SAFETY

STUDY APPLICABLE OSHA AND OTHER SAFETY REQUIREMENTS BEFORE

FOLLOWING THESE INSTRUCTIONS.

The installation of metal roof systems is a dangerous procedure and should be supervised by trained knowl-

edgeable erectors. USE EXTREME CARE WHILE INSTALLING ROOF PANELS. It is not possible for Metal

Sales to be aware of all the possible job site situations that could cause an unsafe condition to exist. The erec-

tor of the roof system is responsible for reading these instructions and determining the safest way to install the

roof system.

These instructions are provided only as a guide to show a knowledgeable, trained erector the correct part

placement one to another. If following any of the installation steps would endanger a worker, the erector should

stop work and decide upon a corrective action.

Provide required safety railing, netting, or safety lines for crew members working on the roof.

Do not use the roof panel as a walking platform. The roof panels will not withstand the weight of a person

standing at the edge of the panel.

Do not stand on the roof panel until the panels have been attached.

The application and detail drawings in this manual are strictly for illustration purposes and may not be appli-

cable to all building designs or product installations. All projects should conform to applicable building codes

for that particular area. It is recommended to follow all building regulations and standard industry practices.

Metal Sales Manufacturing Corporation is not responsible for the performance of the roof system if it is not

installed in accordance with the suggested instructions referenced in this installation manual or in the product

overview. (See Product Manual or Product Technical Literature). If there is a conict between this manual and

the actual erection drawings, the erection drawings are to take precedence.

Prior to ordering and installing materials, all dimensions should be veried by eld measurements.

Metal Sales reserves the right to modify, without notice, any details, recommendations or suggestions. Any

questions you may have regarding proper installation of the roong system should be directed to your Metal

Sales representative, see pages 2 and 3.

Consult Metal Sales for any additional information not outlined in this manual.

This manual is designed to be utilized as a guide when installing Post Frame and Residential roong systems.

It is the responsibility of the erector to ensure the safe installation of this product system.

Classic Rib

®

Install Guide

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

2

CLASSIC RIB

®

For more than 55 years, Metal Sales Manufacturing Corporation has earned a reputation

as the premier provider of innovative metal building components and accessories.

We’ve backed this reputation with the industry’s largest professional sales and

services team. We offer a full line of exceptional quality metal roof and wall panels

for agricultural, commercial, architectural, industrial and residential projects of

every shape and size, new construction or retro-t.

15

14

5,10

1

9

8

13

4

11

18

6

17

3

12

7

19

2

16

20

21

Branch Territory Map

NOTE: Shaded areas represent regions served by each location.

*

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

3

CLASSIC RIB

®

1. DENVER BRANCH

7990 E. I-25 Frontage Road

Longmont, CO 80504

303.702.5440

800.289.7663

800.289.1617 Fax

2. JACKSONVILLE BRANCH

7110 Stuart Avenue

Jacksonville, FL 32254

904.783.3660

800.394.4419

904.783.9175 Fax

800.413.3292 Fax

3. JEFFERSON BRANCH

352 East Erie Street

Jefferson, OH 44047

440.576.9070

800.321.5833

440.576.9242 Fax

800.233.5719 Fax

4. INDEPENDENCE BRANCH

1306 South Powell Road

Independence, MO 64057

816.796.0900

800.747.0012

816.796.0906 Fax

5. SELLERSBURG BRANCH

7800 State Road 60

Sellersburg, IN 47172

812.246.1866

800.999.7777

812.246.0893 Fax

800.477.9318 Fax

6. ROGERS BRANCH

22651 Industrial Boulevard

Rogers, MN 55374

763.428.8080

800.328.9316

763.428.8525 Fax

800.938.9119 Fax

7. NASHVILLE BRANCH

4314 Hurricane Creek Boulevard

Antioch, TN 37013

615.641.7100

800.251.8508

615.641.7118 Fax

800.419.4372 Fax

8. SPOKANE BRANCH

East 2727 Trent Avenue

Spokane, WA 99202

509.536.6000

800.572.6565

509.534.4427 Fax

9. SEATTLE BRANCH

20213 84th Avenue, South

Kent, WA 98032

253.872.5750

800.431.3470 (Outside WA)

800.742.7900 (Inside WA)

253.872.2008 Fax

10. NEW ALBANY BRANCH

999 Park Place

New Albany, IN 47150

812.944.2733

812.944.1418 Fax

11. ROCK ISLAND BRANCH

8111 West 29th Street

Rock Island, IL 61201

309.787.1200

800.747.1206

309.787.1833 Fax

12. DEER LAKE BRANCH

29 Pinedale Industrial Road

Orwigsburg, PA 17961

570.366.2020

800.544.2577

570.366.1648 Fax

800.544.2574 Fax

13. TEMPLE BRANCH

3838 North General Bruce Drive

Temple, TX 76501

254.791.6650

800.543.4415

254.791.6655 Fax

800.543.4473 Fax

14. WOODLAND BRANCH

1326 Paddock Place

Woodland, CA 95776

530.668.5690

800.759.6019

530.668.0901 Fax

15. FONTANA BRANCH

14213 Whittram Avenue

Fontana, CA 92335

909.829.8618

800.782.7953

909.829.9083 Fax

16. ANCHORAGE BRANCH

4637 Old Seward Highway

Anchorage, AK 99503

907.646.7663

866.640.7663

907.646.7664 Fax

17. BAY CITY BRANCH

5209 Mackinaw Road

Bay City, MI 48706

989.686.5879

888.777.7640

989.686.5870 Fax

888.777.0112 Fax

18. DETROIT LAKES BRANCH

1435 Egret Avenue

Detroit Lakes, MN 56501

218.847.2988

888.594.1394

218.847.4835 Fax

888.594.1454 Fax

19. MOCKSVILLE BRANCH

188 Quality Drive

Mocksville, NC 27028

336.751.6381

800.228.6119

336.751.6301 Fax

800.228.7916 Fax

20. FORT SMITH BRANCH

7510 Ball Road

Fort Smith, AR 72908

479.646.1176

877.452.3915

479.646.5204 Fax

21. SIOUX FALLS BRANCH

2700 West 3rd Street, Suite 4

Sioux Falls, SD 57104

605.335.2745

888.299.0024

TECHNICAL SERVICES

545 South 3rd Street, Suite 200

Louisville, KY 40202

502.855.4300

800.406.7387

502.855.4290 Fax

800.944.6884 Fax

TECHNICAL SUPPORT

Branch Locations

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

4

CLASSIC RIB

®

PAGE NO.

General Information

Important Information ................................................................................1

Metal Sales' Locations ..............................................................................2

Customer Service .....................................................................................3

Panel Information

Panel Overview .........................................................................................6

Testing and Approvals ...............................................................................6

Fastening Patterns ....................................................................................6

Panel Lap Detail .......................................................................................7

Section Properties ....................................................................................7

Classic Rib Fastener Installation .......................................................................8

Post Frame Flashing Profiles .......................................................................9-11

Residential Flashing Profiles ..........................................................................12

Accessory Profiles ...........................................................................................13

Handling Material

Receiving Material ..................................................................................14

General Handling ....................................................................................14

Mechanical Handling ..............................................................................14

Manual Handling .....................................................................................15

Storage

General ...................................................................................................16

Foot Traffic .............................................................................................16

Required Tools .........................................................................................16

Design / Installation Considerations

General ....................................................................................................17

Condition of Substructure ........................................................................17

Field Cutting and Touch-Up

Field Cutting .............................................................................................18

Touch-Up Paint ........................................................................................18

Ventilation ................................................................................................18

Fastener Selection Guide ................................................................................19

Installation Overview ........................................................................................20

Post Frame Panel Installation

Installing Inside Closures (Step 1) ...........................................................21

Installing First Panel (Step 2) ...................................................................21

Installing Endlap Panel (Step 3) ..............................................................22

Installing Sidelap Panel (Step 4)..............................................................22

14" Universal Ridge Detail .......................................................................23

Low Profile Ridge Vent ............................................................................23

Outside Corner Detail ..............................................................................23

Inside Corner Detail .................................................................................23

Gable Trim Detail .....................................................................................24

Rake Trim Detail ......................................................................................24

Universal Sidewall Detail .........................................................................24

Universal Endwall Detail ..........................................................................24

Eave Molding Detail .................................................................................25

Universal Gambrel Detail .........................................................................25

TABLE OF CONTENTS

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

5

CLASSIC RIB

®

PAGE NO.

TABLE OF CONTENTS (cont.)

Angle Base Detail ....................................................................................25

Double Angle Detail .................................................................................25

Drip Cap Detail ........................................................................................26

Base Molding Detail .................................................................................26

Cannonball Track Cover Detail ................................................................26

National Track Cover Detail .....................................................................26

Door Jamb Molding Detail .......................................................................27

Mini-Angle - U-Flashing Detail .................................................................27

Post Trim Detail .......................................................................................27

Door Post Trim Detail ...............................................................................27

Overhead Door Trim Detail ......................................................................28

Soffit Detail ..............................................................................................28

12" Soffit Detail ........................................................................................28

24" Soffit Detail ........................................................................................28

Installation Overview ........................................................................................29

Residential Panel Installation

Installing Inside Closures (Step 1) ...........................................................30

Installing First Panel (Step 2) ...................................................................30

Installing Second Panel (Step 3) .............................................................31

Installing Second Eave Panel (Step 4) ....................................................31

14" Universal Ridge Detail .......................................................................32

Ridge / Hip Cover Detail ..........................................................................32

Vented Ridge Detail .................................................................................32

Gable Trim Detail .....................................................................................32

Eave Detail ..............................................................................................33

Gutter Detail .............................................................................................33

Valley Detail .............................................................................................33

Pitch Break Detail ....................................................................................33

Chimney / Cricket Detail ..........................................................................34

Roof Penetration Detail ............................................................................34

Care and Maintenance .....................................................................................35

Notes ............................................................................................................36,37

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

6

CLASSIC RIB

®

}

Finishes: MS Colorfast45

®

, ColorFit40™, Versa20 and Acrylic Coated Galvalume

®

}

Corrosion Protection: AZ55 per ASTM A 792 for unpainted Galvalume

®

AZ50 per ASTM A 792 for painted Galvalume

®

AZ35 per ASTM A 792 for painted Galvalume

®

(ColorFit40 only)

G60, G90 or G100 per ASTM A 653 for Galvanized

}

Gauges: 29 ga and 26 ga standard; 24 ga optional

}

Panel Length: Minimum: 5'-0"; Maximum: 45'-0" recommended

}

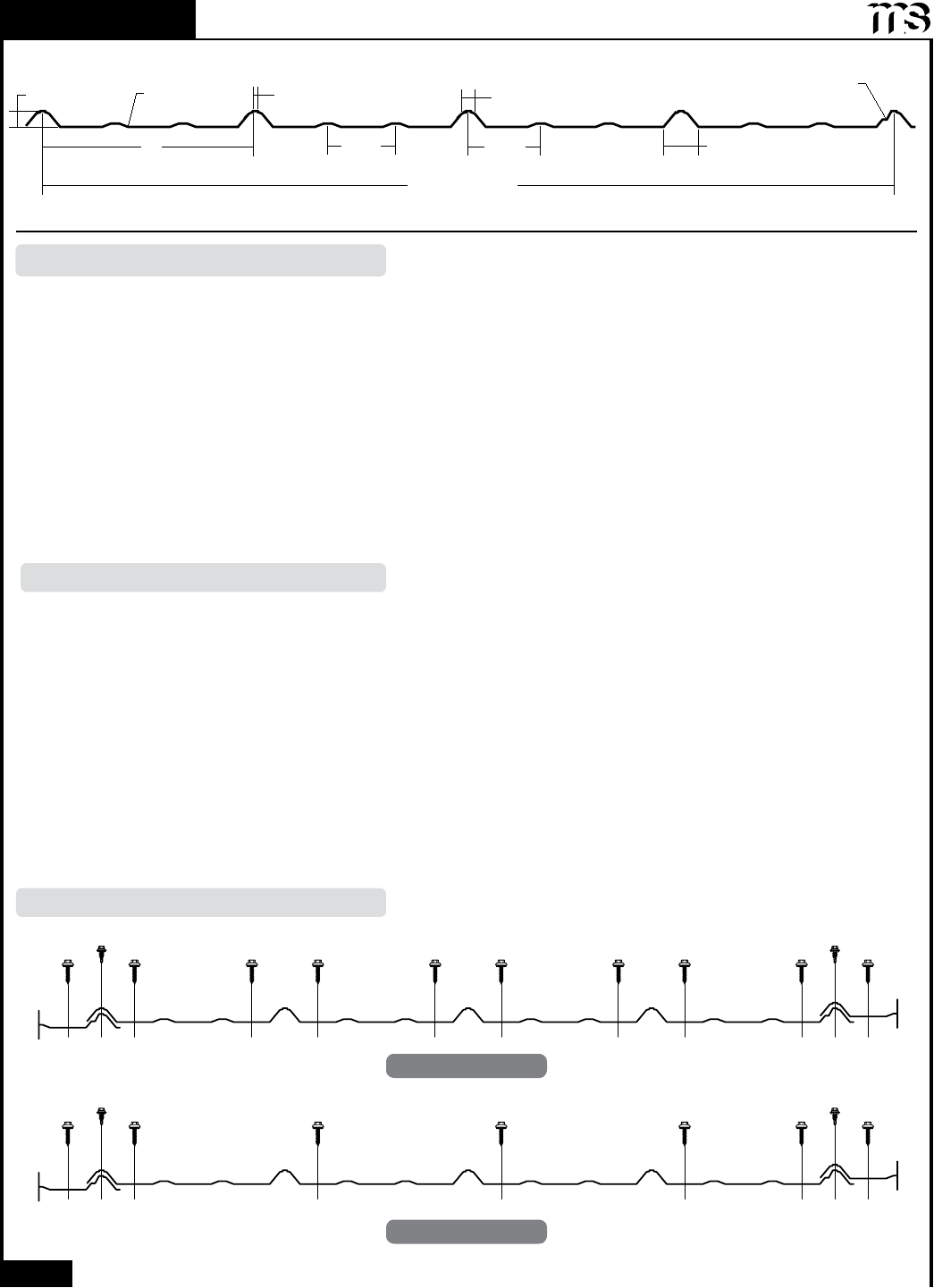

Prole: 36" panel coverage, 3/4" rib height

}

Prole: Exposed fastened panel, low prole, bell-top trapezoidal rib on 9" centers

}

Minimum roof slope: 3:12

PANEL OVERVIEW

}

UL 2218 Impact Resistance - Class 4

}

UL 790 Fire Resistance Rating - Class A, per building code

}

UL 263 Fire Resistance Rating - per assembly

}

UL 580 Uplift Resistance - Class 90 Constructions: #560, 584

}

ASTM E 455, Diaphragm Capacity

}

Texas Wind Storm - Evaluation RC-161

}

2017 FBC Approvals - FL9482.2, FL9482.3, 10999.3, FL 10999.4, FL14645.5, FL14645.8,

FL14645.9, FL14645.10 and FL14645.11

}

Miami-Dade County, Florida NOA 16-0218.02, expires 8/24/2021

}

ICC Evaluation Report, ESR-2385

TESTING AND APPROVALS

36" Coverage

Anti-Siphon Groove

9"

3

/

4

"

3

/

8

"

3

1

/

8

"

2

3

/

4

"

5

/

8

"

C

1

3

/

4

"

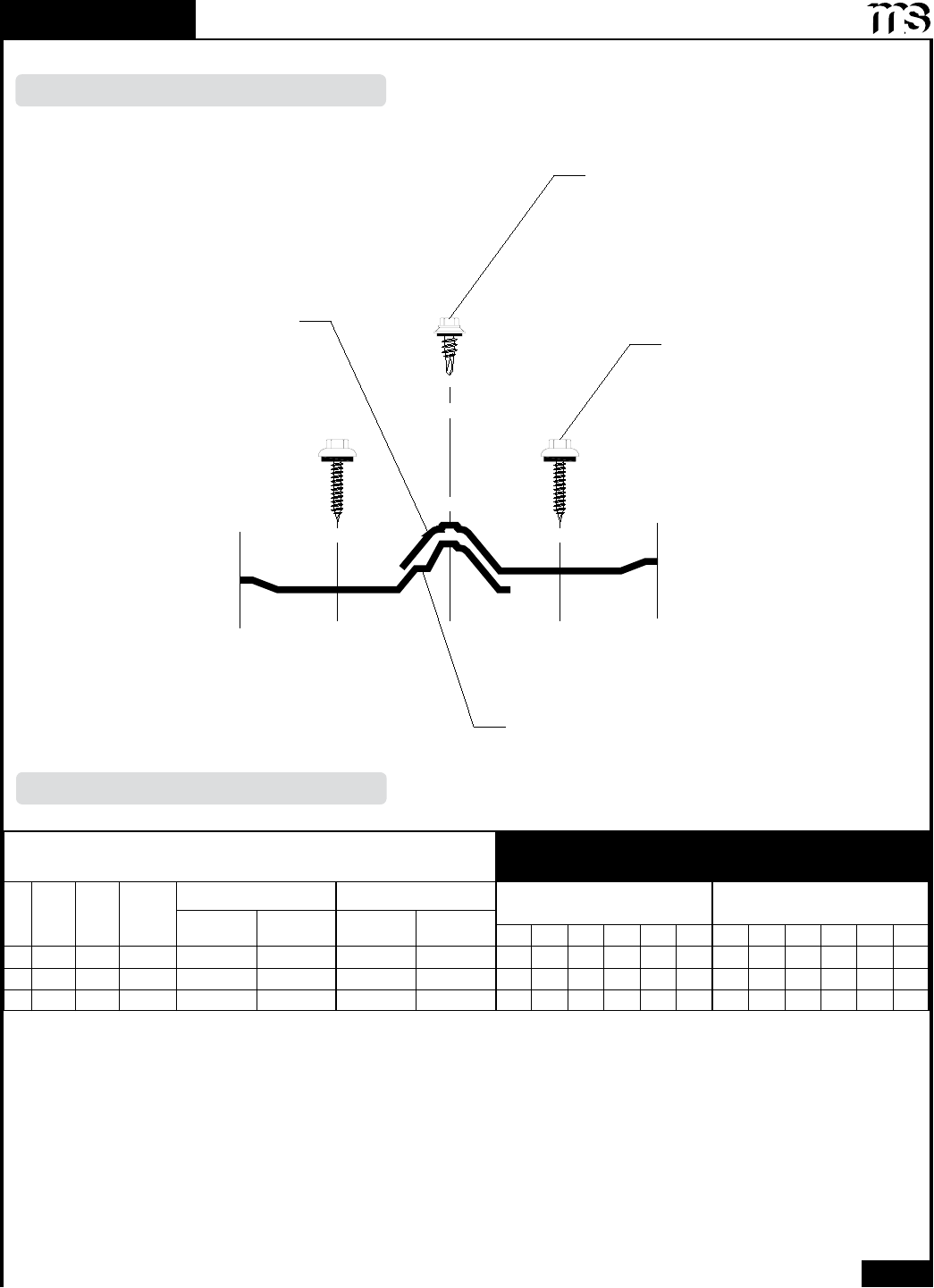

PANEL INFORMATION

Field of Panel

End of Panel

FASTENING PATTERNS

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

7

CLASSIC RIB

®

PANEL INFORMATION

Anti-Siphon Groove

Classic Rib Panel

1

/

4

"-14 x

7

/

8

" Stitch Screw

(for roof only)

#10-14 Woodscrew

PANEL LAP DETAIL

SECTION PROPERTIES

1. TheoreticalsectionpropertieshavebeencalculatedperAISI2016'NorthAmericanSpecicationfortheDesignofCold-FormedSteel

StructuralMembers'.IxxandSxxareeffectivesectionpropertiesfordeectionandbending.

2. AllowableloadiscalculatedinaccordancewithAISI2016specicationsconsideringbending,shear,combinedbendingandshearand

deection.Allowableloadconsidersthe3ormoreequalspanscondition.Allowableloaddoesnotaddresswebcrippling,fasteners,support

materialorloadtesting.Panelweightisnotconsidered.

3. DeectionconsiderationislimitedbyamaximumdeectionratioofL/180ofspan.

4. Allowableloadsdonotincludea1/3stressincreaseforwind.

5. Diaphragm Capacity-246plfaverageUltimateShearStrengthusingtheabovefasteningpatternon2xsupportslocated2'oncenter,

per ASTM E 455.

