

IPS Stains-P Characterization Stains white, orange, bamboo, caramel brown, copper brown, cork brown, mahogany, azure, black basic yellow, basic

red, basic blue

46

Classic – A sound concept always

reaps success!

IPS

47

Ivoclar Vivadent AG

Bendererstrasse 2

FL-9494 Schaan

Liechtenstein

Tel. +423 235 35 35

Fax +423 235 33 60

www.ivoclarvivadent.com

Ivoclar Vivadent Pty. Ltd.

1 – 5 Overseas Drive

P. O. Box 367

Noble Park, Vic. 3174

Australia

Tel. +61 3 979 595 99

Fax +61 3 979 596 45

Ivoclar Vivadent Ltda.

Rua Maestro João Gomes de

Araújo 50; Salas 92/94

Sao Paulo, CEP 02332-020

Brasil

Tel. +55 11 69 59 89 77

Fax +55 11 69 71 17 50

Ivoclar Vivadent, Inc.

23 Hannover Drive

St. Catharines, Ont. L2W 1A3

Canada

Tel. +1 800 263 8182

Fax +1 905 988 5411

Ivoclar Vivadent Marketing

Ltd.

Calle 134 No. 13-83, Of. 520

Bogotá

Colombia

Tel. +57 1 627 33 99

Fax +57 1 633 16 63

Ivoclar Vivadent SAS

B.P. 118

F-74410 Saint-Jorioz

France

Tel. +33 450 88 64 00

Fax +33 450 68 91 52

Ivoclar Vivadent GmbH

Dr. Adolf-Schneider-Str. 2

D-73479 Ellwangen, Jagst

Germany

Tel. +49 (0) 79 61 / 8 89-0

Fax +49 (0) 79 61 / 63 26

Ivoclar Vivadent UK Limited

Meridian South

Leicester

LE19 1WY

Great Britain

Tel. +44 116 265 40 55

Fax +44 116 265 40 57

Ivoclar Vivadent s.r.l.

Via dell’Industria 16

I-39025 Naturno (BZ)

Italy

Tel. +39 0473 67 01 11

Fax +39 0473 66 77 80

Ivoclar Vivadent S.A. de C.V.

Av. Mazatlán No. 61, Piso 2

Col. Condesa

06170 México, D.F.

Mexico

Tel. +52 (55) 55 53 00 38

Fax +52 (55) 55 53 14 26

Ivoclar Vivadent Ltd

12 Omega St, Albany

PO Box 5243 Wellesley St

Auckland, New Zealand

Tel. +64 9 914 9999

Fax +64 9 914 9990

Ivoclar Vivadent Polska Sp.

z.o.o.

ul. Jana Pawla II 78

PL-01-501 Warszawa

Poland

Tel. +48 22 635 54 96

Fax +48 22 635 54 69

Ivoclar Vivadent S.A.

c/Emilio Muñoz, 15

Esquina c/Albarracín

E-28037 Madrid

Spain

Tel. +34 91 513 10 08

Fax +34 91 552 64 07

Ivoclar Vivadent AB

Dalvägen 16

S-169 56 Solna

Sweden

Tel. +46 8 514 93 930

Fax +46 8 514 93 940

Ivoclar Vivadent, Inc.

175 Pineview Drive

Amherst, N.Y. 14228

USA

Tel. +1 800 533 6825

Fax +1 716 691 2285

Ivoclar Vivadent – worldwide

Date information prepared:

05/2003

These materials have been developed solely for use

in dentistry. Processing should be carried out

according to the Instructions for Use. Liability cannot

be accepted for damages resulting from failure to

observe the Instructions or the stipulated area of

application. The user is responsible for testing the

material for its suitability for any purpose not

explicitly stated in the Instructions. This also applies

if the materials are mixed or processed with

products of other manufacturers.

Descriptions and data constitute no warranty of

attributes and are not binding.

Printed in Liechtenstein

© Ivoclar Vivadent AG, Schaan / Liechtenstein

574376/0603/e/2/BVD