ALLOWABLE UNIFORM LOADS, psf

For various fastener spacings

1.5’ 2’ 2.5’ 3’ 3.5’ 4’ 1.5’ 2’ 2.5’ 3’ 3.5’ 4’

SECTION PROPERTIES

Bottom in Compression

Width

in

Yield

ksi

36 80

36 80

36 50

29

Ga

26

24

Sxx

in

3

/ft

Ixx

in

4

/ft

Weight

psf

0.63

0.80

1.05

Top in Compression

Sxx

in

3

/ft

Ixx

in

4

/ft

Inward Load Outward Load

0.0097 0.0162 0.0060 0.0140 171 97 62 43 32 24 197 112 72 50 37 25

0.0123 0.0207 0.0080 0.0181 221 125 81 56 41 32 251 143 92 64 47 32

0.0163 0.0268 0.0117 0.0241 245 139 90 62 46 35 271 154 99 69 51 39

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

8

CLASSIC RIB

®

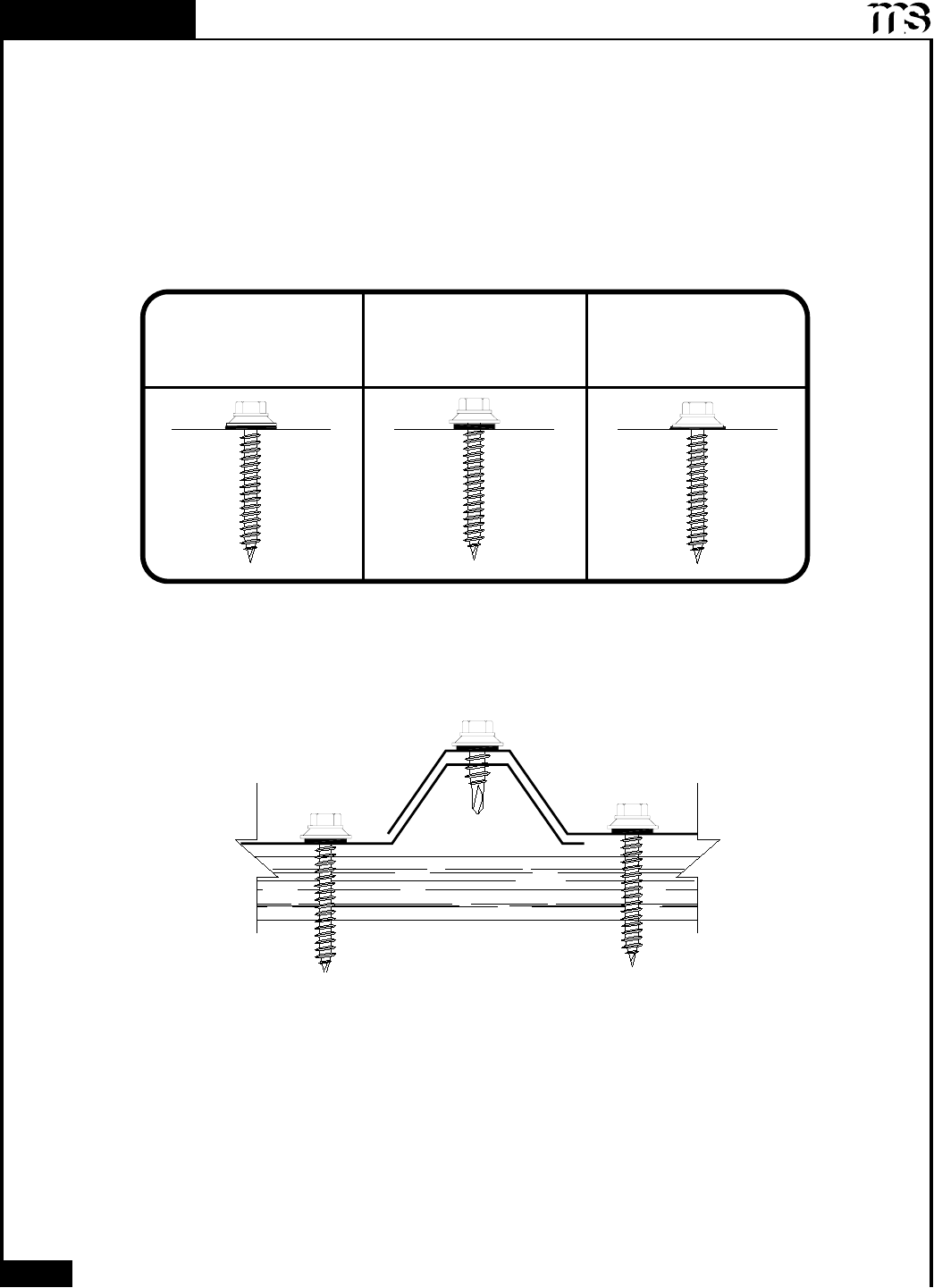

FASTENER INSTALLATION

USING SCREWS:

Forfasteningwithscrews,itisbesttouseapaintedorplatedscrew,TypeAordrillertipwithaatrubberwasher.The

correctscrewgunisalsoimportanttotheproperinstallationofself-drillingorself-tappingscrews.Atoolwiththeappropriate

speedandtorquesetting(asrecommendedbythefastenermanufacturer)willhelppreventfastenerthreadstrip-outand

possibledamagetothepaneloritscoating.Typically40screwsshouldbeusedpersquarefor2'widepanelsand80screws

shouldbeusedpersquarefor3' wide panels.

SCREW ATTACHMENT

CORRECT

Sealingmaterialslightly

visibleatedgeofwasher.

Assemblyiswatertight.

TOO LOOSE

Sealingmaterialisnot

visible;notenough

compression to seal.

TOO TIGHT

Washerisdeformed;

sealingmaterialpressed

beyondfasteneredge.

SEATING THE WASHER-Applysufcienttorquetoseatthewasher-donotoverdrivethefastener.

TO PREVENT WOBBLING-Makesurefastenerheadiscompletelyengagedinthesocket.Iftheheaddoesnotgoall

thewayinthesocket-tapthemagnetdeeperintothesockettoallowfullheadengagement.Metalchipswillbuild

upfromdrillingandshouldberemovedfromtimetotime.

PROTECT DRILL POINT-Pushonlyhardenoughonthescrewguntoengageclutch.Thispreventsexcessfrictionand

burnoutofthedrillpoint.Correctpressurewillallowscrewtodrillandtapwithoutbinding.

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

9

CLASSIC RIB

®

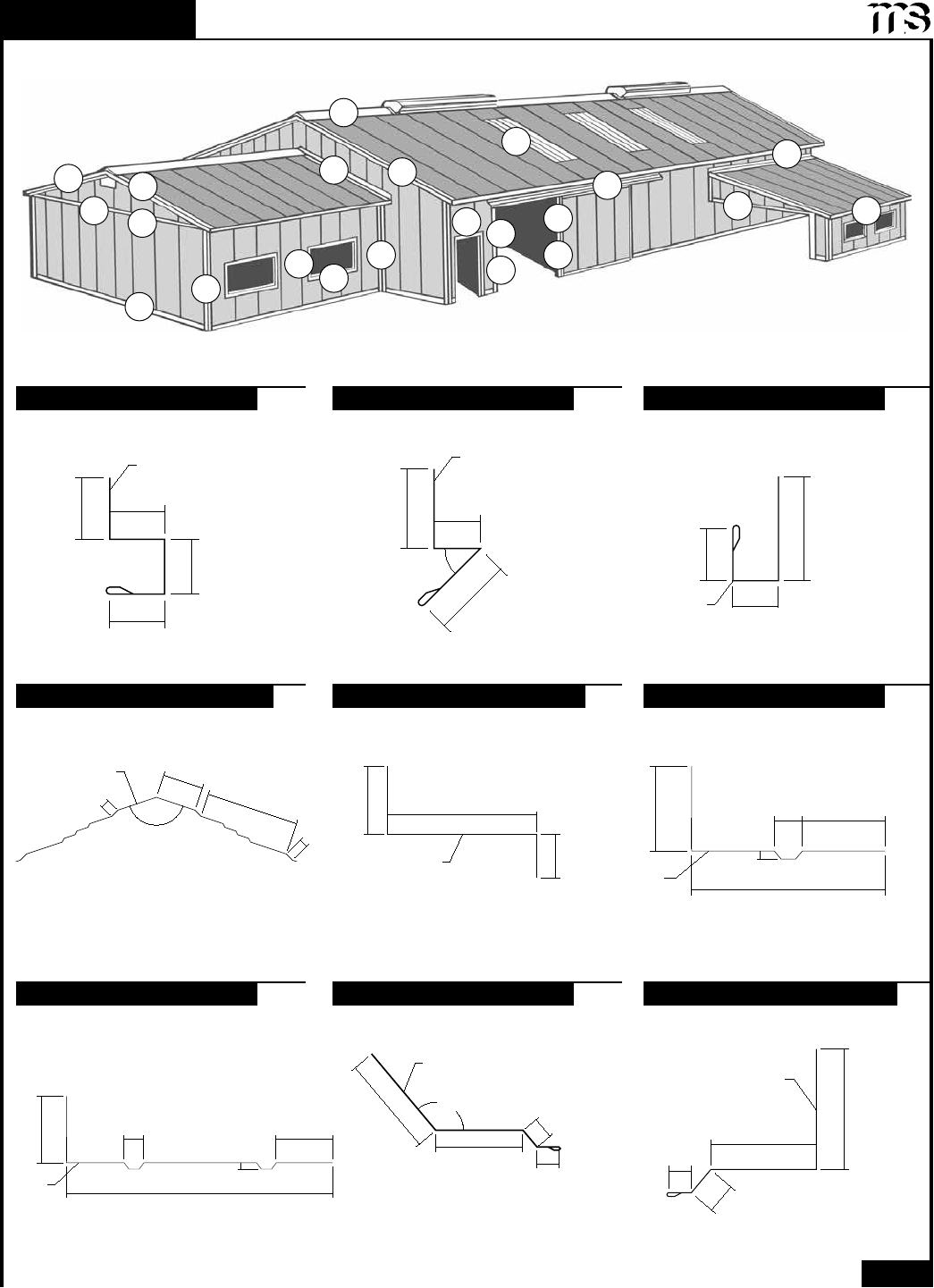

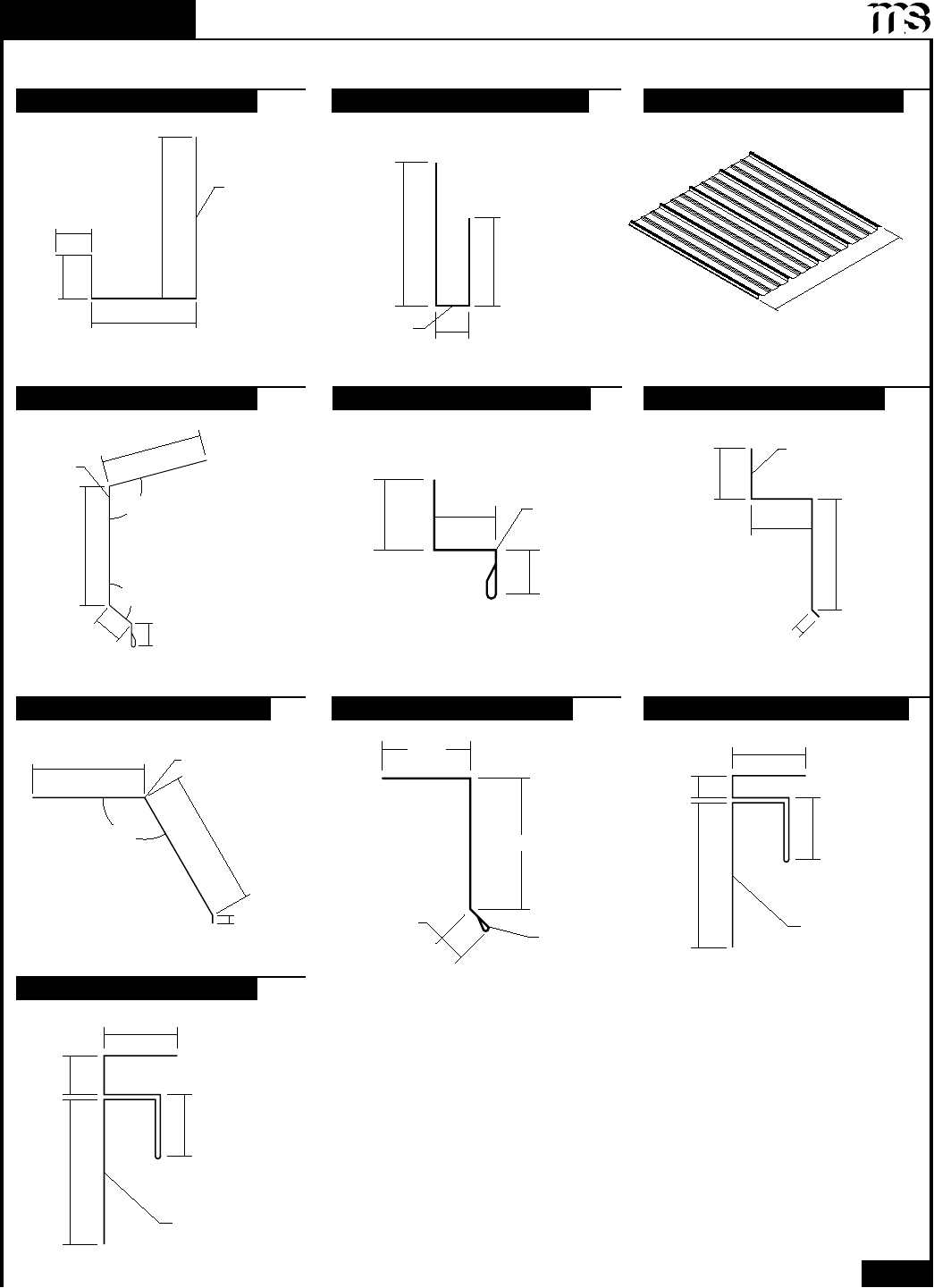

1 - BASE MOLDING

POST FRAME FLASHING PROFILES

1 - ANGLE BASE 2 - J-CHANNEL

3 - 14" UNIVERSAL RIDGE

4 - SOFFIT

4 - 12" SOFFIT

4 - 24" SOFFIT

5 - UNIVERSAL ENDWALL

1"

C

1"

1"

1"

1

1

/

2

"

C

7

/

8

"

1

1

/

2

"

45°

C

7

/

8

"

2"

1"

C

3

/

8

"

1

3

/

4

"

143°

4"

3

/

8

"

C

3

1

/

2

"

12"

5

1

/

2

"

C

5

1

/

8

"

12"

5

1

/

2

"

1

3

/

4

"

C

5

1

/

8

"

24"

5

1

/

2

"

1

3

/

4

"

C

3

1

/

2

"

5"

3

/

4

"

1"

143°

12

23

4

22

1

13

3

18

2

8

16

7

9

17

15

6

10

20

5

14

21

1

/

2

"

1

/

2

"

6 - UNIVERSAL SIDEWALL

C

3

1

/

2

"

4"

1"

7

/

8

"

11

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

10

CLASSIC RIB

®

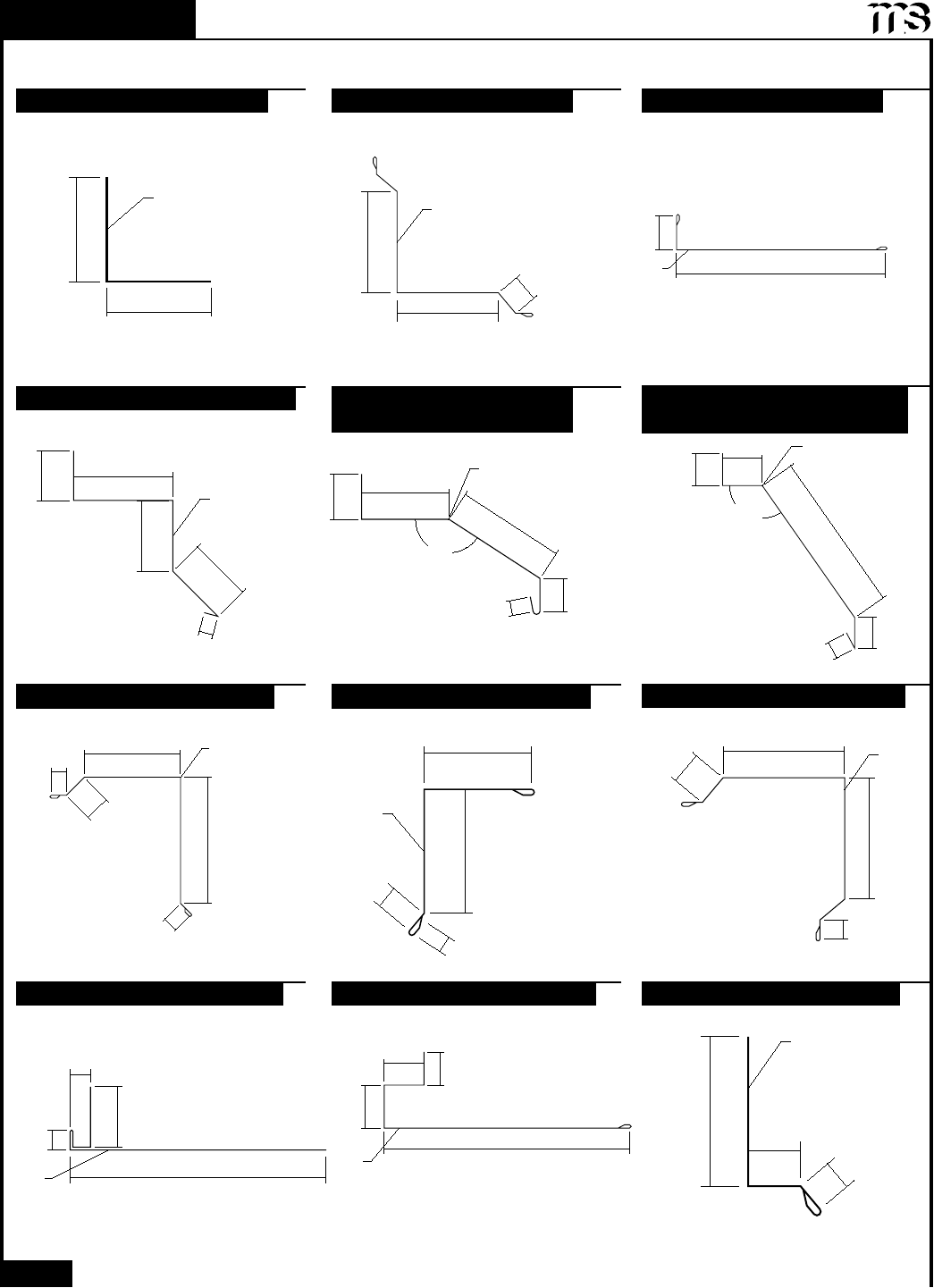

POST FRAME FLASHING PROFILES

7 - MINI ANGLE 8 - INSIDE CORNER

9 - POST TRIM

10 - TOP MOUNT TRACK

COVER

10 - NATIONAL TRACK COVER

10 - CANNONBALL TRACK

COVER

12 - RAKE TRIM 13 - OUTSIDE CORNER

14 - OVERHEAD DOOR TRIM

C

1

1

/

2

"

1

1

/

2

"

C

1"

4"

4"

C

9

1

/

4

"

1

1

/

2

"

C

2

1

/

4

"

2

1

/

2

"

3

1

/

2

"

1

3

/

4

"

1

/

2

"

1

7

/

8

"

4

1

/

2

"

3

5

/

8

"

C

1

3

/

8

"

5

/

8

"

147°

C

1

3

/

8

"

3

/

4

"

1

5

/

16

"

6

7

/

8

"

1

11

/

16

"

147°

2

3

/

4

"

C

2

3

/

8

"

3

/

8

"

1

/

2

"

5

/

8

"

C

4"

4"

1"

C

7

/

8

"

1

7

/

8

"

3

/

4

"

7

7

/

8

"

C

1

7

/

8

"

9

1

/

4

" or 7

1

/

4

"

1

5

/

8

"

1

1

/

2

"

11 - GABLE TRIM

7

/

8

"

2

1

/

2

"

1

/

2

"

C

15 - DOOR JAMB 16 - DRIP CAP

4"

5

/

8

"

5

1

/

4

"

C

1

1

/

16

"

5

/

8

"

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

11

CLASSIC RIB

®

POST FRAME FLASHING PROFILES

18 - FRAMING CLOSURE

21 - EAVE MOLDING 22 - DOUBLE ANGLE

17 - DOOR POST TRIM 20 - TRANSLUCENT PANEL

23 - WIDE Z-METAL

24 - UNIVERSAL GAMBREL

3

1

/

4

"

C

2"

3

/

4

"

See Panel Profile

For Dimensions

LENGTHS: 8'-0",10'-0",12'-0"

1

1

/

8

"

C

7

/

8

"

5

/

8

"

1

1

/

4

"

C

1

1

/

2

"

2

3

/

4

"

1

/

4

"

C

4

1

/

4

"

3

1

/

2

"

1

/

4

"

120°

25 - RAKE / EAVE TRIM 26 - 3/8" F & J-CHANNEL

C

2

3

/

4

"

3

/

8

"

1"

1

1

/

4

"

C

2

1

/

4

"

3

/

4

"

1"

1

1

/

4

"

4

1

/

8

"

C

3

1

/

2

"

3

/

4

"

105°

130°

1

3

/

16

"

1

1

/

4

"

1

1

/

2

"

5

5

/

8

"

3

5

/

8

"

C

26 - 3/4" F & J-CHANNEL

1

5

/

8

"

2

3

/

4

"

1

/

2

"

3

/

8

" Hem

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

12

CLASSIC RIB

®

RESIDENTIAL FLASHING PROFILES

1 - RIDGE / HIP COVER

2 - GABLE TRIM

3 - EAVE TRIM

4 - UNIVERSAL ENDWALL

10"

C

C

1

1

/

2

"

1"

5

/

8

"

C

3

7

/

8

"

3"

5

1

/

2

"

4"

5

/

8

"

5

1

/

4

"

C

1

1

/

16

"

5

/

8

"

C

3

1

/

2

"

4"

7

/

8

"

1"

4 - PITCH BREAK

5 - UNIVERSAL SIDEWALL

6 - VALLEY

C

1"

C

4"

9

1

/

2

"

6"

C

3

1

/

2

"

4"

1"

7

/

8

"

1

1

6

3

2

5

4

1 - 13" STEP RIDGE / HIP

COVER

Specify Angle

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

13

CLASSIC RIB

®

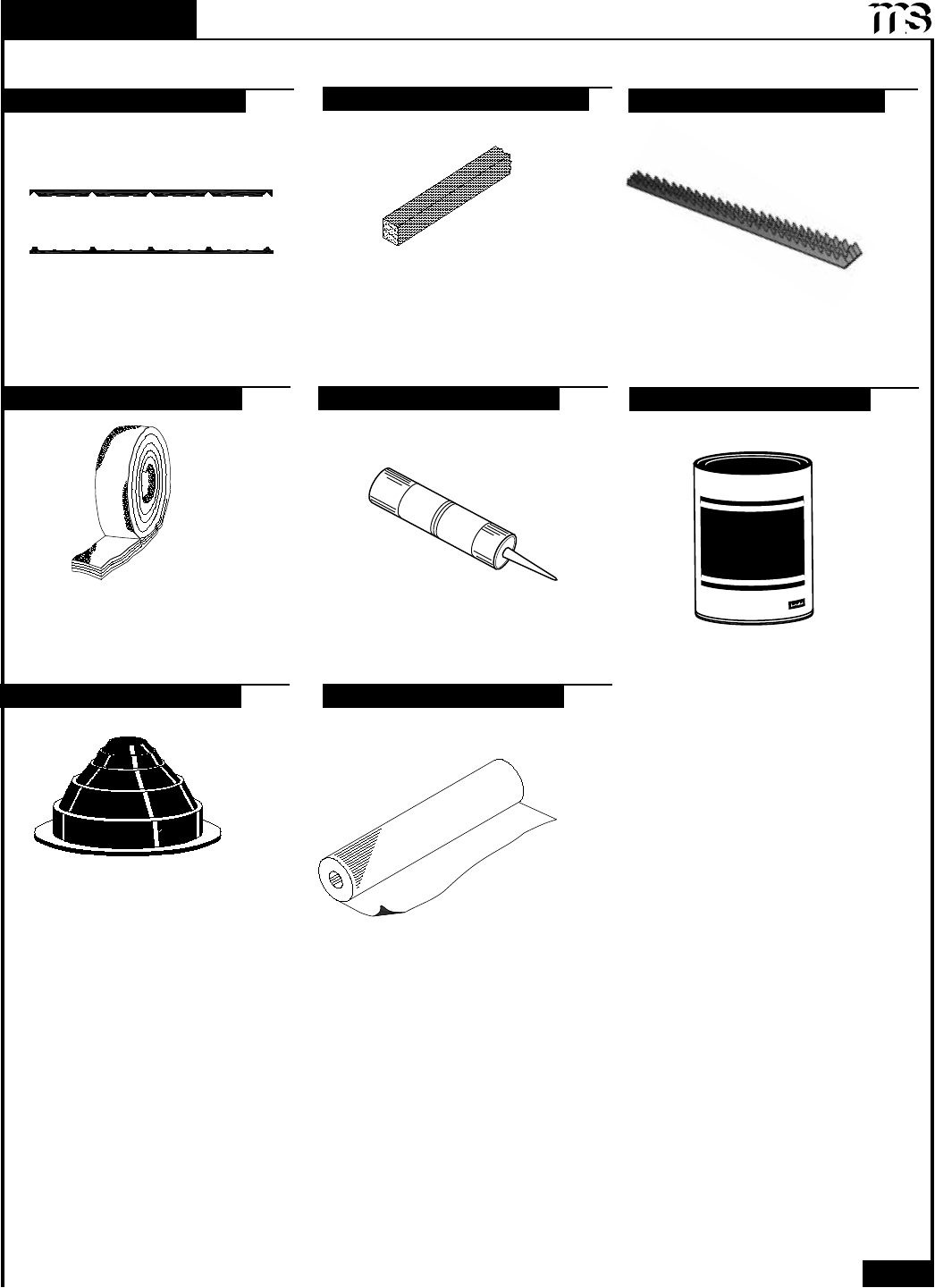

ACCESSORY PROFILES

MINI (

1

/

4

" TO 1

1

/

8

" O.D. PIPE)

#2 (1

3

/

4

" TO 3" O.D. PIPE)

#4 (3" TO 6" O.D. PIPE)

#6 (6" TO 9" O.D. PIPE)

#8 (7" TO 13" O.D. PIPE)

10.3 oz. CARTRIDGE

URETHANE

VERSA VENT

TAPE SEALANT

TUBE SEALANT

RUBBER ROOF JACK

TOUCH-UP PAINT

CLASSIC RIB CLOSURES

UNIVERSAL CLOSURE

3

/

8

" X

3

/

32

" X 50'

SINGLE BEAD

BUTYL - GRAY

1" x 3'-0"

POLYETHYLENE FOAM

1" x 1 1/2" x 50'-0"

1" x 1 1/2" x 10'-0"

MS-HT UNDERLAYMENT

OUTSIDE

INSIDE

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

14

CLASSIC RIB

®

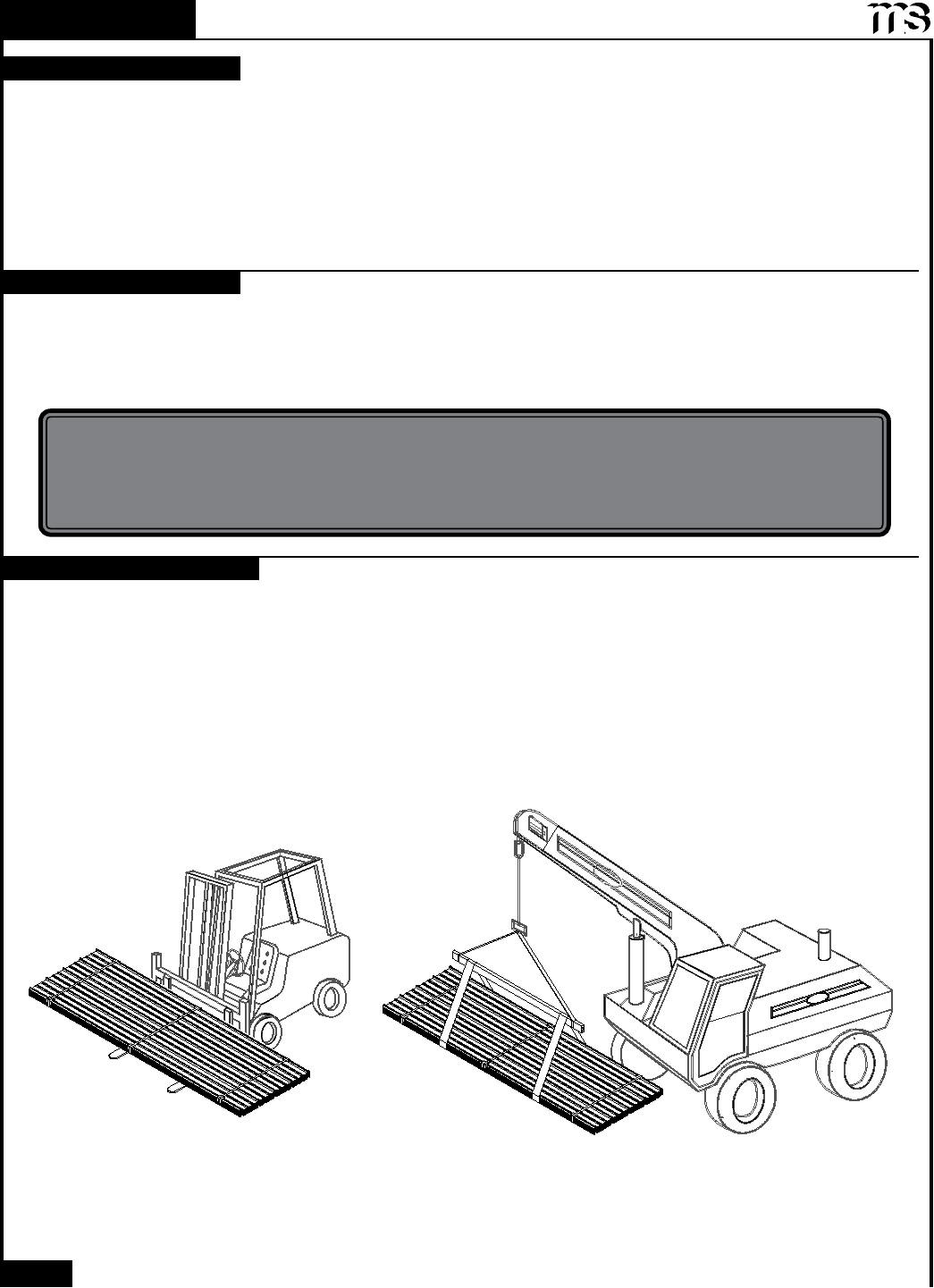

Itistheresponsibilityoftheinstallertounloadmaterialfromthedeliverytruck.Theinstallershallberesponsiblefor

providingsuitableequipmentforunloadingofmaterialfromthedelivery.

Afterreceivingmaterial,checktheconditionofthematerial,andreviewtheshipmentagainsttheshippinglisttoensureall

materialsareaccountedfor.Ifdamagesorshortagesarediscovered,itshouldbenotedontheBillofLadingatthetimeof

delivery.Aclaimshouldbemadeagainstthecarrierassoonaspossible.MetalSalesisnotresponsibleforanydamagesor

shortagesunlesstheyaredocumentedinwritingandpresentedtoMetalSaleswithin48hours.

Eachbundleshouldbehandledcarefullytoavoidbeingdamaged.Careshouldbetakentopreventbendingofthe

panelorabrasiontonish.Wheneverpossible,thebundleshouldremaincrateduntilitislocatedinitsplaceofstor-

age.Ifbundlesmustbeopened,werecommendyoure-cratethembeforelifting.Toavoiddamagepleaseliftthe

bundleatitscenterofgravity.

Forklift -Aforkliftmaybeusedforpanelsupto20'-0"long.Pleasemakesuretheforksareattheirmaximumseparation.

Donottransportopenbundles.Whentransportingbundlesacrossroughterrain,oroveralongerdistance,somemeansof

supportingthepanelloadmustbeused.

Crane -Acraneshouldbeusedwhenliftingpanelswithlengthsgreaterthan20'-0".Pleasebesuretoutilizeaspreaderbarto

ensuretheevendistributionoftheweighttothepickuppoints.Asarulewhenliftingpanels,nomorethan

1

/

3

ofthelengthof

thepanelshouldbeleftunsupported.Neverusewireropebecausethiswilldamagethepanels.

HANDLING MATERIAL

RECEIVING MATERIAL

GENERAL HANDLING

MECHANICAL HANDLING

CAUTION

Improper loading and unloading of bundles and crates may result in bodily harm and/or

material damage. Metal Sales is not responsible for bodily injuries and/or material

damages resulting from improper loading and unloading.

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

15

CLASSIC RIB

®

Whenhandlingpaintedsteel,careshouldbetakentopreventscratchingofmaterial.Cleanglovesshouldbewornatalltimes

topreventareactionwithsaltsfoundonbareskin.Installersshouldwearrubbersoleshoestokeepfromscuffingmaterial

whilewalkingontheroof.

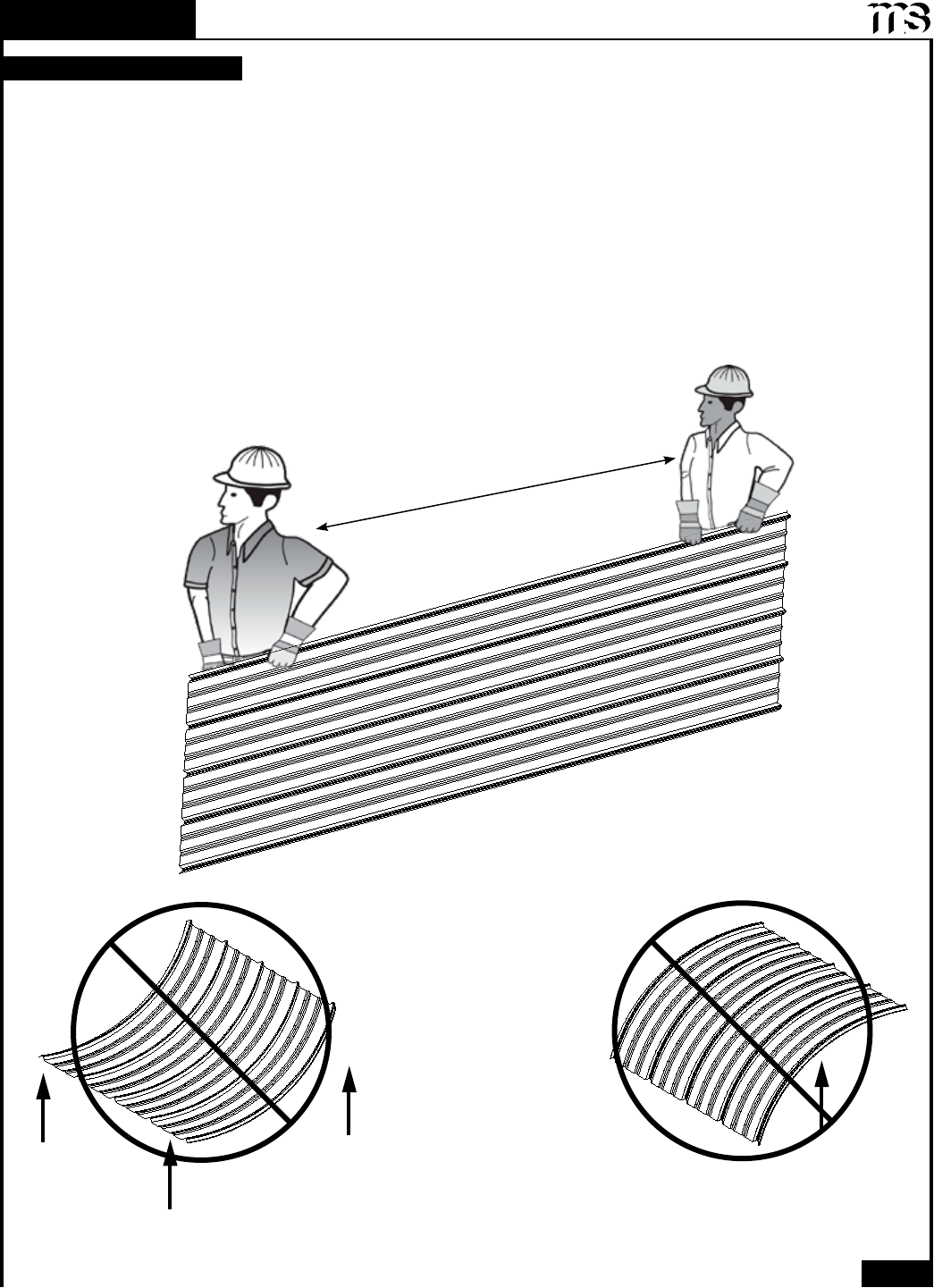

Handlingofindividualpanelsshouldbedonecarefullyandproperlytoavoidbendingordamaging.Panelsshouldbecarried

bygraspingtheedgeofthepanelsothatthepanelisverticaltotheground.Thepanelshouldnotbecarriedhorizontaltothe

groundasthiscouldcausethepaneltobuckleorbendinthecenter.

Normally,individualpanelscanbehandledbypeopleplacedevery6'-0"to8'-0"alongthelengthofthepanel.

INCORRECT

MANUAL HANDLING

CORRECT

6' - 8' MAX

HANDLING MATERIAL (cont.)

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

16

CLASSIC RIB

®

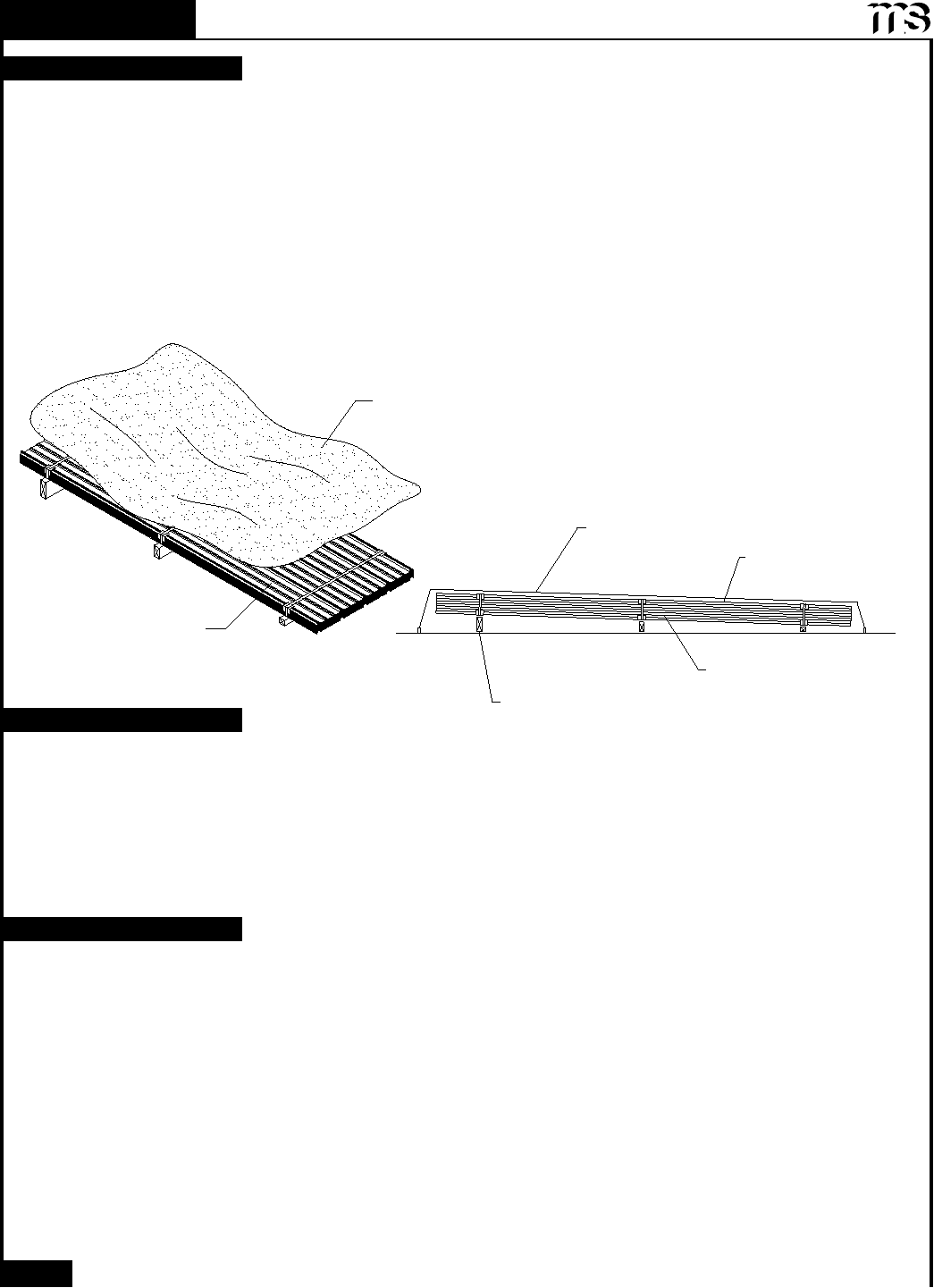

PANELS

TARP

Pleaseinspectpanelsformoistureaccumulation.Ifmoisturehasformed,thepanelsshouldbeunbundled,wipeddry,and

allowedtodrycompletely.Oncedry,carefullyre-stackthepanelsandlooselyrecoverallowingforampleaircirculation.

Bundledsheetsshouldbestoredhighenoughoffofthegroundtoallowforaircirculationandpreventcontactwith

accumulatingwater.Elevateoneendofthebundletoallowanymoisturetorunoffthepanels.MetalSalesrecommends

coveringthebundlewithatarp.Donotusetightttingplastic-typetarpsaspanelbundlecovers.Whiletheymayprovide

protectionfromheavydownpours,theycanalsoretardnecessaryventilationandtrapheatandmoisturethatmayaccelerate

metalcorrosion.Ifpanelsaretobestoredinpossiblebadweather,wesuggesttheybestoredinside.Extendedstorageof

panels in a bundle is not recommended. Under no circumstances should the panels be stored near or come in contact

with salt water, corrosive chemicals, ash or fumes generated or released inside the building or nearby plants,

foundries, plating works, kilns, fertilizer and wet or green lumber.

STORAGE

GENERAL

ELEVATE END OF BUNDLE

Careofmetalpanelsandashingsmustbeexercisedthroughouterection.Foottrafccancausedistortionofpaneland

damagetonish.Trafcovertheinstalledsystemmustbekepttoanabsoluteminimum.Installersshouldwearrubber

soleshoestokeepfromscufngmaterialwhilewalkingontheroof.

Whenwalkingontheroofpanelsisunavoidable,walkonlyintheatsofthepanel.Walkingontheribscancause

damagetothepanels.

FOOT TRAFFIC

PANEL COVER

SHEET

PANEL COVER

SHEET

TARP

Standardrequiredtoolsforeldinstallationinclude:

• Screw Guns

•MagneticBits

• Metal Nibbler or Shear

• Tin Snips

• Tape Measure

• Hammer

•ChalkLine

•Drillwithbits

•PopRivetGun

REQUIRED TOOLS

•SafetyGoggles

• Gloves

•EarPlugs

•FallProtection

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

17

CLASSIC RIB

®

DESIGN / INSTALLATION CONSIDERATIONS

MetalSales’panelsaredesignedtobeinstalledoveropenframingand/ordirectlyoverawoodsubstrate(minimum5/8”)

with30#feltmoisturebarrier(oranIceandWaterShieldwhenrequiredbyLocalBuildingCodes).

Alwayscheckwithlocalbuildingcodespriortoallinstallationsforanyadditionalrequirementsthatmaybespecictoyour

area.

GalvanizedandGalvalumepanelsshouldnotbeincontactwith,orsubjectto,waterrunofffromcopper,leadoruncoated

steel materials.

Condensatewaterfromairconditioningunitstypicallycontainsdissolvedcopper.Thiscondensateshouldbedischarged

throughaplasticpipeextendedbeyondtheedgeoftheroof.

GENERAL

CONDITION OF SUBSTRUCTURE

Theroofshouldbeinspectedforanytrappedmoistureorstructuraldamagesuchasbowingorsaggingraftersandwarpedor

looseroofpurlinsorsoliddecking.Theseareasshouldberepairedpriortoinstallingnewmetalpanels.

Priortoinstallation,makesuretherearenonailsorfastenersprotrudingfromtheroofframingorwoodsubstratewhichcould

damagethepanelsandimpedetheinstallationprocess.

Wheninstalled,paneldistortionmayoccurifnotappliedoverproperlyalignedanduniformsubstructure.

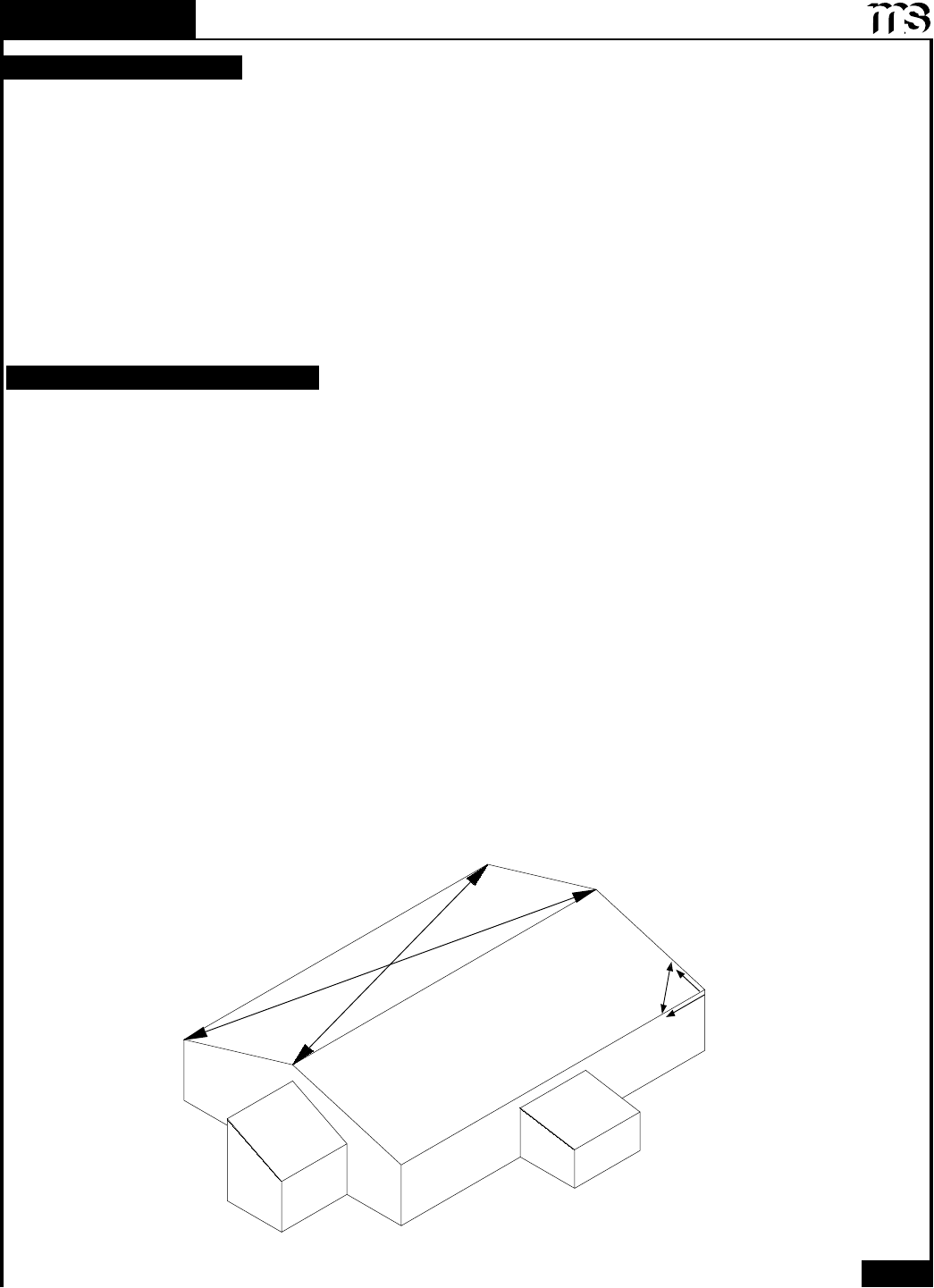

Whetherinstallingoverneworexistingroof,theinstallershouldchecktheroofdeckforsquarenessbeforeinstallingpanels.

Severalmethodscanbeusedtoverifysquarenessofthestructureforproperinstallationofthepanels.

METHOD“A”-Onemethodforcheckingtheroofforsquarenessistomeasurediagonallyacrossoneslopeoftherooffrom

similarpointsattheridgeandeaveandobtainthesamedimension.

METHOD“B”-The3-4-5trianglesystemmayalsobeused.Tousethissystem,measureapointfromthecorneralongthe

edgeoftheroofatamoduleofthree(3).Measureapointfromthesamecorneralonganotheredgeatamoduleoffour(4).

Bymeasuringdiagonallybetweenthetwopointsestablished,thedimensionshouldbeexactlyamoduleofve(5)tohavea

squarecorner.Multipleusesofthissystemmayberequiredtodeterminebuildingsquareness.Iftheendwallcannotbemade

square,theroofsystemcannotbeinstalledasshownintheseinstructions.

METHOD A

METHOD B

10

10

4

3

5

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

18

CLASSIC RIB

®

Tinsnipsora"nibbler"typeelectrictoolarerecommendedforeldcuttingmetalpanels.Cuttingthesteelgeneratesslivers

ormetalchips.Thesesliversandmetalchipsmustbeimmediatelyremovedfromthepanelsbecausetheywilldamagethe

nishandshortenthelifeoftheproduct.

Onemethodofpreventingthisproblemistoipthepanelsoverwhencutting.Thisallowsthesliversandmetalchipstobe

brushedfromthebacksideandavoidsdamagingthepaintonthetopsideofthepanels.

Whencuttingmetalpanelsandashings,gogglesmustbewornforeyeprotection.

CAUTION

All product surfaces should be free of debris at all times. Installed surfaces should be

wiped clean at the end of each work period. Never cut panels over metal surfaces.

Metal shavings will rust on the surface, voiding the warranty.

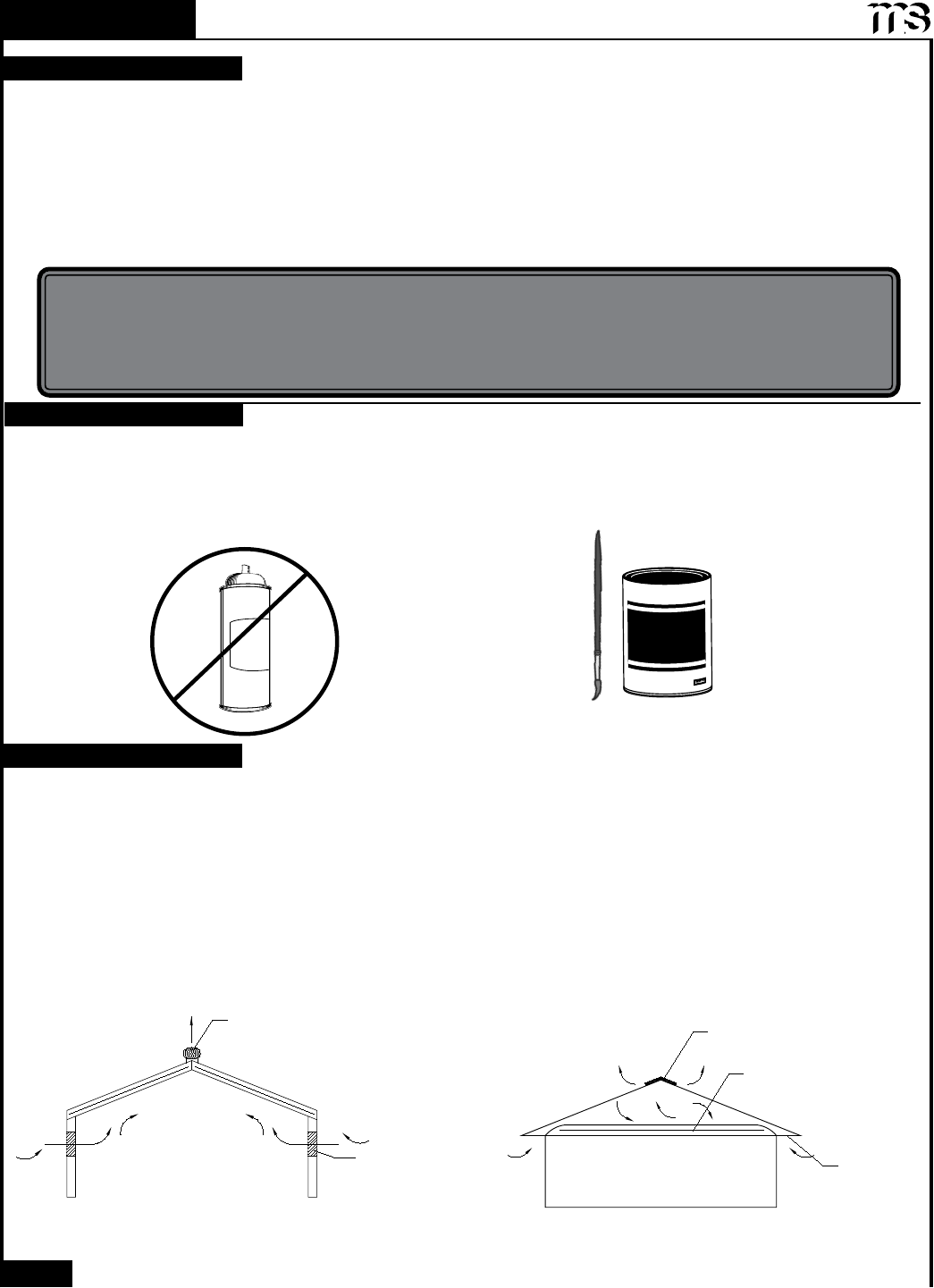

Allpaintedpanelsandashingshaveafactoryappliedbakedonnish.Handlingandinstallingpanelsmayresultinsome

smallscratchesornickstothepaintnish.Touch-uppaintisavailableinmatchingcolorsfromMetalSales.Itisrecom-

mendedthatasmallbrushbeusedtoapplytouch-uppainttothoseareasthatareinneedofrepair.Touch-uppaintdoesnot

havethesuperiorchalkandfaderesistanceofthefactoryappliedpaintnishandwillnormallydiscoloratanaccelerated

rate.Aerosolpaintshouldnotbeusedbecauseoftheoverspraythatmayoccur.

FIELD CUTTING AND TOUCH-UP

TOUCH-UP PAINT

FIELD CUTTING

TOUCH-UP PAINT

SPRAY PAINT

Properdesignandinstallationofvaporbarriersandventilationsystemsareimportanttopreventcondensationandtheresult-

ingproblemsofmoisturedamageandlossofinsulationefciency.

Condensationoccurswhenmoistureladenaircomesincontactwithasurfacetemperatureequaltoorbelowthedewpointof

theair.Thisphenomenoncreatesproblemsthatarenotuniquewithmetalbuildings;theseproblemsarecommontoalltypes

ofconstruction.

Theundersideofthemetalroofonatypicalmetalbuilding(noattic)shouldbeprotectedfromcondensationbyinsulating

withafacedinsulation.Thisshouldreducethepotentialofcondensationformingontheundersideofthepanels.

Onbuildingsthathaveanatticspaceorarebeingretrottedwithametalroongsystem,ventsshouldbeplacedatboththe

eaveandpeakoftheroofinordertopreventabuildupofmoisture(humidity)intheatticspace.

VENTILATION

BUILDING

WITHOUT ATTIC

BUILDING

WITH ATTIC

VENT

WALL VENTS

OR OPENINGS

VENT

ATTIC

INSULATION

VENT AT

EAVE

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

19

CLASSIC RIB

®

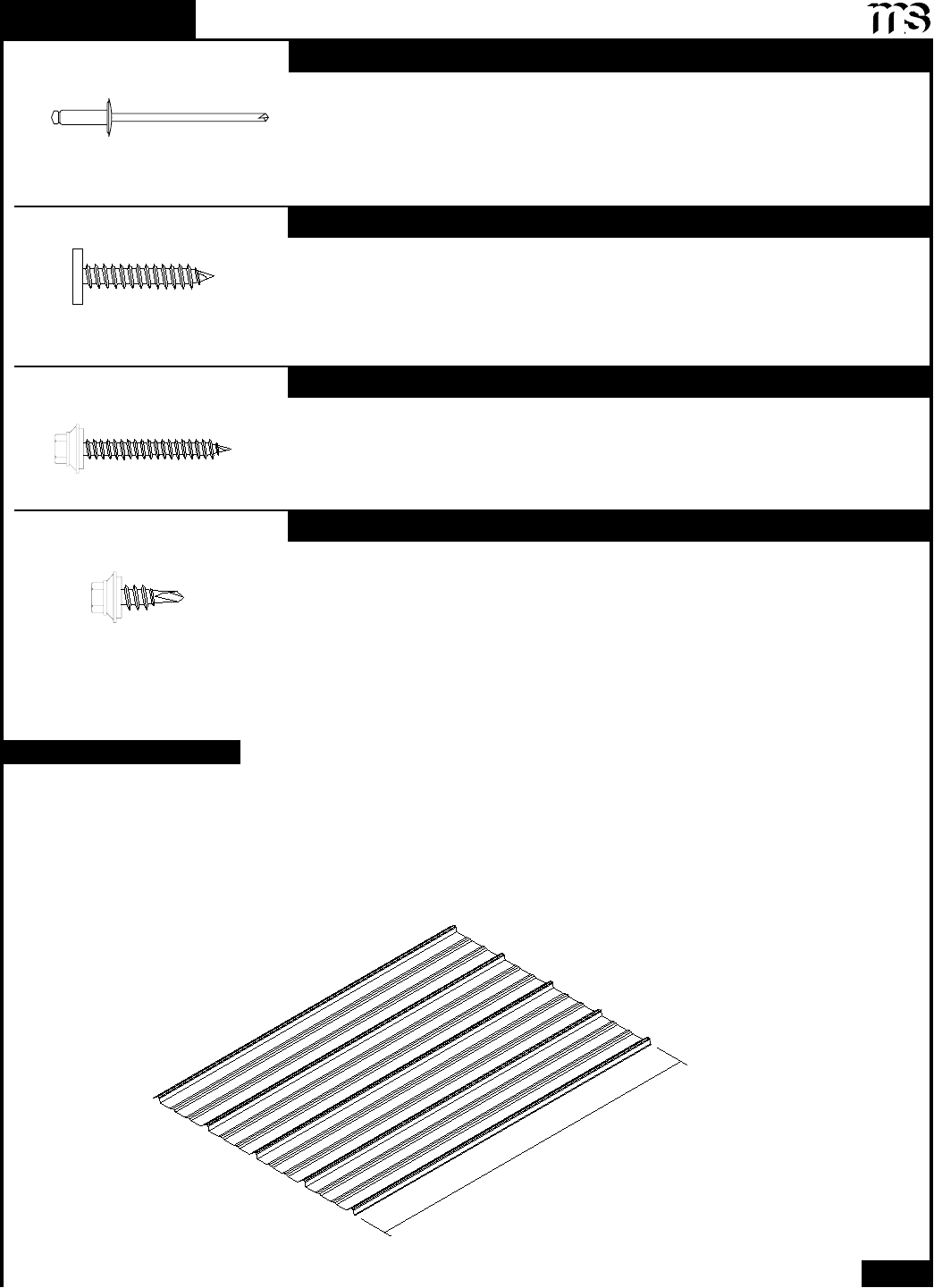

PANCAKE HEAD WOODSCREW

SIZE TYPE FINISH APPLICATION

#10-12 x 1" A Plated Panel or Flashing to

wood substructure

FASTENER SELECTION GUIDE

POP RIVET

SIZE TYPE FINISH APPLICATION

1

/

8

" x

3

/

8

" A Unpainted Flashing to Panel,

Flashing to Flashing

1

/

8

" x

3

/

8

" A

Painted Flashing to Panel,

Flashing to Flashing

#10-14 x 1" A Painted Panel or Flashing

#10-14 x 1

1

/

2

" A Painted to wood substructure

#10-14 x 2" A Painted

WOODSCREW

SIZE TYPE FINISH APPLICATION

1

/

4

"- 14 x

7

/

8

" Stitch Painted Flashing to Panel,

Flashing to Flashing,

Panel Sidelap

STITCH SCREW

SIZE TYPE FINISH APPLICATION

5'-0" MINIMUM

Length -Minimumfactorycutlengthis5'-0"onpanels.Panelsover45'-0"requireadditionalconsiderationinpackaging,

shippinganderection.PleaseconsultMetalSalesforrecommendations.

Therearetwocriticalmeasurementsinvolvingmetalpanels:thelengthofpaneloverhangrequiredattheeave,andthepeak

end.Ineachcaseacertainmeasurementisrequired.Checkeachmeasurementtoensurepanelplacementgivesyouthedis-

tancerequiredattheeave,andpeakcondition.Inmostcasesanyvariancecanbetakenoutattheeaveorpeakends.

PANEL

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

20

CLASSIC RIB

®

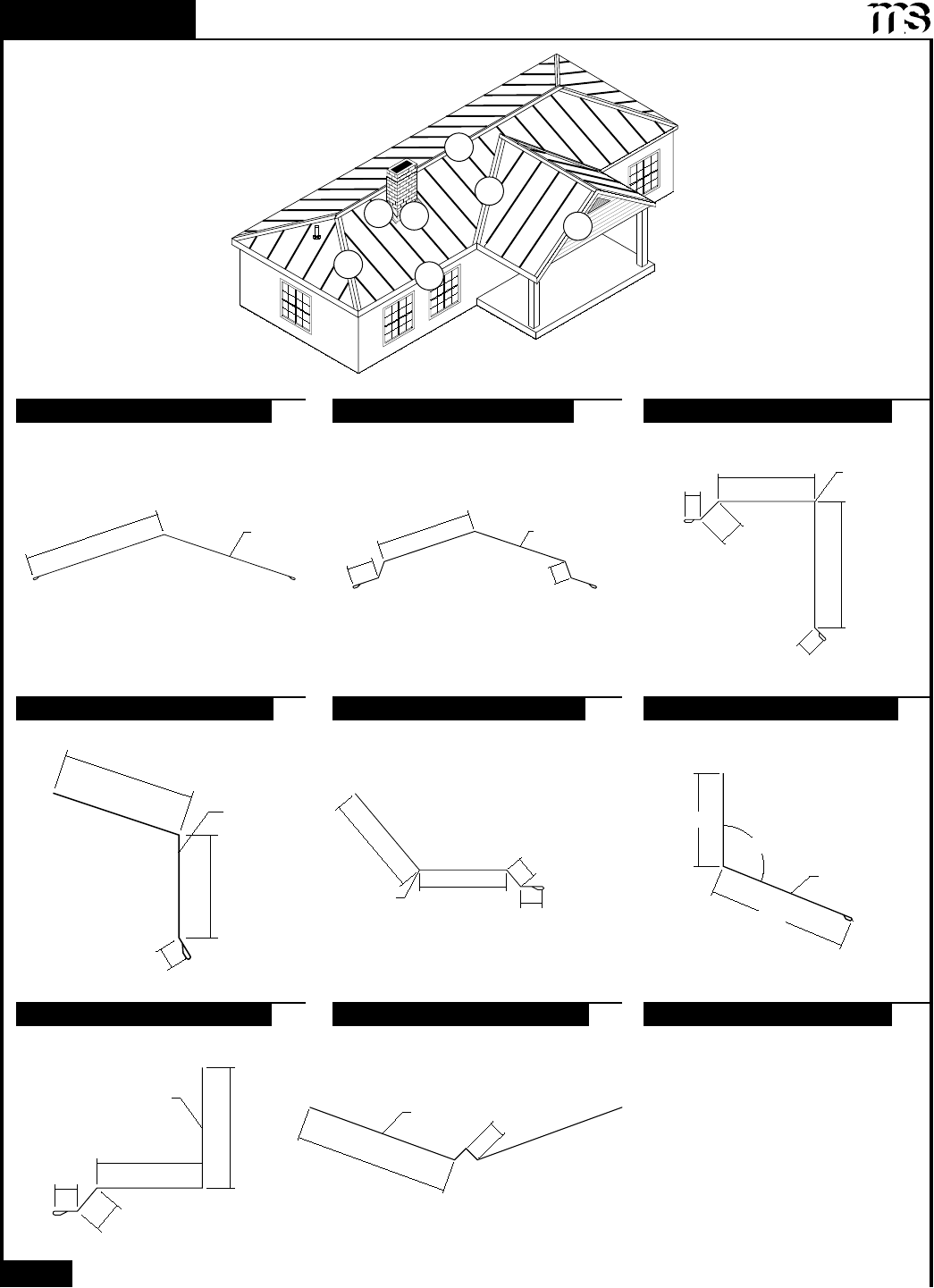

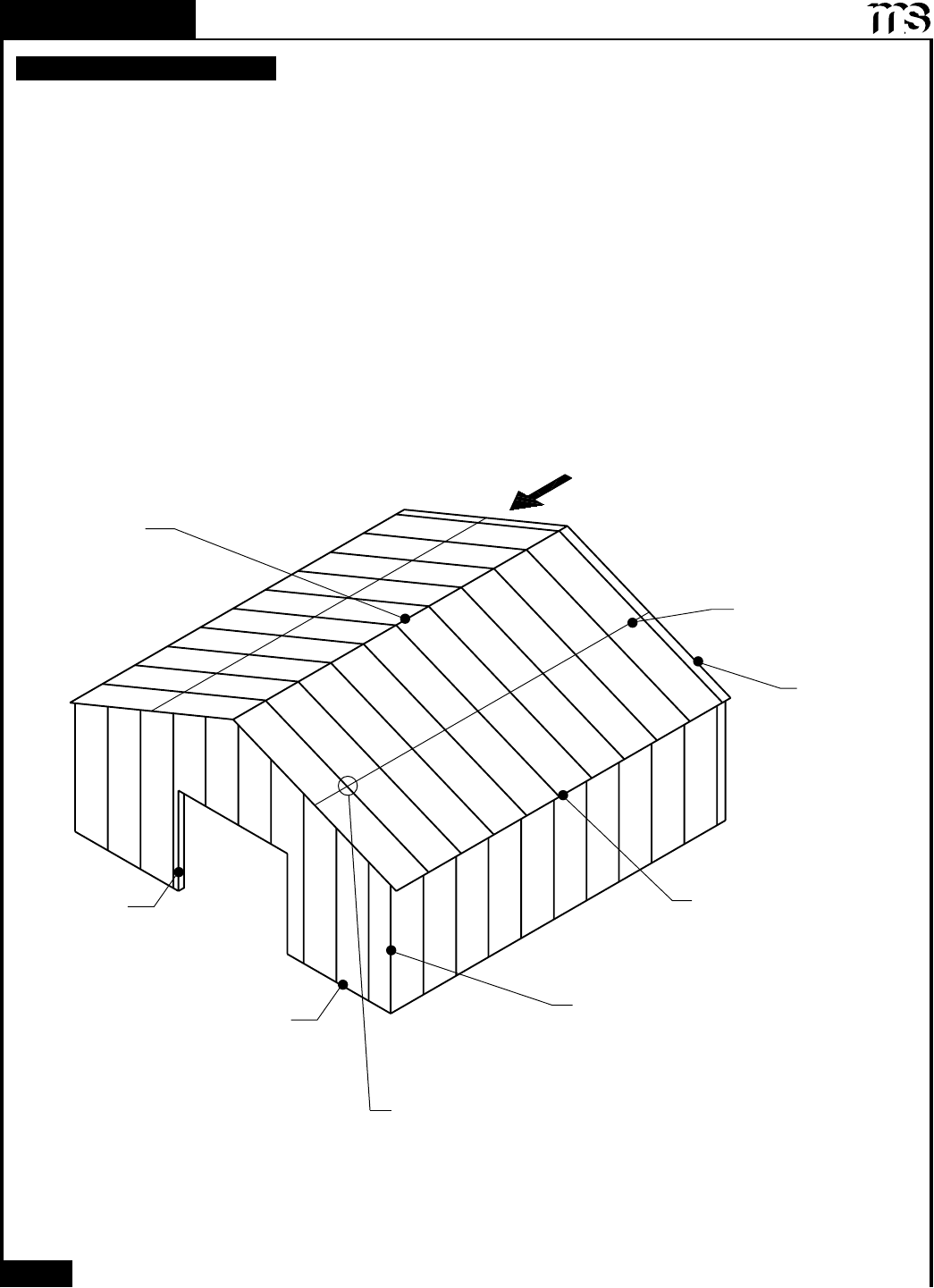

} Asshownbelowwiththenumberdesignations,installpanelagainsttheprevailingwind.InstallingWallPanelsfirstthen

RoofPanels

} Tominimizecorrosion,sidingpanelsshouldnotbeinstalledallthewaytotheground.

} Sidingpanelsshouldlapoverthefoundationsorsplashboardsatleastthreeinches.

} Makesurepanelsaresquareandplumb,toassurestraightandproperalignmentoftheentirerowofpanels.

} Forareaswithhighwindconsiderations,closerfastenerspacingmayberequired.

} Itisnecessarytoattachatemporaryguidetothefoundationtouseasanalignmentguidewheninstallingsidingpanels.

} Anti-Siphongroovesideofpanelmustbeoverlappedwiththenonsiphongroovesideoftheadjacentpanel(ifapplicable)

} When endlapping panels: at the side laps, both of the ridge panels must overlap both eave panels.

} At Endlaps apply Tape Sealant across the full width of the upper end of the eave panels.

INSTALLATION OVERVIEW

INSTALLATION OVERVIEW

Prevailing Winds

ANGLE BASE DETAIL

(SEE PAGE 25)

CORNER DETAIL

(SEE PAGE 23)

EAVE DETAIL

(SEE PAGE 25)

GABLE DETAIL

(SEE PAGE 24)

RIDGE DETAIL

(SEE PAGE 23)

1

PANEL ENDLAP

(SEE PAGE 22)

3

5

2

4

J-CHANNEL

(SEE PAGE 27)

1

3

2

NOTE: Panel 2 will overlap Panel 1 by the order of installation. Panel 2

must also overlap Panel 3 after it is installed. During installation of Panel

3 lift up the lower edge of Panel 2 at tuck Panel 3 under it before installing

Panel 4. This installation will be the same throughout the length of the

endlapped panels.

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

21

CLASSIC RIB

®

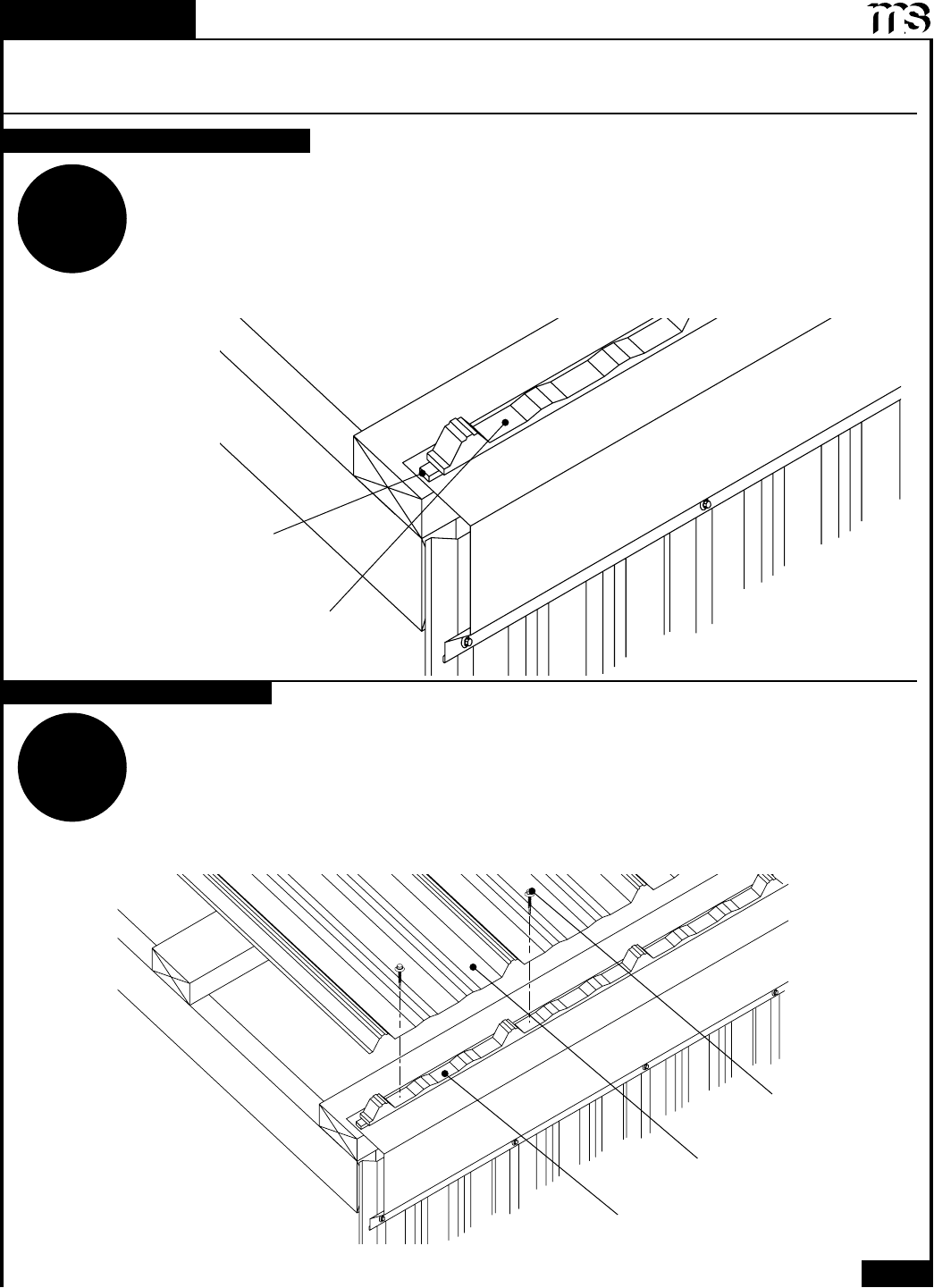

1. Apply a row of Tape Sealant across the top leg of the Eave Molding along the width of the

building.

2. Align and place Inside Closures over the Tape Sealant. It is critical that Inside Closures are

square to building as this will control the alignment of the panels. (See page 17 to check

building square).

3. Apply a row of Tape Sealant across the top of the Inside Closure (Not shown for clarity).

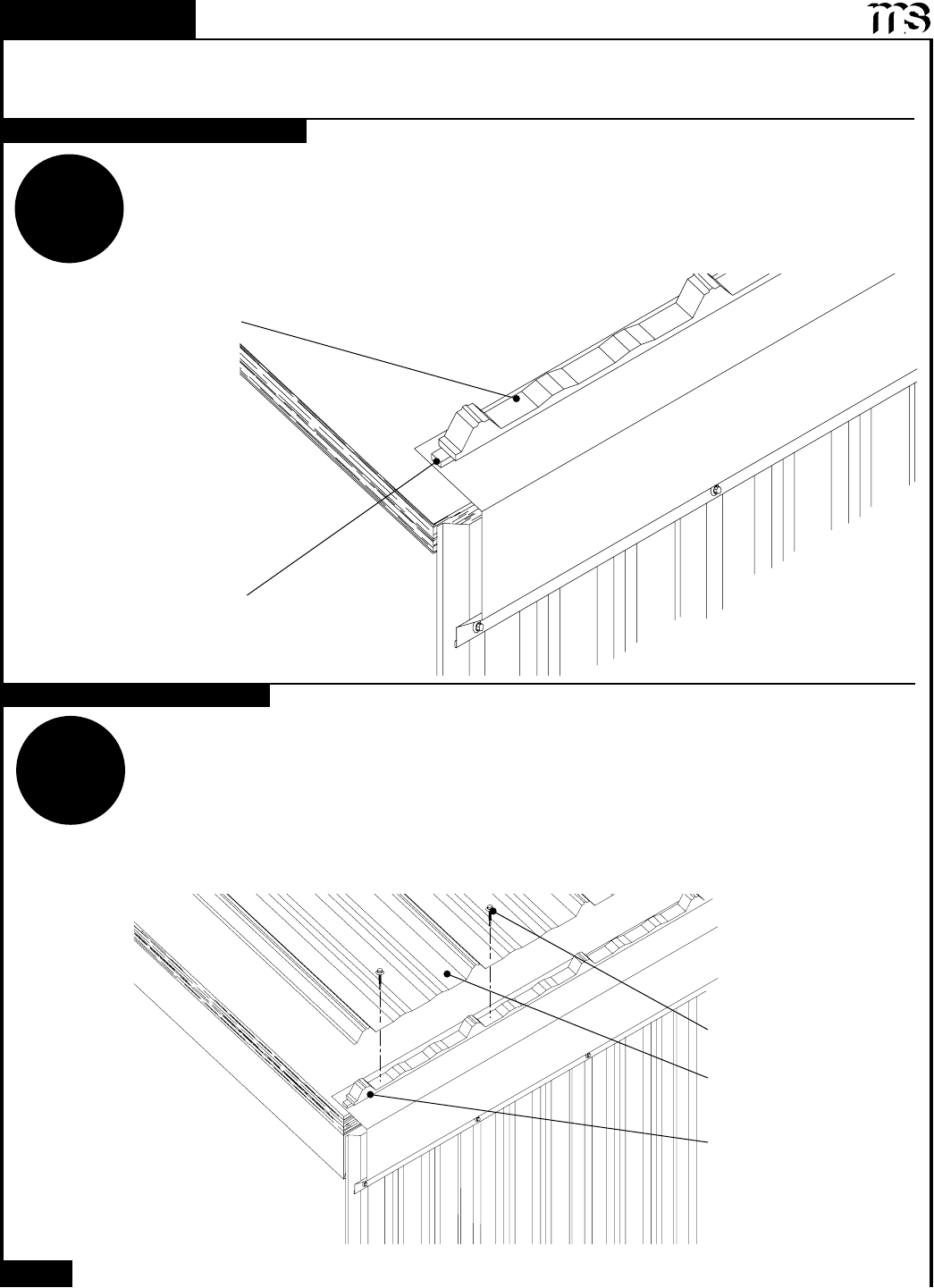

POST FRAME PANEL INSTALLATION

NOTE: -Eave Molding, Gutter and Valley Flashings must rst be installed before panel installation can begin.

-Panels can be installed going from either left to right or right to left / looking from eave to peak.

INSTALLING FIRST PANEL

INSTALLING INSIDE CLOSURES

1. Install the rst panel over the Inside Closure allowing desired overhang. Make sure the panel is

square to the eave and rake.

2. Fasten through panel, closure and sealants into decking with appropriate amount of fasteners to

meet local building code. (See fastening patterns on page 6). Fasteners must penetrate closure and

sealant.

3. After securing panel at eave, repeat the fastening pattern at all panel support locations.

STEP

1

STEP

2

FASTENER

INSIDE CLOSURE

w/ TAPE SEALANT

TAPE SEALANT

INSIDE CLOSURE

ROOF PANEL

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

22

CLASSIC RIB

®

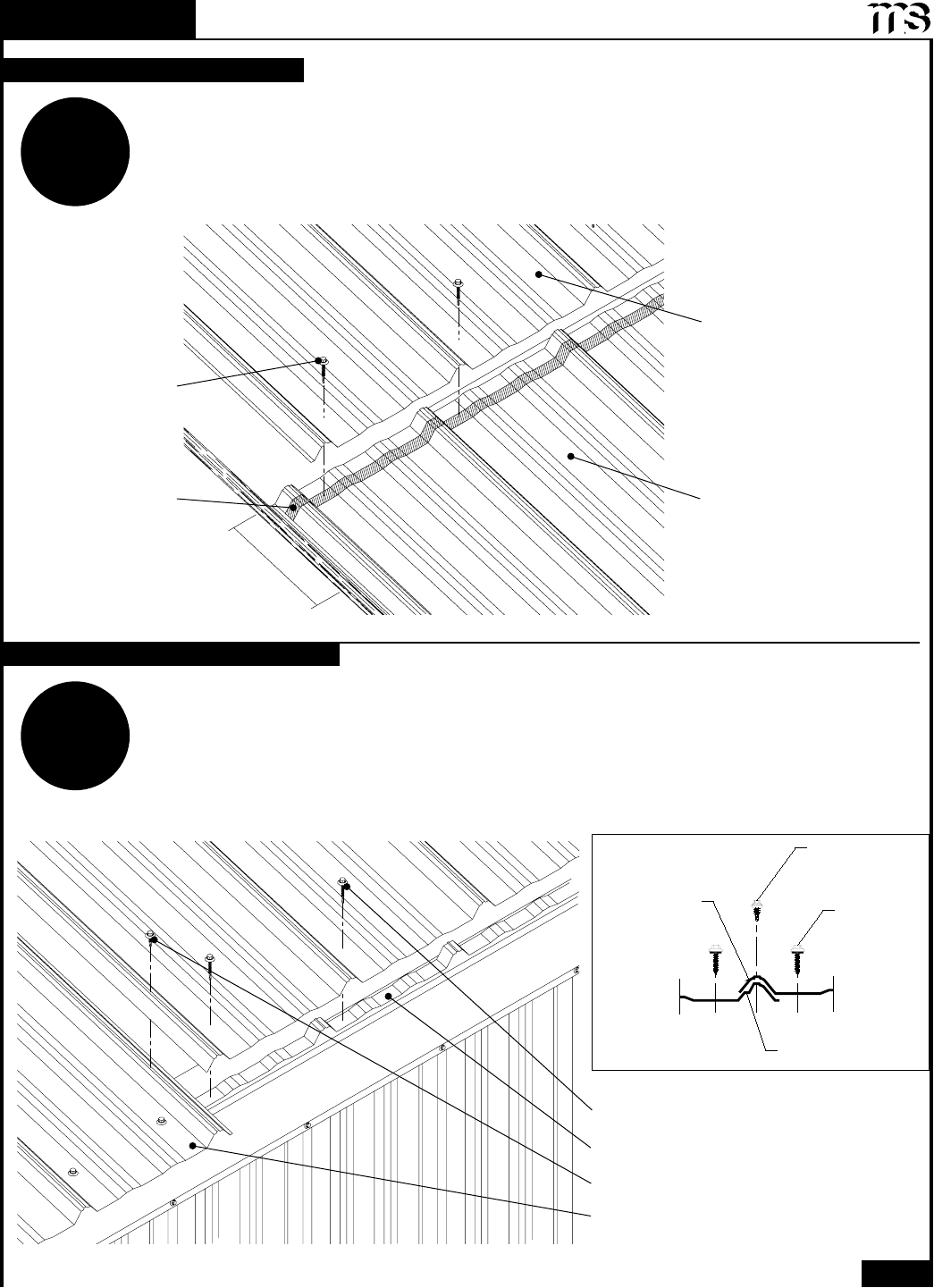

POST FRAME PANEL INSTALLATION

FIRST PANEL INSTALLED

1. ApplyarowofTapeSealantacrossandovertheribsoftheeavepanelabout3"frompanelend.

2. InstalltheridgepanelovertheeavepanelandTapeSealantwitha6"Endlap.Fastenthroughboth

panelsandTapeSealantintosupportwithappropriateamountoffastenerstomeetlocalbuildingcode.

(Seefasteningpatternsonpage6).Fastenersmustpenetratesealant.

3. Aftersecuringpanel,repeatthefasteningpatternatallpanelsupportlocations.

INSTALLING SIDELAP PANEL

1. Placethelappingseamofthesecondpanelontopofpreviouslyinstalledpanelsothatpanelendsare

ushateave(Seebelow).

2. Fastenthroughpanel,closure,andTapeSealantintosupportwithappropriateamountoffastenersto

meetlocalbuildingcode.(Seefasteningpatternsonpage6).Fastenersmustpenetrateclosureand

sealant.

3. Aftersecuringpanel,repeatthefasteningpatternatallpanelsupportlocations.

STEP

3

STEP

4

INSTALLING ENDLAP PANEL

RIDGE PANEL

EAVE PANEL

TAPE SEALANT

FASTENER

INSIDE CLOSURE

EAVE FLASHING

6"

LAP

(IF REQUIRED)

Anti-Siphon Groove

Side Lap Fastener

(for roof only)

Panel Fastener

Classic Rib Panel

STITCH SCREW

Note: when endlapping multiple panels: at the side laps, both the ridge panels must overlap both eave panels.

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

23

CLASSIC RIB

®

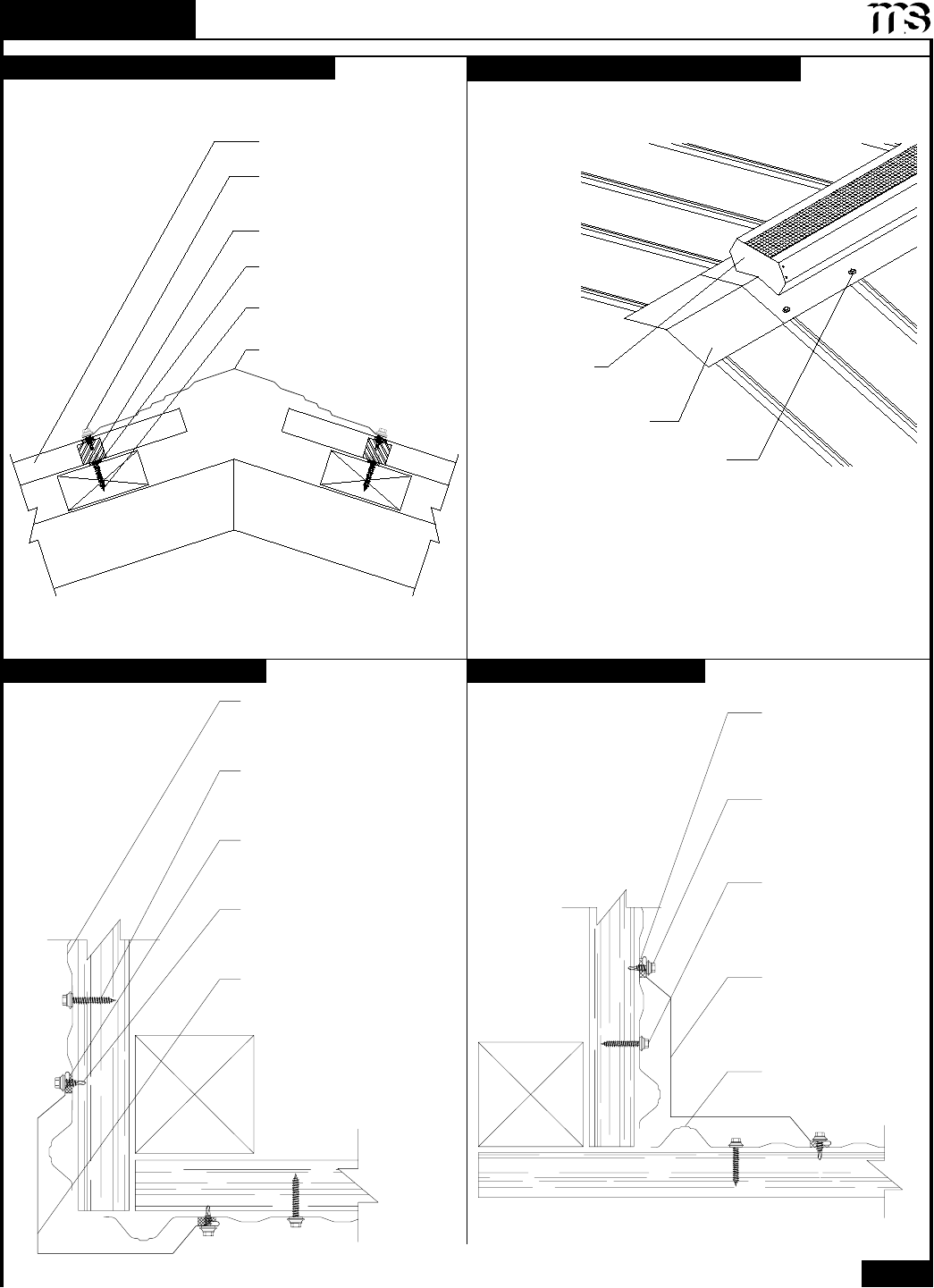

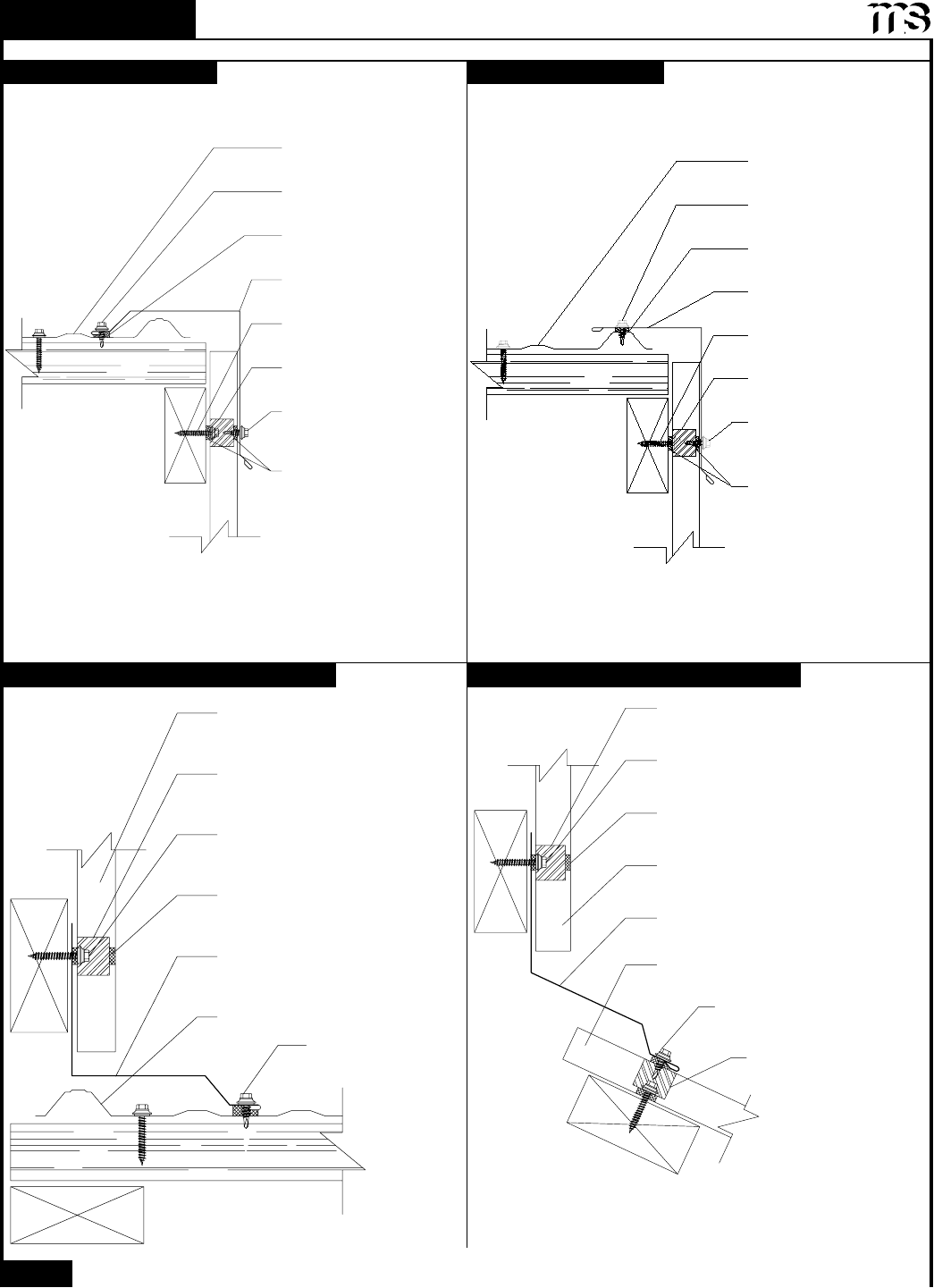

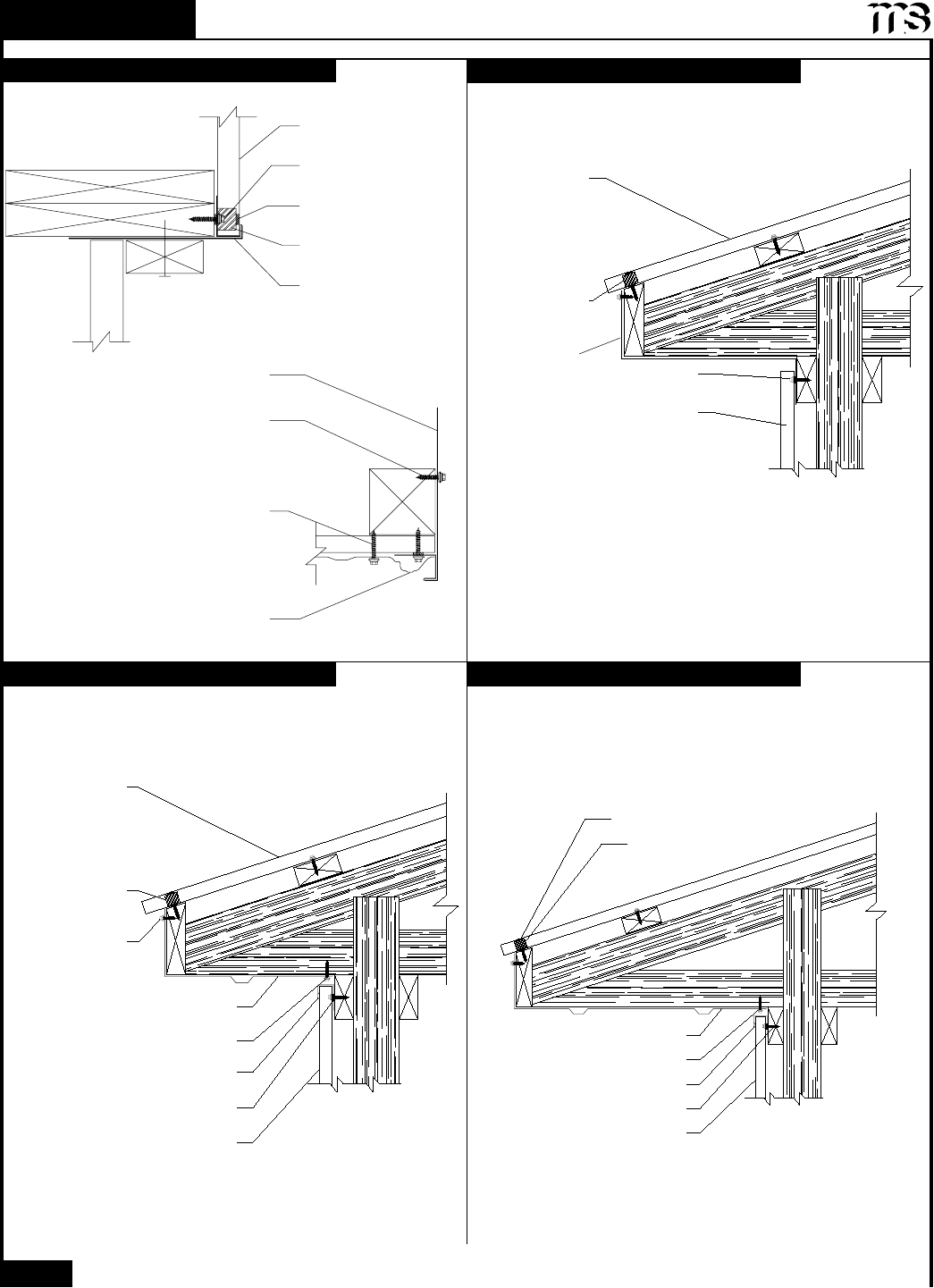

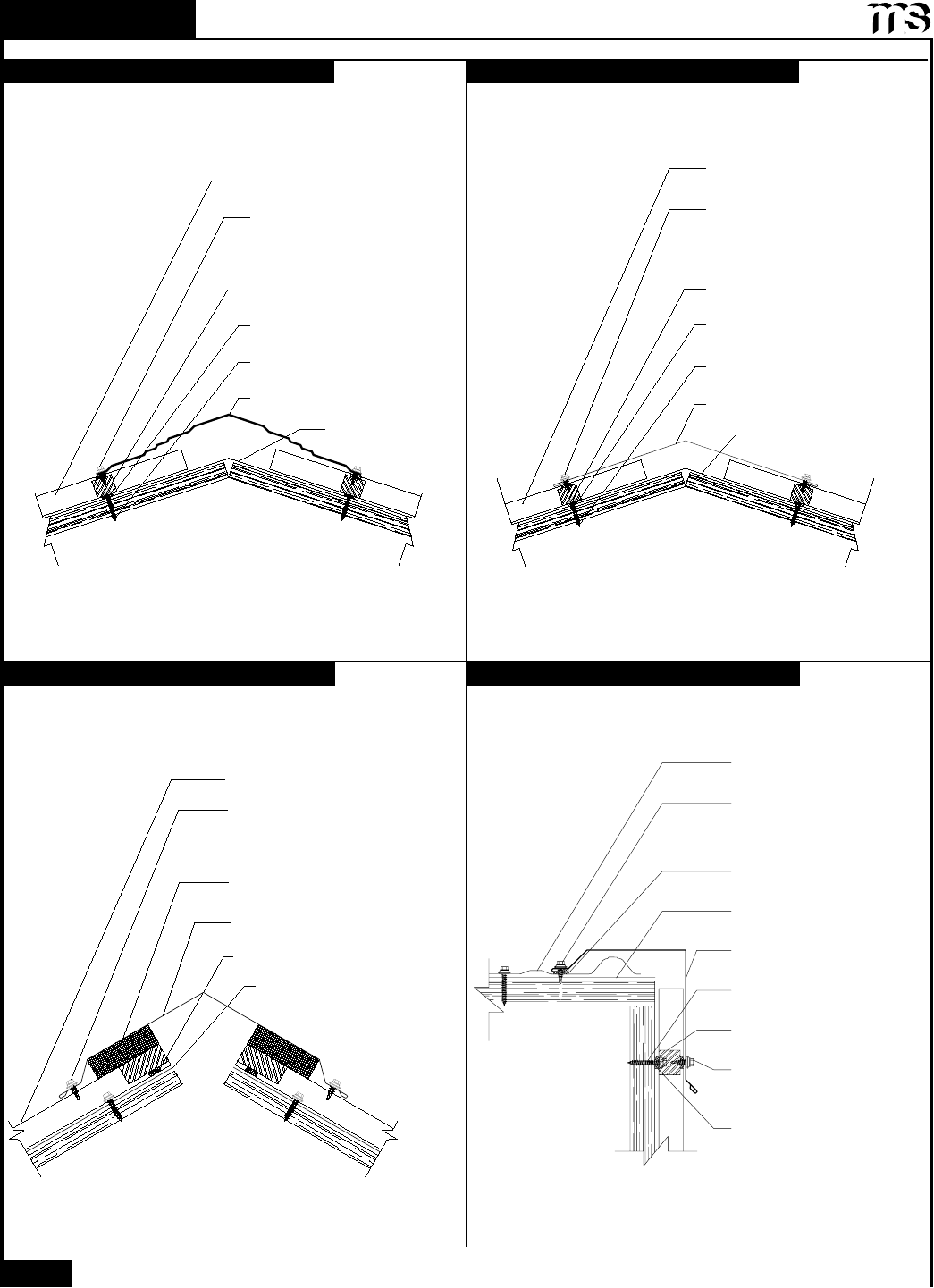

POST FRAME BUILDING DETAILS

14" UNIVERSAL RIDGE DETAIL

INSIDE CORNER DETAIL

OUTSIDE CORNER DETAIL

ROOF PANEL

STITCH SCREW

(EVERY RIB*)

OUTSIDE CLOSURE

FASTENER

TAPE SEALANT

14" OR 20" UNIVERSAL

RIDGE

WALL PANEL

OUTSIDE CORNER

FASTENER

TAPE SEALANT

FASTENER

TAPE SEALANT

STITCH SCREW

(1'-0" O.C.)

WALL PANEL

STITCH SCREW

(1'-0" O.C.)

INSIDE CORNER

LOW PROFILE RIDGE VENT DETAIL

RIDGE VENT

RIDGE / HIP COVER

FASTENER

(EVERY RIB*)

* FASTENER SPACING TO BE 8" - 12" O.C. * FASTENER SPACING TO BE 8" - 12" O.C.

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

24

CLASSIC RIB

®

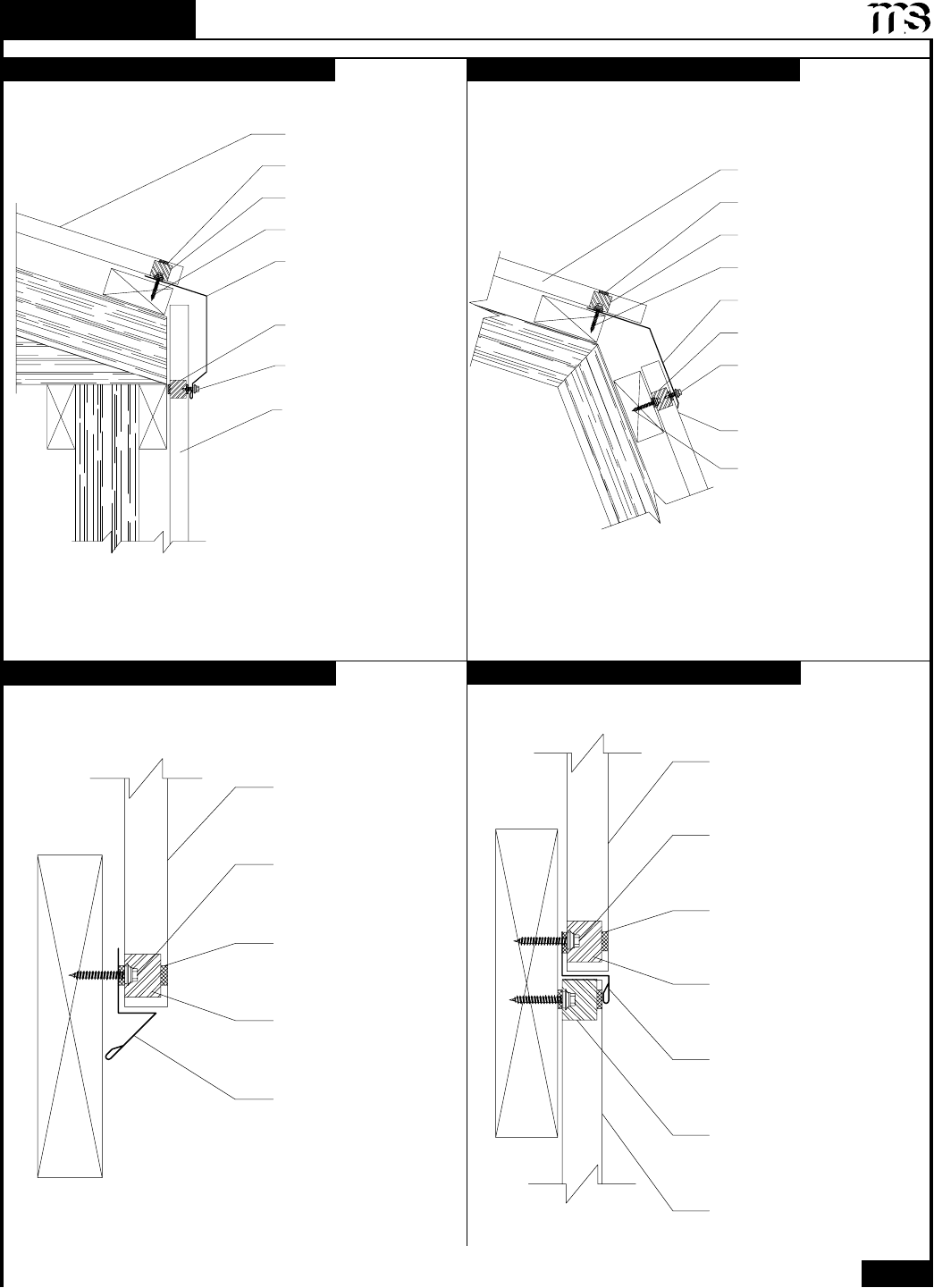

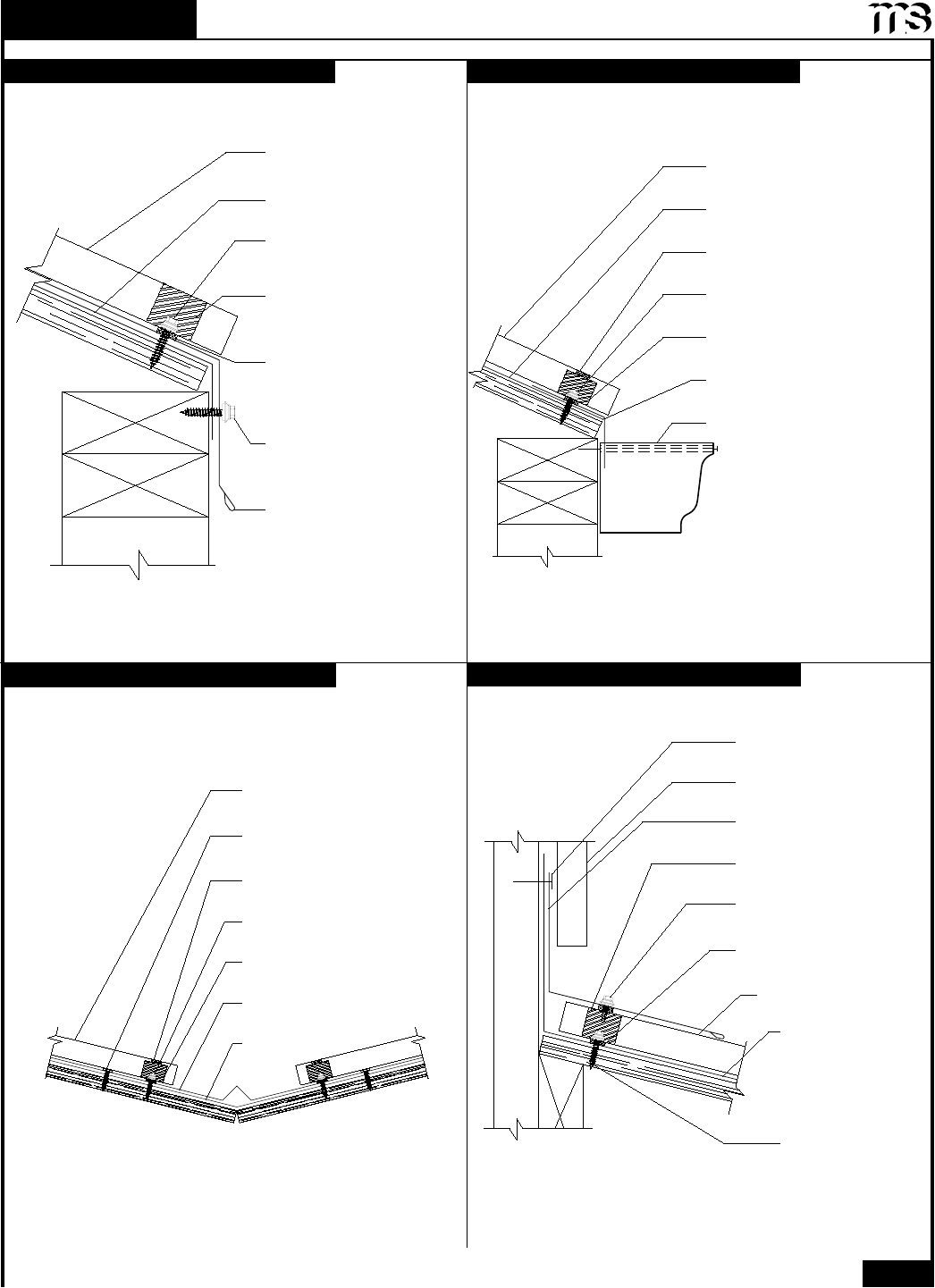

POST FRAME BUILDING DETAILS

GABLE TRIM DETAIL

RAKE TRIM DETAIL

UNIVERSAL SIDEWALL DETAIL

UNIVERSAL ENDWALL DETAIL

ROOF PANEL

STITCH SCREW

(EVERY RIB*)

OUTSIDE CLOSURE

TAPE SEALANT

TAPE SEALANT

FASTENER

GABLE TRIM

ROOF PANEL

STITCH SCREW

(EVERY RIB*)

OUTSIDE CLOSURE

STITCH SCREW

(1'-0" O.C.)

TAPE SEALANT

TAPE SEALANT

FASTENER

RAKE TRIM

WALL PANEL

ROOF PANEL

INSIDE CLOSURE

FASTENER

TAPE SEALANT

UNIVERSAL SIDEWALL

STITCH SCREW

(EVERY RIB*)

INSIDE CLOSURE

FASTENER

TAPE SEALANT

UNIVERSAL ENDWALL

OUTSIDE CLOSURE

WALL PANEL

STITCH SCREW

(1'-0" O.C.)

ROOF PANEL

STITCH SCREW

(1'-0" O.C.)

* FASTENER SPACING TO BE 8" - 12" O.C.

* FASTENER SPACING TO BE 8" - 12" O.C.

* FASTENER SPACING TO BE 8" - 12" O.C.

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

25

CLASSIC RIB

®

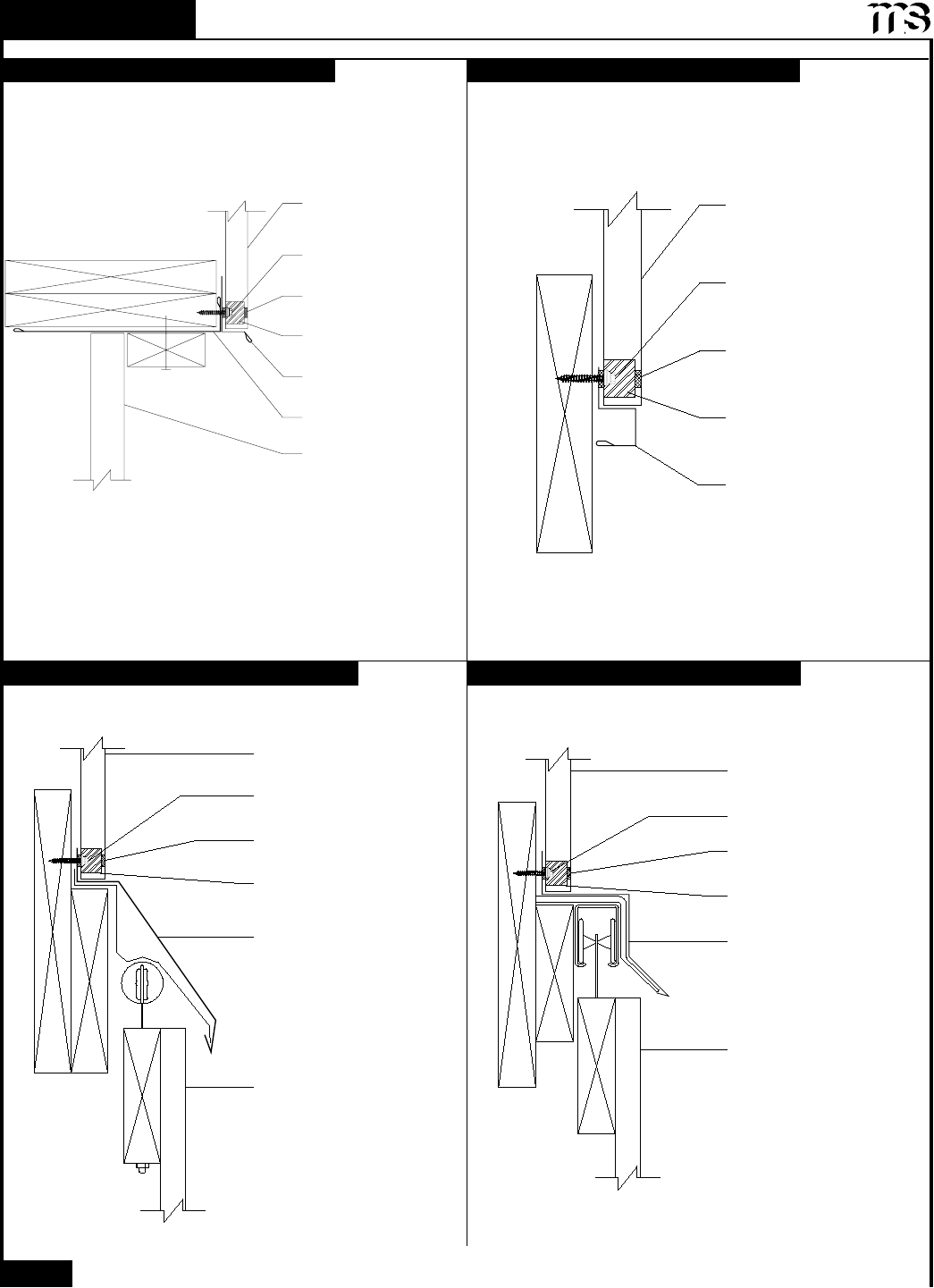

POST FRAME BUILDING DETAILS

EAVE MOLDING DETAIL

UNIVERSAL GAMBREL DETAIL

ANGLE BASE DETAIL

DOUBLE ANGLE DETAIL

ROOF PANEL

INSIDE CLOSURE

FASTENER

TAPE SEALANT

EAVE MOLDING

STITCH SCREW

(EVERY RIB*)

OUTSIDE CLOSURE

WALL PANEL

ROOF PANEL

INSIDE CLOSURE

FASTENER

TAPE SEALANT

UNIVERSAL GAMBREL

STITCH SCREW

(EVERY RIB*)

OUTSIDE CLOSURE

ROOF PANEL

FASTENER

WALL PANEL

INSIDE CLOSURE

TAPE SEALANT

FASTENER

ANGLE BASE

* FASTENER SPACING TO BE 8" - 12" O.C. * FASTENER SPACING TO BE 8" - 12" O.C.

WALL PANEL

INSIDE CLOSURE

TAPE SEALANT

FASTENER

DOUBLE ANGLE

WALL PANEL

INSIDE CLOSURE

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

26

CLASSIC RIB

®

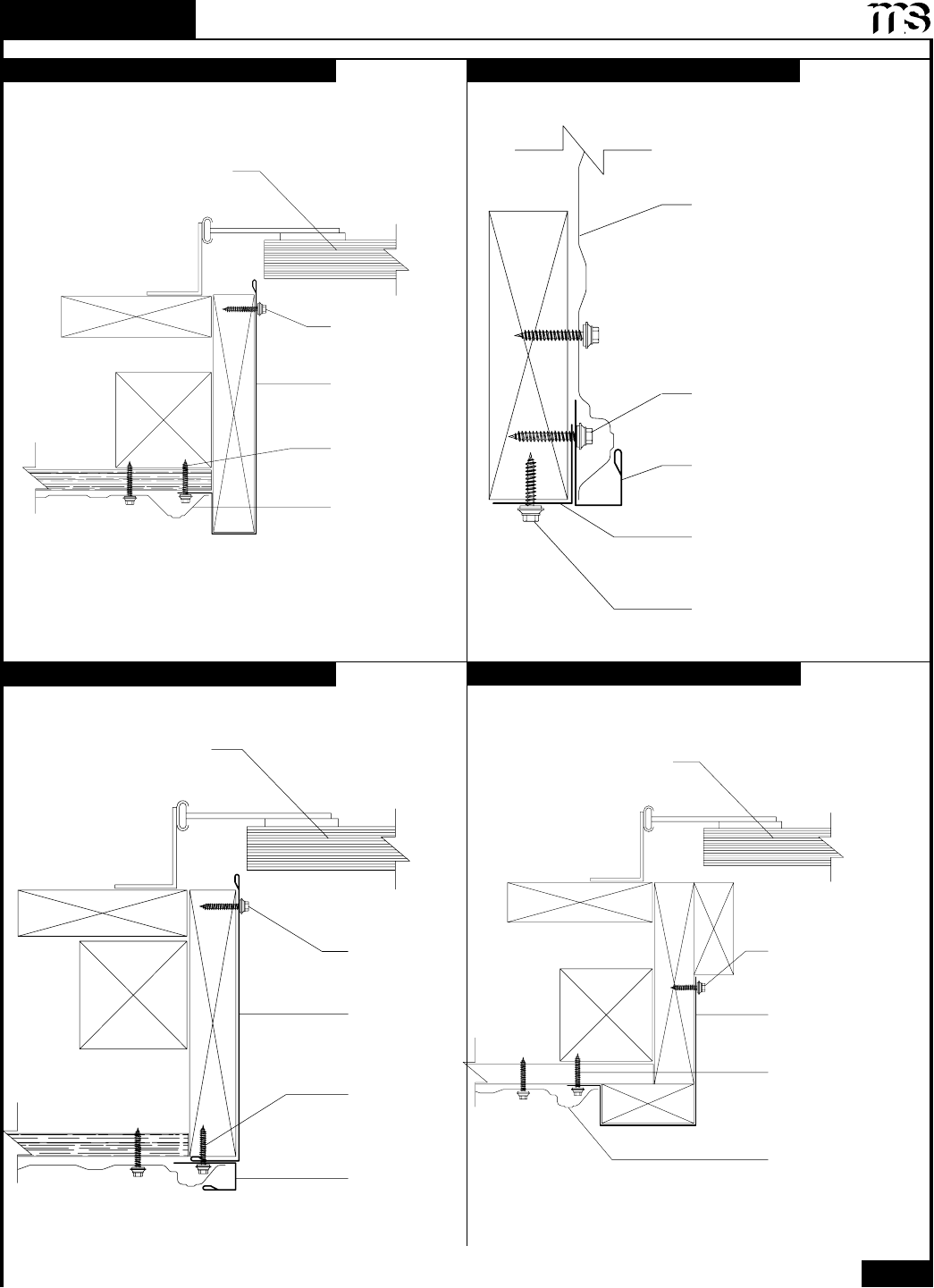

POST FRAME BUILDING DETAILS

DRIP CAP DETAIL

BASE MOLDING DETAIL

CANNONBALL TRACK COVER DETAIL

NATIONAL TRACK COVER DETAIL

WALL PANEL

FASTENER

INSIDE CLOSURE

TAPE SEALANT

DRIP CAP

POST TRIM

WALK THROUGH

DOOR

WALL PANEL

FASTENER

INSIDE CLOSURE

TAPE SEALANT

BASE MOLDING

WALL PANEL

FASTENER

INSIDE CLOSURE

TAPE SEALANT

CANNONBALL TRACK

COVER

SLIDING DOOR

WALL PANEL

FASTENER

INSIDE CLOSURE

TAPE SEALANT

NATIONAL TRACK

COVER

METAL SIDING

ON DOOR

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

27

CLASSIC RIB

®

POST FRAME BUILDING DETAILS

DOOR JAMB DETAIL

MINI-ANGLE / U-FLASHING DETAIL

POST TRIM DETAIL

DOOR POST TRIM DETAIL

FASTENER

DOOR JAMB

FASTENER

WALL PANEL

OVERHEAD DOOR

FASTENER

J-CHANNEL

FASTENER

WALL PANEL

MINI-ANGLE

FASTENER

POST TRIM

FASTENER

OVERHEAD DOOR

J-CHANNEL

FASTENER

DOOR POST TRIM

FASTENER

OVERHEAD DOOR

WALL PANEL

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

28

CLASSIC RIB

®

POST FRAME BUILDING DETAILS

OVERHEAD DOOR TRIM DETAIL

SOFFIT DETAIL

12" SOFFIT DETAIL

24" SOFFIT DETAIL

TAPE SEALANT

FASTENER

WALL PANEL

OVERHEAD DOOR

TRIM

INSIDE CLOSURE

FASTENER

FASTENER

WALL PANEL

OVERHEAD DOOR TRIM

ROOF PANEL

INSIDE

CLOSURE

WALL PANEL

ROOF PANEL

INSIDE

CLOSURE

FASTENER

J-CHANNEL

FASTENER

WALL PANEL

FASTENER

12" SOFFIT

24" SOFFIT

FASTENER

J-CHANNEL

FASTENER

WALL PANEL

TAPE SEALANT

INSIDE CLOSURE

* FASTENER SPACING TO BE 8" - 12" O.C.

FASTENER

SOFFIT

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

29

CLASSIC RIB

®

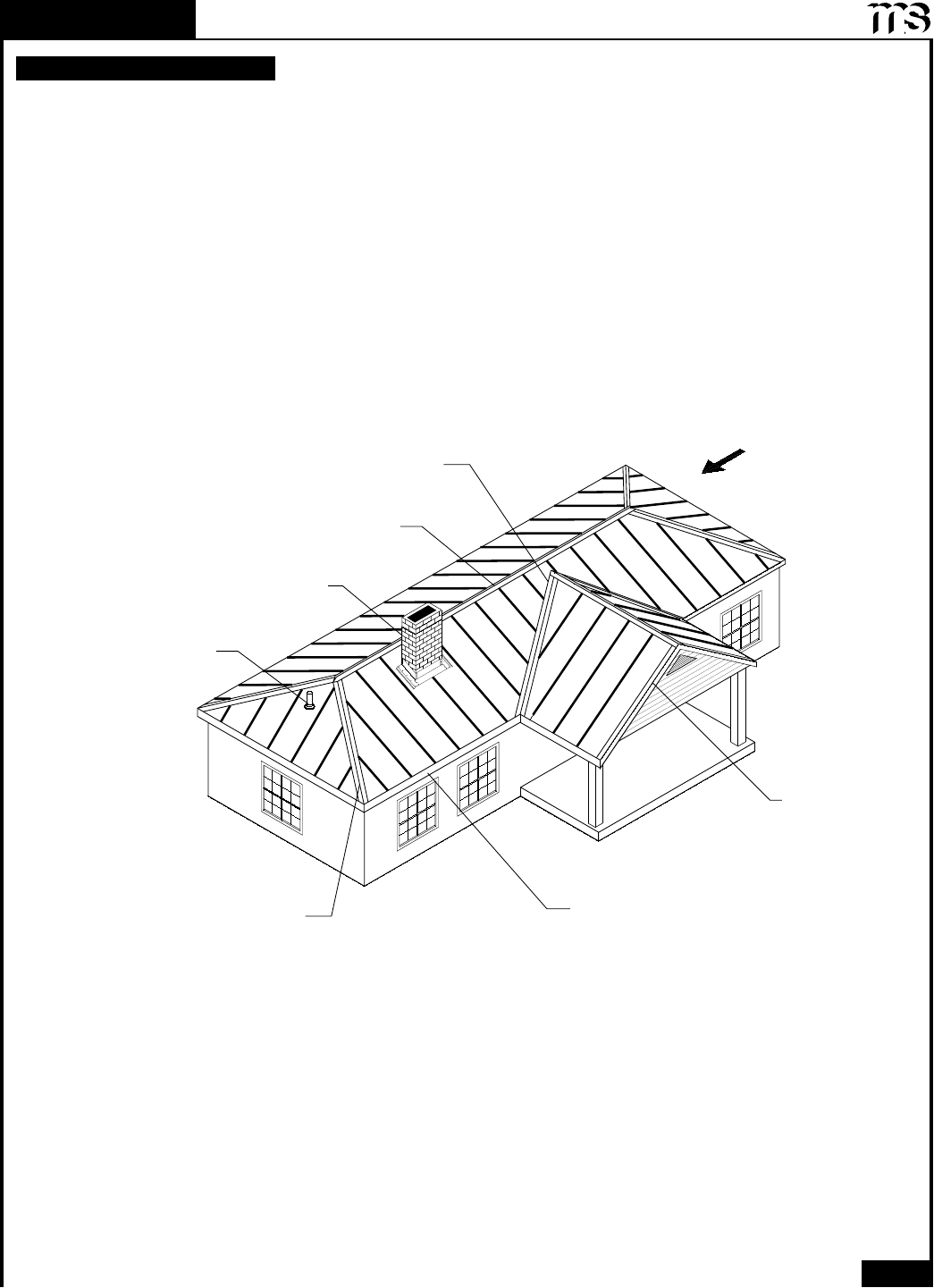

INSTALLATION OVERVIEW

} Asshownbelowwiththenumberdesignations,installpanelagainsttheprevailingwind.

} Makesurepanelsaresquareandplumb,toassurestraightandproperalignmentoftheentirerowofpanels.

} Forareaswithhighwindconsiderations,closerfastenerspacingmayberequired.

} Itisnecessarytoattachatemporaryguidetothefoundationtouseasanalignmentguidewheninstallingsidingpanels.

} Anti-Siphongroovesideofpanelmustbeoverlappedwiththenon-siphongroovesideoftheadjacentpanel(ifapplicable).

INSTALLATION OVERVIEW

1

2

4

3

VALLEY DETAIL

(SEE PAGE 33)

RIDGE DETAIL

(SEE PAGE 32)

EAVE / GUTTER DETAIL

(SEE PAGE 33)

CHIMNEY DETAIL

(SEE PAGE 34)

ROOF PENETRATION

(SEE PAGE 34)

HIP DETAIL

(SEE PAGE 32)

GABLE DETAIL

(SEE PAGE 32)

Prevailing Winds

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

30

CLASSIC RIB

®

RESIDENTIAL PANEL INSTALLATION

INSTALLING FIRST PANEL

INSTALLING INSIDE CLOSURES

INSTALLING

PANEL CLIP

STEP

1

STEP

2

FASTENER

INSIDE CLOSURE

w/ TAPE SEALANT

TAPE SEALANT

INSIDE CLOSURE

ROOF PANEL

1. ApplyarowofTapeSealantacrossthetoplegoftheEaveMoldingalongthewidthof

thebuilding.

2. AlignandplaceInsideClosuresovertheTapeSealant.ItiscriticalthatInsideClosuresaresquareto

buildingasthiswillcontrolthealignmentofthepanels.(Seepage17tocheckbuildingsquare).

3.ApplyarowofTapeSealantacrossthetopoftheInsideClosure(notshownforclarity).

1. InstalltherstpanelovertheInsideClosuretoallowfordesiredoverhang.Makesurethepanelissquare

totheeaveandrake.

2.Fastenthroughpanel,closureandsealantsintodeckingwithappropriateamountoffastenerstomeet

localbuildingcode.(Seefasteningpatternsonpage6).Fastenersmustpenetrateclosureandsealant.

3. Aftersecuringpanelateave,repeatthefasteningpatternattheappropriatespacingtomeetlocal

buildingcodes.

NOTE: -Eave Molding, Gutter and Valley Flashings must rst be installed before panel installation can begin.

-Panels can be installed going from either letf to right or right to left / looking from eave to peak.

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

31

CLASSIC RIB

®

RESIDENTIAL PANEL INSTALLATION

FIRST PANEL INSTALLED

INSTALLING SECOND EAVE PANEL

STEP

3

STEP

4

INSTALLING SECOND PANEL

STITCH SCREW

RIDGE PANEL

EAVE PANEL

TAPE SEALANT

FASTENER

INSIDE CLOSURE

FASTENER

1. ApplyarowofTapeSealantacrossandovertheribsoftherstpanelabout3"frompanelend.

2. InstallthesecondpanelovertherstpanelandTapeSealantwitha6"Endlap.Fastenthroughboth

panelsandTapeSealantintosupportwithappropriateamountoffastenerstomeetlocalbuildingcode.

(Seefasteningpatternsonpage6).Fastenersmustpenetratesealant.

3. Aftersecuringpanelateave,repeatthefasteningpatternattheappropriatespacingtomeetlocal

buildingcodes.

1. Placethelappingseamofthesecondpanelontopofpreviouslyinstalledpanelsothatpanelends

areushateave(Seebelow).

2. Fastenthroughpanel,closureandTapeSealantintosupportwithappropriateamountoffastenersto

meetlocalbuildingcode.(Seefasteningpatternsonpage6).Fastenersmustpenetrateclosureand

sealant.

3. Aftersecuringpanelateave,repeatthefasteningpatternattheappropriatespacingtomeetlocal

buildingcodes.

6"

Anti-Siphon Groove

Side Lap Fastener

(for roof only)

Panel Fastener

Classic Rib Panel

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

32

CLASSIC RIB

®

RESIDENTIAL DETAILS

14" UNIVERSAL RIDGE DETAIL

RIDGE / HIP COVER DETAIL

VENTED RIDGE DETAIL

GABLE TRIM DETAIL

OUTSIDE CLOSURE

STITCH SCREW

(EVERY RIB*)

ROOF PANEL

MOISTURE

BARRIER

TAPE SEALANT

FASTENER

14" UNIVERSAL RIDGE

OUTSIDE CLOSURE (RDG)

UNIVERSAL CLOSURE (HIP)

STITCH SCREW

(EVERY RIB*)

ROOF PANEL

MOISTURE

BARRIER

TAPE SEALANT

FASTENER

RIDGE / HIP COVER

STITCH SCREW

(EVERY RIB*)

ROOF PANEL

MOISTURE

BARRIER

COBRA RIDGE VENT

13" STEP RIDGE COVER

TAPE SEALANT

ROOF PANEL

TAPE SEALANT

MOISTURE BARRIER

GABLE TRIM

FASTENER

OUTSIDE CLOSURE

STITCH SCREW

(EVERY RIB*)

TAPE SEALANT

STITCH SCREW

(1'-0" O.C.)

* FASTENER SPACING TO BE 8" - 12" O.C.

* FASTENER SPACING TO BE 8" - 12" O.C.

* FASTENER SPACING TO BE 8" - 12" O.C.

* FASTENER SPACING TO BE 8" - 12" O.C.

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

33

CLASSIC RIB

®

RESIDENTIAL DETAILS

EAVE DETAIL

GUTTER DETAIL

VALLEY DETAIL

PITCH BREAK DETAIL

FASTENER

ROOF PANEL

TAPE SEALANT

MOISTURE BARRIER

EAVE TRIM

INSIDE CLOSURE

FASTENER

(1'-0" O.C.)

FASTENER

ROOF PANEL

TAPE SEALANT

MOISTURE BARRIER

GUTTER (BY OTHERS)

INSIDE CLOSURE

DRIP EDGE (BY OTHERS)

PANCAKE HEAD SCREW

(1'-0" O.C.)

ROOF PANEL

TAPE SEALANT

MOISTURE

BARRIER

VALLEY

UNIVERSAL CLOSURE

FASTENER

STITCH SCREW

(EVERY RIB*)

WALL PANEL

TAPE SEALANT

MOISTURE

BARRIER

PITCH BREAK

OUTSIDE CLOSURE

ROOF PANEL

FASTENER

* FASTENER SPACING TO BE 8" - 12" O.C.

FASTENER

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

34

CLASSIC RIB

®

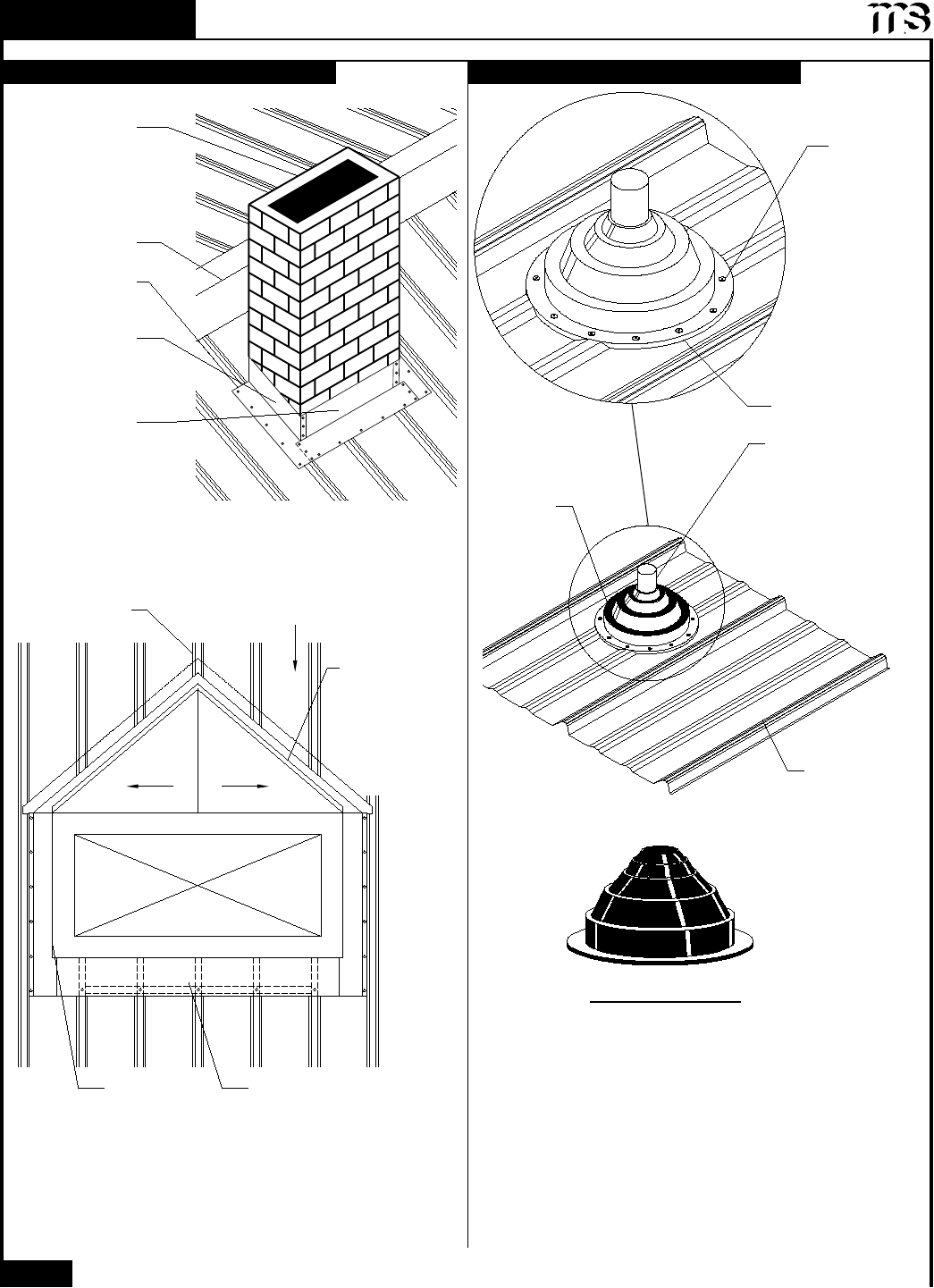

RESIDENTIAL DETAILS

CHIMNEY / CRICKET DETAIL

ROOF PENETRATION DETAIL

TAPE SEALANT

FASTENER

RUBBER

ROOF

JACK

VENT PIPE

ROOF PANEL

MINI (

1

/

4

" TO 1

1

/

8

" O.D. PIPE)

#2 (1

3

/

4

" TO 3" O.D. PIPE)

#4 (3" TO 6" O.D. PIPE)

#6 (6" TO 9" O.D. PIPE)

#8 (7" TO 13" O.D. PIPE)

AVAILABLE SIZES

CHIMNEY

RIDGE / HIP

COVER

ROOF PANEL

SIDEWALL

(FIELD CUT

AND BEND)

ENDWALL

(FIELD CUT

AND BEND)

ROOF PANEL

SLOPE

FIELD

FABRICATE

FLAT SHEET

TO FIT

PLYWOOD

CRICKET

UNIVERSAL

SIDEWALL

UNIVERSAL

ENDWALL

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

35

CLASSIC RIB

®

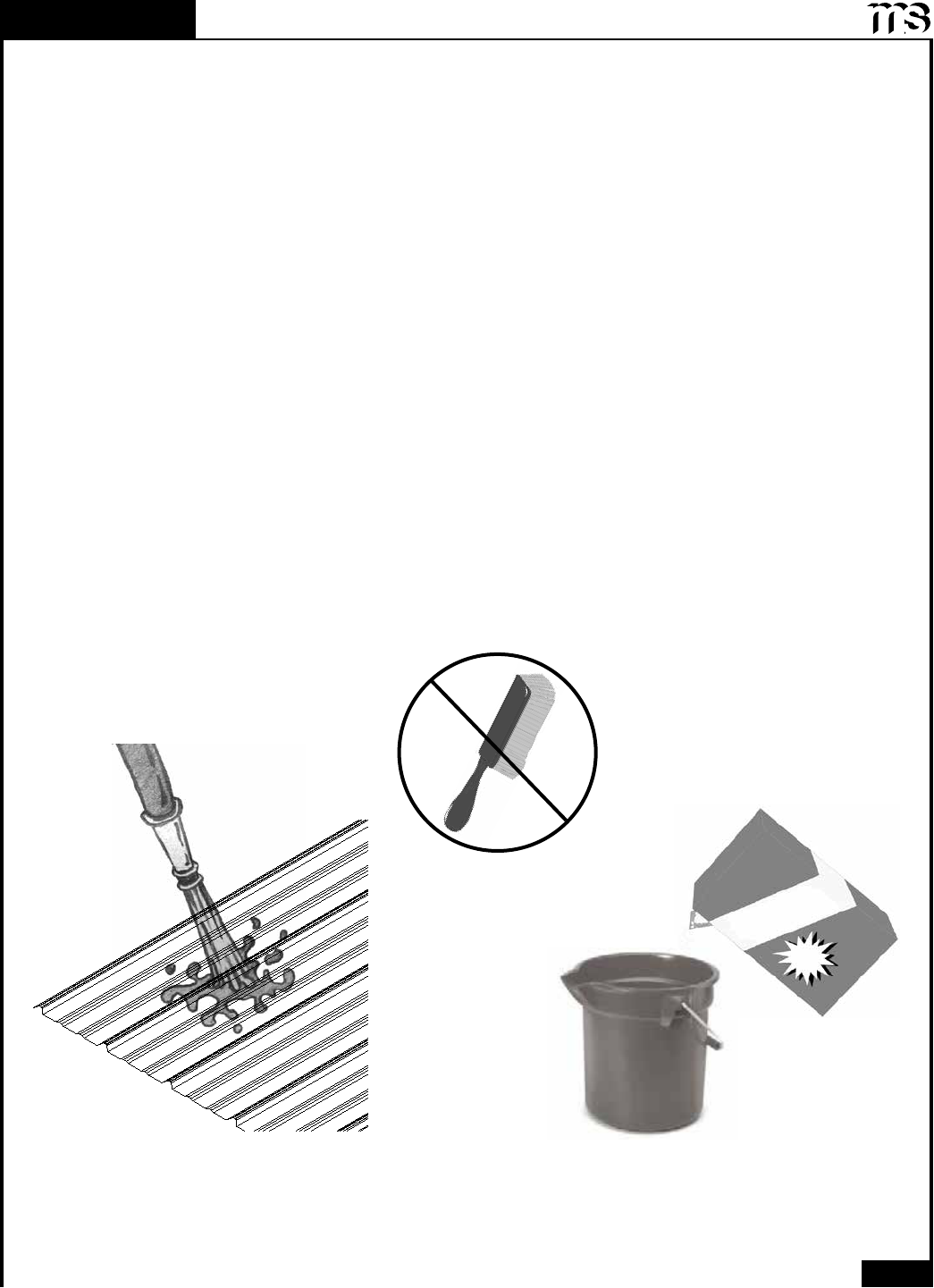

Thoughfactoryappliedprepaintednishesareverydurableandwilllastmanyyears,eventuallyitmaybedesirableto

thoroughlycleanorrepaintthem.

Dirtpickupmaycauseapparentdiscolorationofthepaintwhenithasbeenexposedinsomedirt-ladenenvironmentsforlong

periodsoftime.Inareasofstrongsunlight,slightchalkingmaycausesomechangeinappearance.Agoodcleaningwilloften

restoretheappearanceofthesebuildingsandrenderrepaintingunnecessary.Anoccasionallightcleaningwillhelpmaintaina

goodappearance.

Inmanycases,simplywashingthebuildingwithplainwaterusingahoseorpressuresprayerwillbeadequate.Inareas

whereheavydirtdepositsdullthesurface,aclothorsoftbristlebrushandsolutionofwateranddetergent(

1

/

3

cupoflaundry

detergentpergallonofwaterforexample)maybeused.Thisshouldbefollowedbyanadequaterinseofwater.Donotuse

wirebrushes,abrasives,orcleaningtoolswhichwilldamagethecoatingsurface.

Mildewmayoccurinareassubjecttohighhumiditybutisnotnormallyaproblemduetothehighinherentmildewresistance

ofthebakednishthatisused.Toremovemildewalongwiththedirt,thefollowingsolutionisrecommended.

1

/

3

cupdetergent(Tide

®

orequivalent)

2

/

3

cuptrisodiumphosphate(Solex

®

orequivalent)

1quartof5%sodiumhypochloritesolution(Clorox

®

orequivalent)

3quartsofwater

Strongsolventsandabrasivetypecleanersshouldbeavoided.Mostorganicsolventsareammableandtoxicandmustbe

handledaccordingly.Whenusingasolvent,consultmaintenanceprofessionalsandlabelinstructionsforproperhandling

anddisposalofwashings.Ifrequired,amildsolventsuchasmineralspiritscanbeusedtoremovecaulkingcompounds,

oil,grease,tars,wax,andsimilarsubstances.Useaclothdampenedwithmineralspiritsandapplyonlytoareaswhichare

contaminated.Followuptheuseofthismildsolventwithdetergentcleaningandrinsing.

CARE AND MAINTENANCE

DO NOT USE A

WIRE BRUSH

HOSE OR PRESSURE SPRAY

FOR ADEQUATE CLEANING

USE MILD DETERGENT AND WATER

FOR HEAVY DIRT DEPOSITS

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

36

CLASSIC RIB

®

NOTES

© Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19

37

CLASSIC RIB

®

NOTES